Auxiliary umbrella installing method and auxiliary umbrella

An installation method and umbrella skirt technology are applied to the installation method of auxiliary umbrellas and the field of auxiliary umbrellas, which can solve the problems of limited service life, inability to fundamentally guarantee long-term operation, and high cost, and achieve the effect of long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

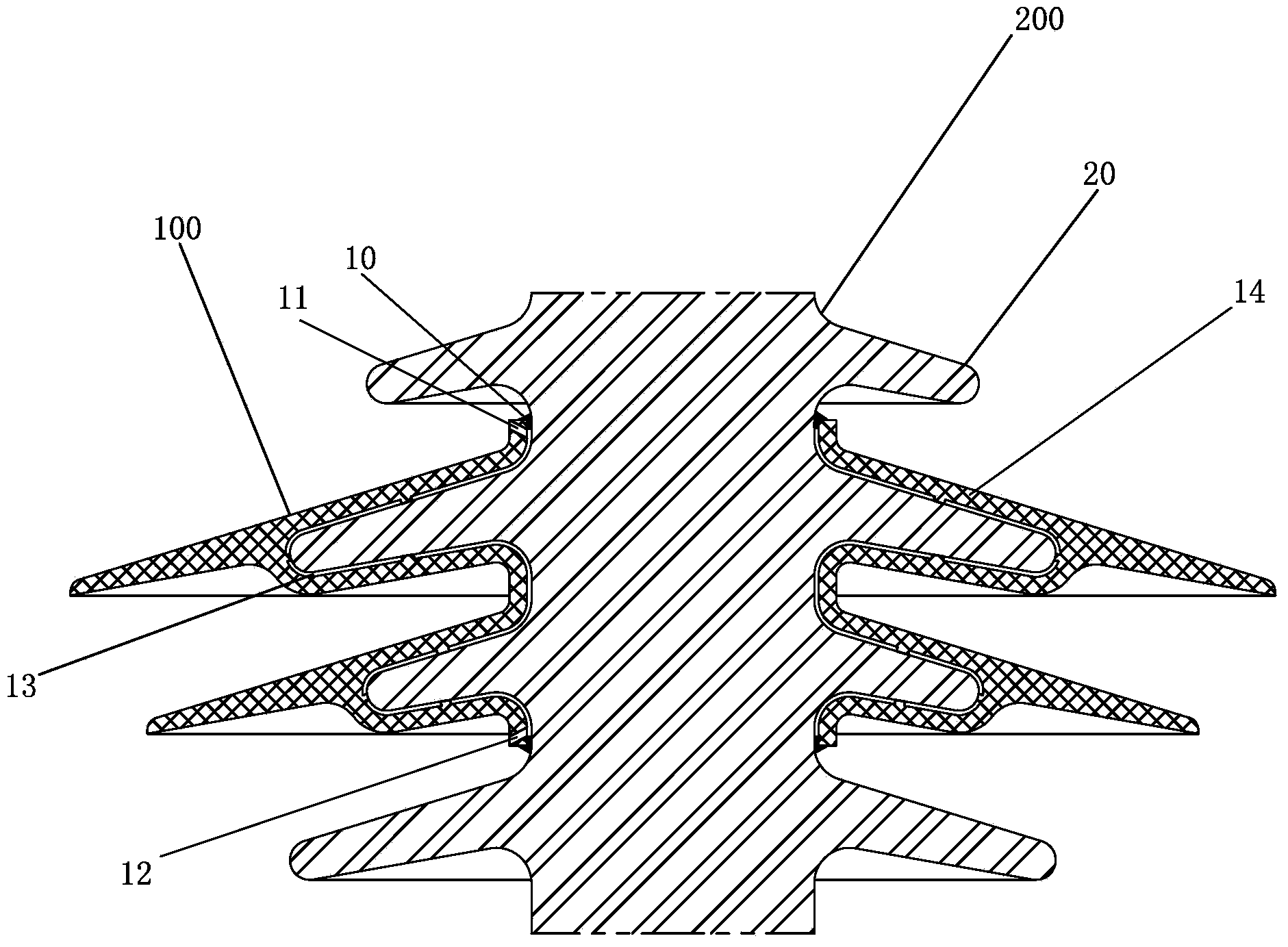

[0020] Such as figure 1 As shown, it is a schematic diagram of the auxiliary umbrella 100 sleeved on the insulator 200 in this embodiment. The insulator 200 includes several sheds 20 . The auxiliary umbrella 100 includes a fixed portion 14 covering the upper surface of the shed 20 , the upper end of the fixed portion 14 is provided with an air vent 11 , and the lower end of the auxiliary umbrella 100 is provided with a glue injection hole 12 . Blocking objects 10 are provided at positions where the upper and lower ends of the auxiliary umbrella 100 are in contact with the insulator 200 . A space 13 is provided on the surface of the auxiliary umbrella 100 and the umbrella skirt 20 for subsequent filling of glue.

[0021] The installation method of the auxiliary umbrella of the present embodiment comprises the following steps:

[0022] a. Set the auxiliary umbrella 100 on the umbrella skirt 20;

[0023] b. The upper and lower ends of the auxiliary umbrella 100 connected with...

Embodiment 2

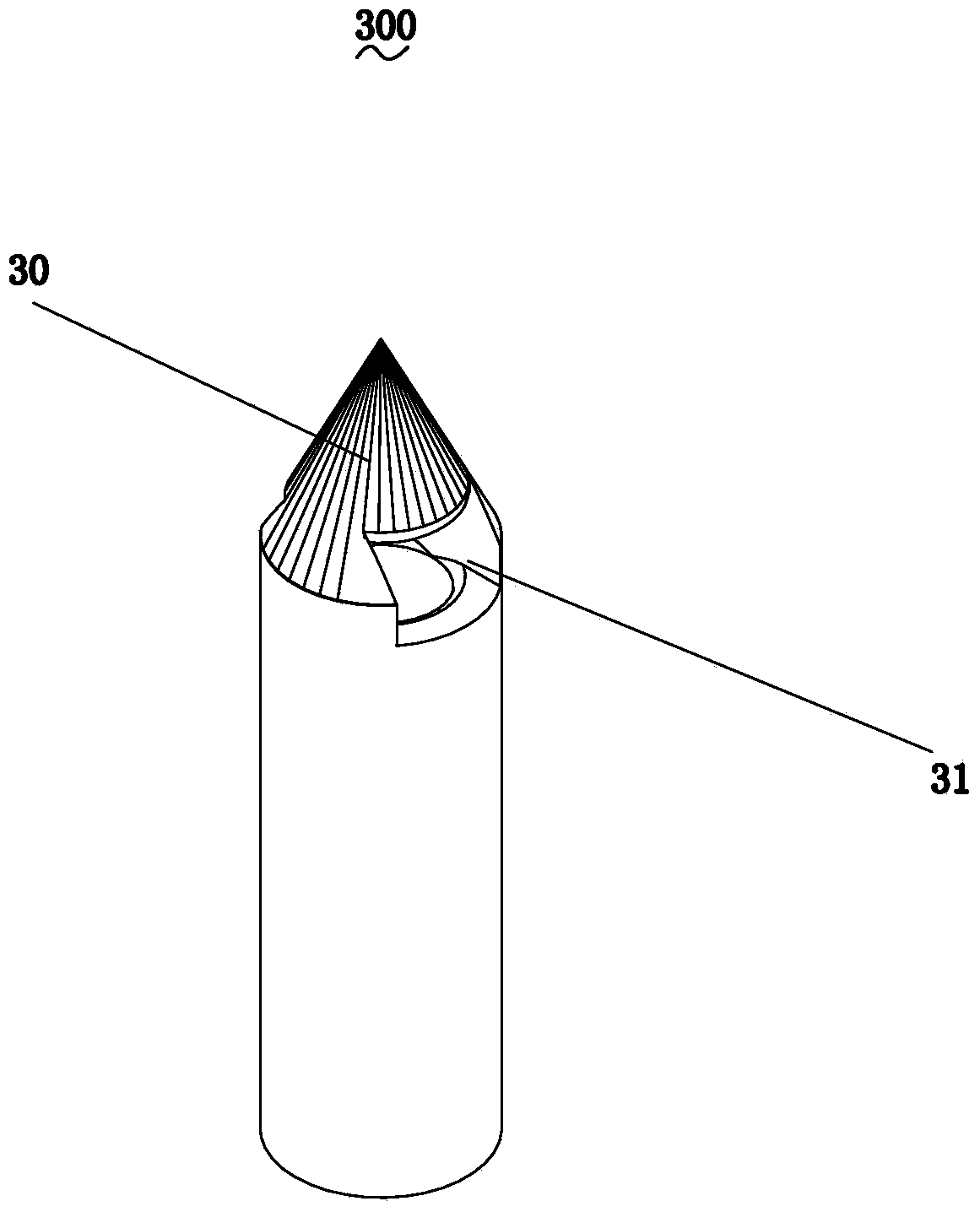

[0028] Such as figure 2 Shown is a schematic diagram of the needle 300 used in the second embodiment of the present invention. A tip 30 is provided on the needle 300 for piercing the auxiliary umbrella, and the other end of the needle 300 is connected with a glue injection tube. A glue outlet 31 is provided on the side of the tip 30, and the glue outlet 31 is arranged on the side to facilitate the smooth flow of the glue from the needle 300 without being blocked. The lower part of the auxiliary umbrella of the present embodiment does not need to reserve a glue injection hole.

[0029] The installation method of the auxiliary umbrella of the present embodiment comprises the following steps:

[0030] a. Set the auxiliary umbrella cover on the umbrella skirt;

[0031] b. Seal the upper and lower ends of the auxiliary umbrella and the insulator with plugging materials, seal the opening of the auxiliary umbrella, and reserve the vent hole on the upper part of the auxiliary umbr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com