Drill working state automatic identification method suitable for hydraulic drill

An automatic identification and hydraulic drilling rig technology, which is applied in the field of mud logging, oil and gas exploration and development drilling, can solve problems such as inaccurate state judgment, and achieve the effect of automatic identification and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Preferred embodiments of the present invention will be specifically described below.

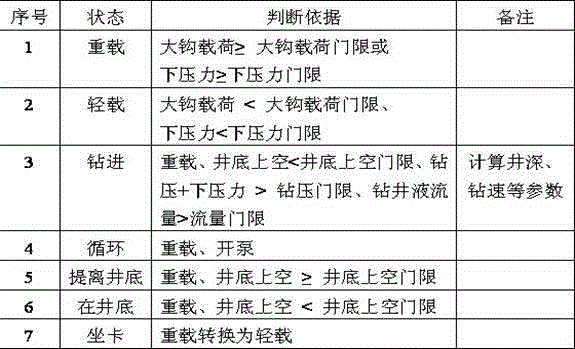

[0038] The present invention provides a drilling rig working state automatic identification method suitable for hydraulic drilling rigs, the automatic identification method includes the following steps:

[0039] Step 1. Install the suspension load sensor for measuring the load of the hook, the winch sensor for measuring the displacement of the hook, and the pumping sensor for measuring the flow rate of the drilling fluid on the corresponding position of the hydraulic drilling rig according to the conventional method;

[0040] Step 2. Connect a three-way joint in series to the pressure sensor for measuring the down pressure in the connection oil circuit of the down pressure gauge of the hydraulic drilling rig;

[0041] Step 3. The conventional signal receiving and processing module receives the hook load value measured by the suspension weight sensor, the hook displacement value measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com