Motor deviation detection method and application thereof

A motor and deviation technology, applied in the field of motor deviation detection, can solve problems such as unfavorable motor control, deviation of motor output torque, affecting the detection accuracy of electrical appliances, etc., to improve detection accuracy, ensure laundry quality, strong versatility and The effect of operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

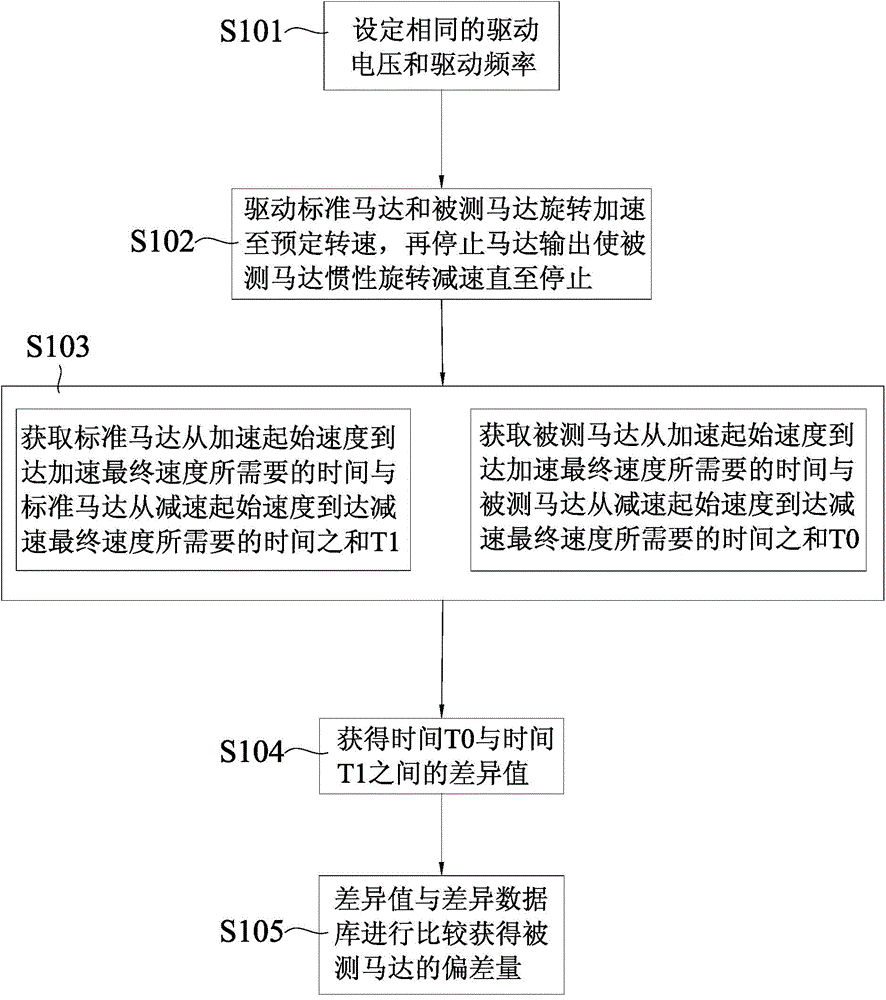

[0031] refer to figure 1 , embodiment one, the detection method of motor deviation:

[0032] S101: setting the same driving voltage and driving frequency;

[0033] S102: Drive the standard motor and the measured motor to rotate and accelerate to a predetermined speed, and then stop the motor output to make the measured motor inertial rotation decelerate until it stops;

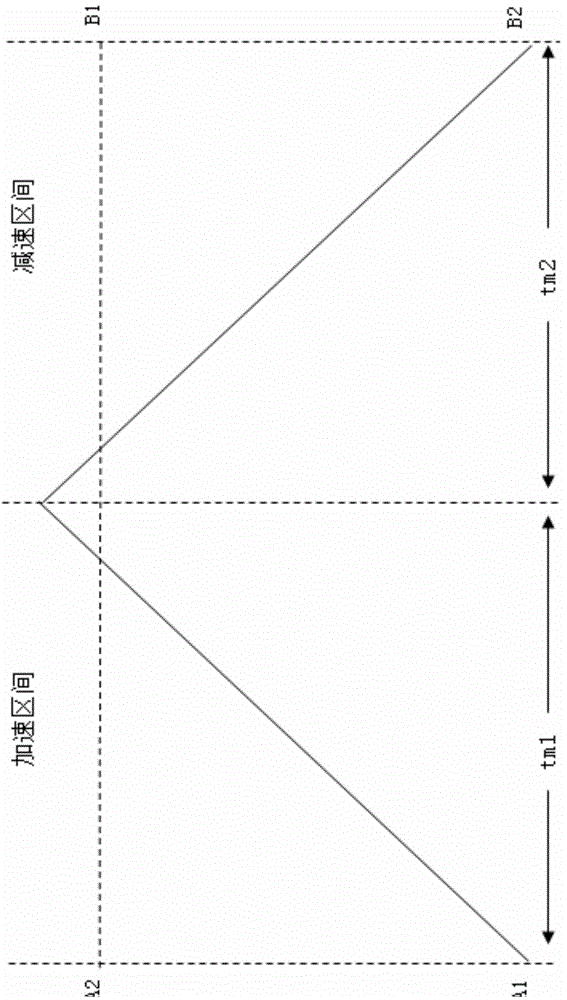

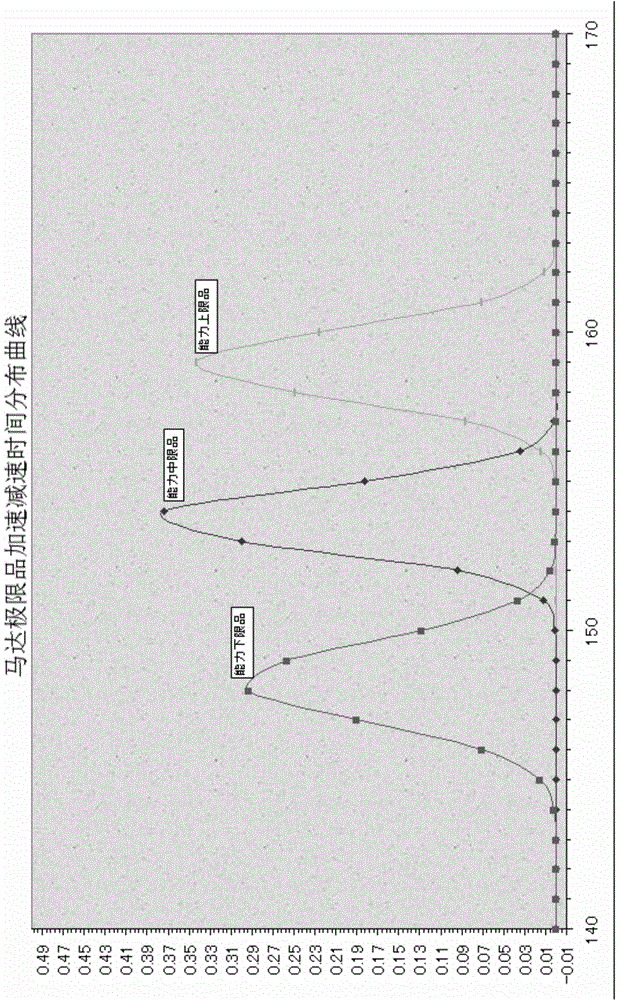

[0034] S103: In the acceleration and deceleration interval, set the first rotational speed as the initial acceleration speed, set the second rotational speed as the final deceleration speed, and obtain the time required for the standard motor to reach the final acceleration speed from the initial acceleration speed and the deceleration final speed of the standard motor. The sum of the time T required for the initial speed to reach the deceleration final speed 1 , to obtain the sum T of the time required for the motor under test to reach the final speed of acceleration from the initial speed of acceleration a...

Embodiment 2

[0049] refer to Figure 7 , embodiment two, the detection method of motor deviation:

[0050] S201: setting the same driving voltage and driving frequency;

[0051] S202: Drive the standard motor and the measured motor to rotate and accelerate to a predetermined speed, and then stop the motor output to make the measured motor inertial rotation decelerate until it stops;

[0052] S203: In the acceleration interval, set the first rotational speed as the initial acceleration speed, set the second rotational speed as the final acceleration speed, and obtain the time T required for the standard motor to reach the final acceleration speed from the initial acceleration speed 1 , to obtain the time T required for the measured motor to reach the final acceleration speed from the initial acceleration speed 0 ;

[0053] S204: Obtain time T 0 with time T 1 difference between

[0054] S205: The difference value is compared with the difference database to obtain a deviation amount of ...

Embodiment 3

[0057] refer to Figure 8 , embodiment three, detection method of motor deviation:

[0058] S301: setting the same driving voltage and driving frequency;

[0059] S302: Drive the standard motor and the tested motor to rotate and accelerate to a predetermined speed, and then stop the motor output to make the tested motor inertial rotation decelerate until it stops;

[0060] S303: In the deceleration interval, set the first rotational speed as the deceleration initial speed, set the second rotational speed as the deceleration final speed, and obtain the time T required for the standard motor to reach the deceleration final speed from the deceleration initial speed 1 , to obtain the time T required for the measured motor to reach the final deceleration speed from the deceleration initial speed 0 ;

[0061] S304: Obtain time T 0 with time T 1 difference between

[0062] S305: The difference value is compared with the difference database to obtain a deviation amount of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com