An eccentric shaft gooseneck trunk hinge, trunk lid assembly and vehicle

A technology for trunk hinges and trunk lids, which is applied to hinges with pins, door/window fittings, hinges, etc., can solve the problems of low adjustment freedom and complicated installation procedures, so as to improve production efficiency and reduce work The effect of intensity, adjustment and positioning quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

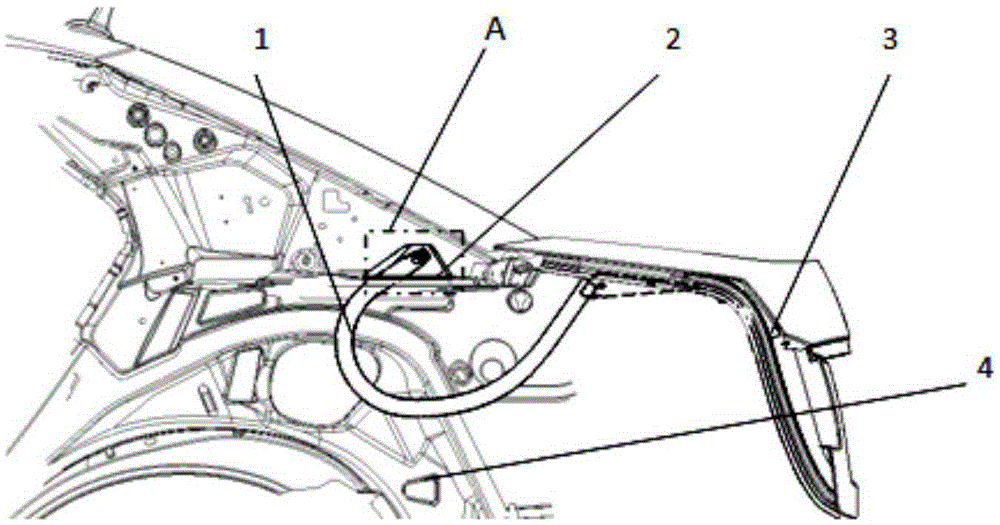

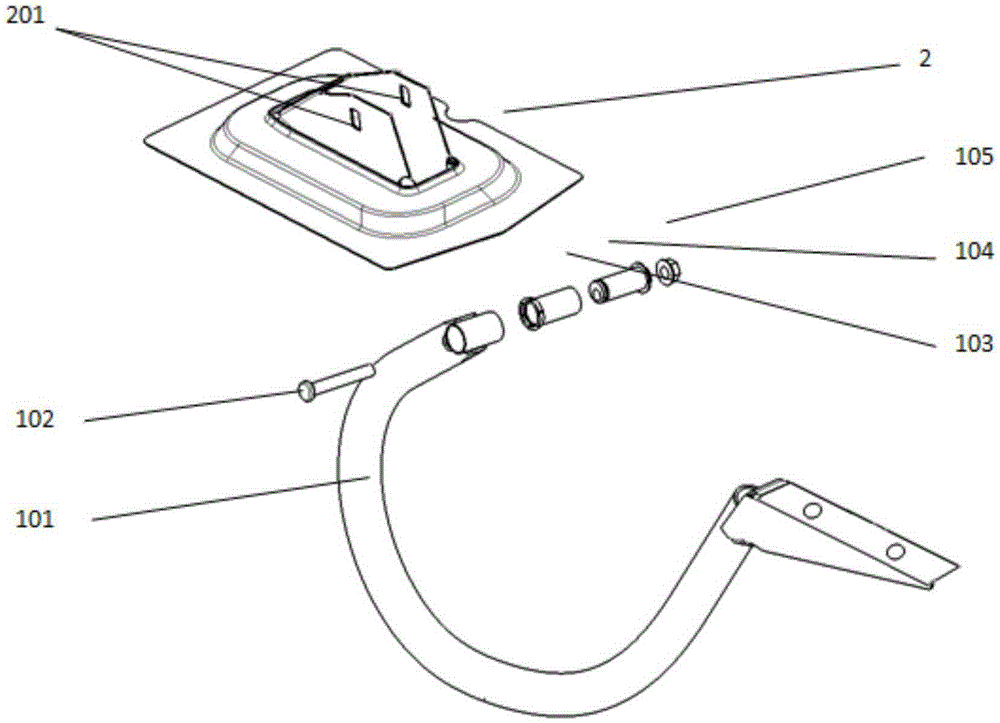

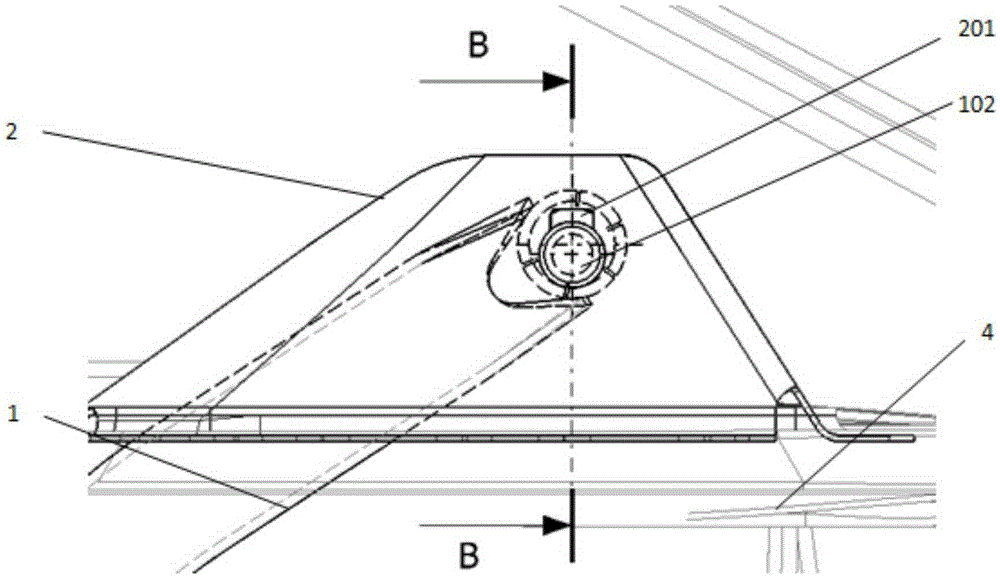

[0031] Aiming at the problem that the existing trunk lid assembly is very inconvenient to install, the invention proposes an eccentric shaft gooseneck trunk hinge, a trunk lid assembly and a vehicle. Among them, such as figure 1 , figure 2 , image 3 As shown, the eccentric shaft gooseneck luggage hinge 1 includes a gooseneck-shaped connecting rod 101, one end of the connecting rod 101 is provided with an eccentric shaft to connect the mounting seat 2 on the vehicle body 4, and the other end is connected to the luggage compartment. box cover 2; as image 3 As shown, the mounting seat 2 is provided with a hinge adjustment rectangular hole 201 extending vertically along the long axis. Such as figure 1 As shown, the connecting rod includes a semicircu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com