Method and device for measuring channel of guide vane with welded structure

A technology of guide vanes and welded structures, applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of unreadable measurement data, low measurement efficiency, and low measurement accuracy, so as to reduce inaccurate measurement data and improve measurement accuracy , the effect of accurate measurement basis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

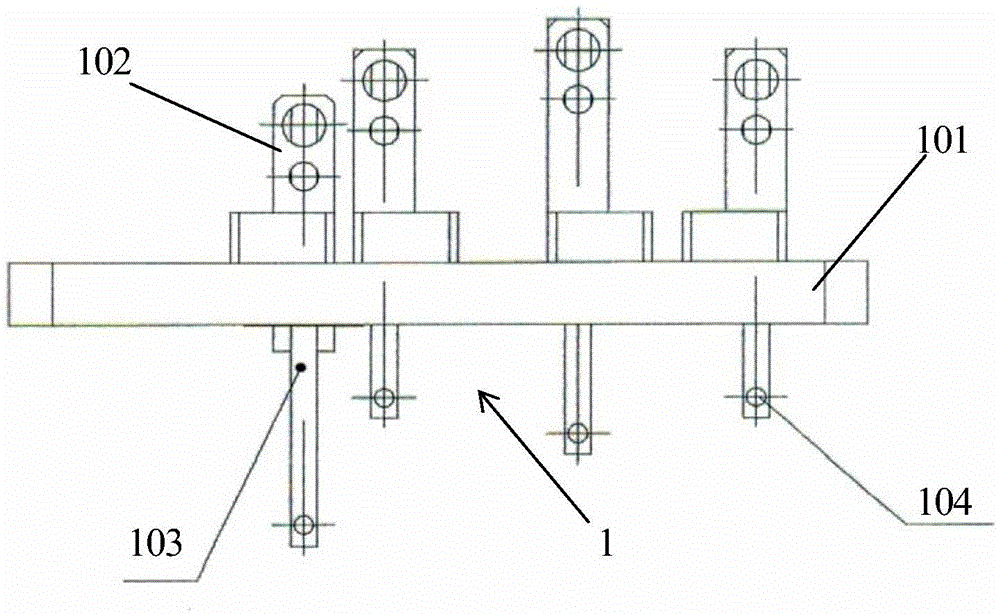

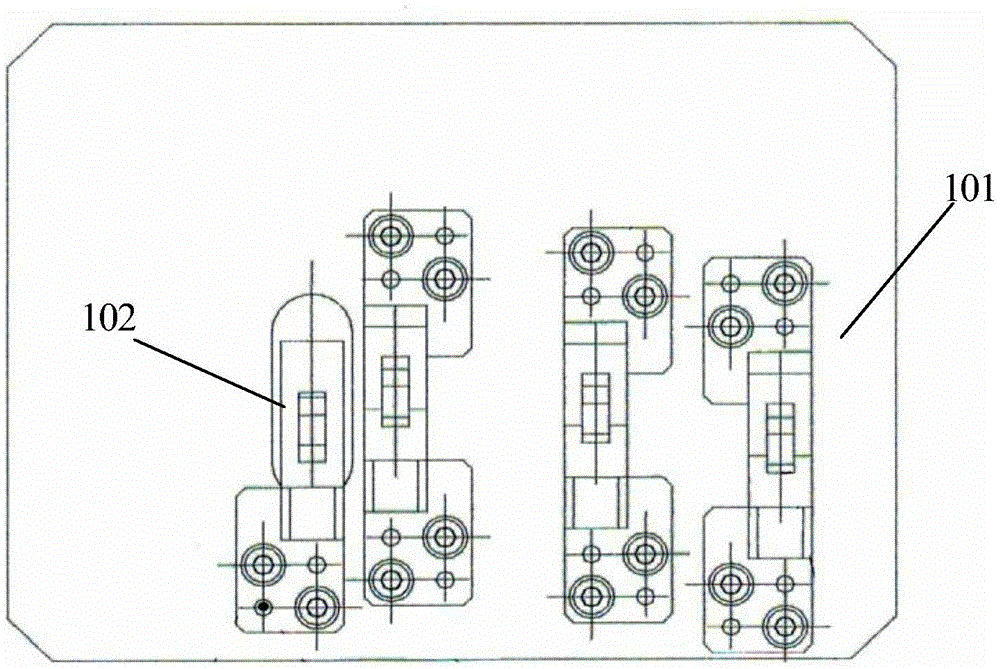

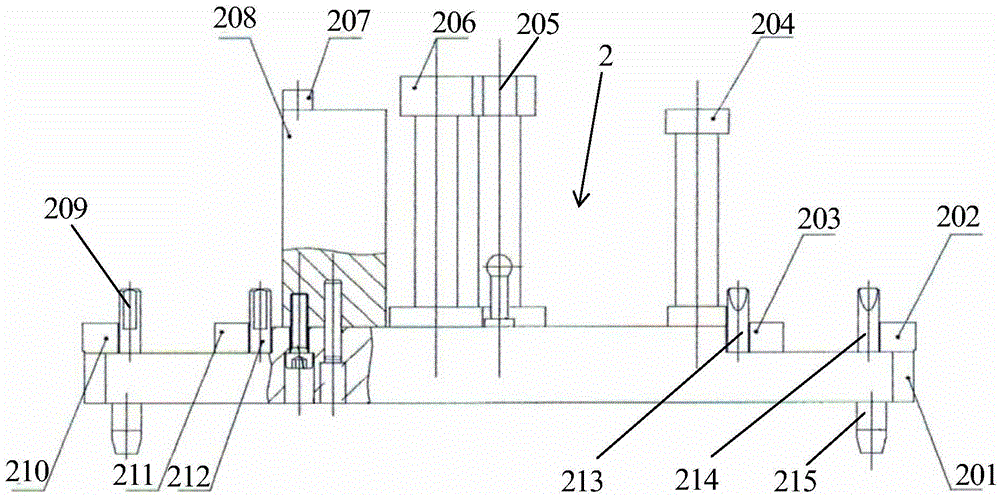

[0037] Such as Figure 1-Figure 6 As shown, the welding structure guide vane channel measuring device of the present invention is structurally divided into three parts: a table base device 1, a standard part device 2 for the table, and a measuring tool device 3. The table base device 1 is installed on the standard part device 2 , after realizing the theoretical calibration of the table base device 1, install the table base device 1 on the measuring tool device 3 to measure the guide vane channel, as follows:

[0038] Such as Figure 1-Figure 2 As shown, the structure of the table base device 1 is used to measure the actual value of the channel point. The specific structure of the table base device 1 is as follows: each table base device 1 is provided with one to four percentage points with the function of installing a dial indicator on the substrate 101. Table installation base 102, the dial gauge installed on table base device 1 is matched with lever 103 to form the lever mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com