An internal locking module of a circuit breaker

A circuit breaker and locking end technology, applied in the low-voltage electrical field, can solve problems such as poor reliability, and achieve the effects of convenient operation, strong reliability and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

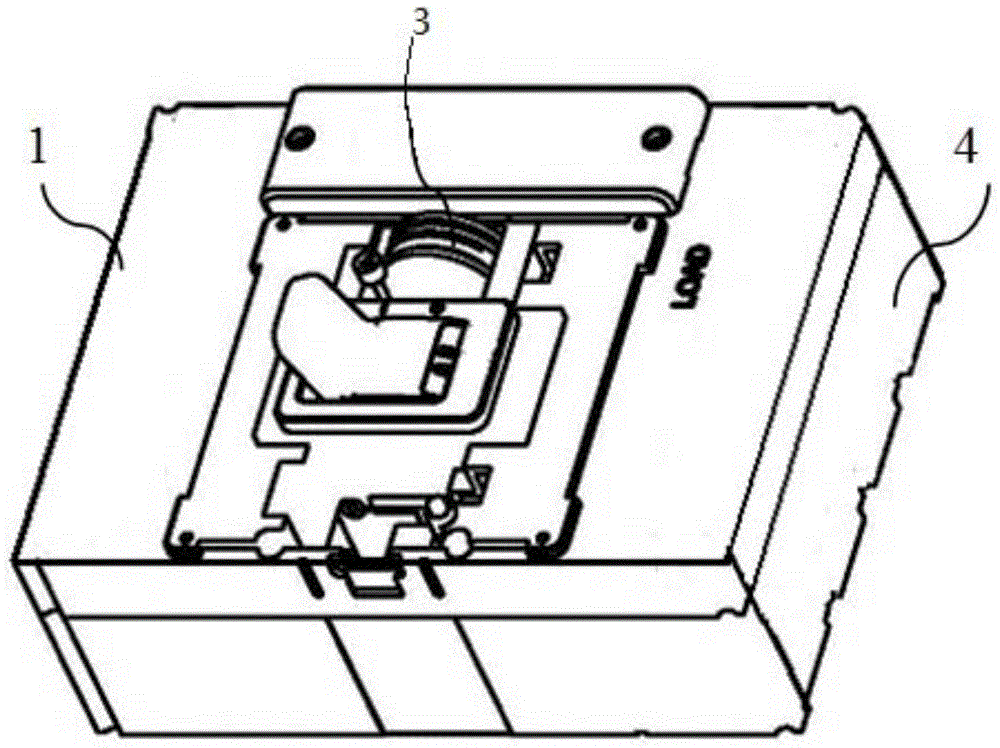

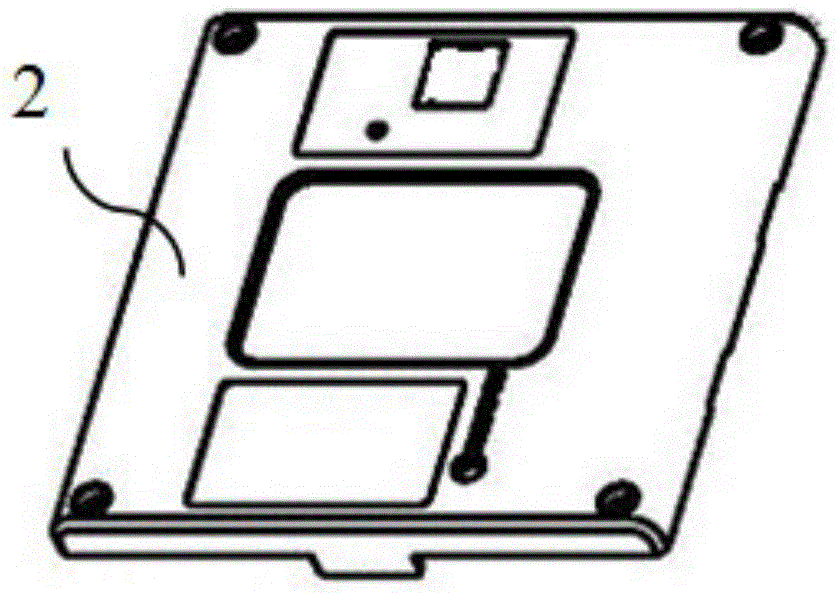

[0041] Such as figure 1 Shown is a preferred embodiment of the internal locking module of a circuit breaker of the present invention. The internal locking module is set in the accessory box 7 of the circuit breaker 4, and the accessory box 7 is set on the middle cover 1. After the locking module is assembled, the upper cover 2 can be used, such as figure 2 shown.

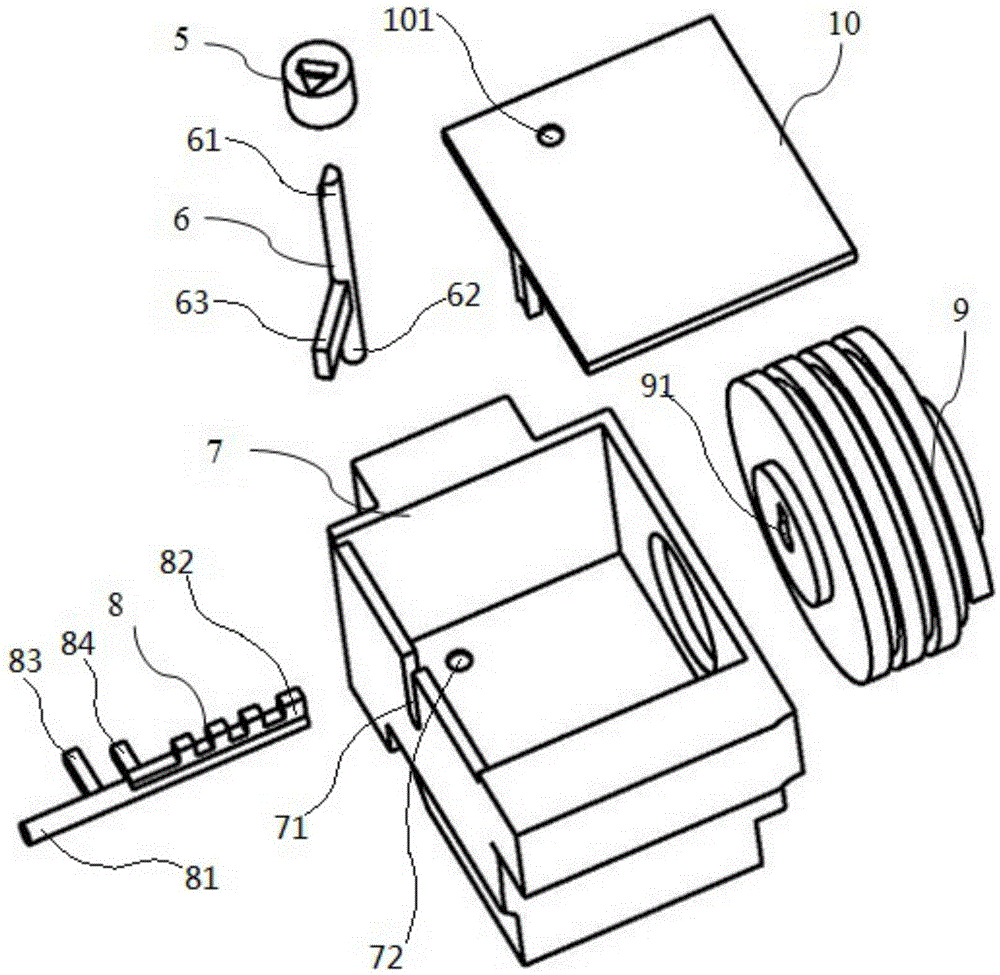

[0042] Such as image 3 As shown, the locking module 3 includes a lock cylinder 8, a lock cylinder limiting mechanism and a lock cylinder driving mechanism.

[0043] The lock core 8, or called a latch, has one end of the lock core 8 as a locking end 81 and the other end as a mounting end 82, and a suitable surface is formed on the side wall of the accessory box 7 close to the handle 19 of the circuit breaker. The lock cylinder hole 71 protruding from the locking end 81, the locking end 81 protruding from the lock cylinder hole 71 is suitable for cooperating with the handle 19 to lock the handle 19, specifically,...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the length of the locking end 81 of the lock cylinder 8 in this embodiment is suitable for sequentially locking the lever 11 of the handle 19, the bracket 12 of the circuit breaker 4 and the jumper. 13. To play the role of locking circuit breaker tripping protection, suitable for marine circuit breakers to prevent unnecessary tripping due to circuit breaker vibration. The lock cylinder limiting mechanism includes a side wall opposite to the lock cylinder hole 71 , a first baffle plate 83 and a second baffle plate 84 .

[0052] Such as Figure 7 As shown, the side wall of the lock cylinder hole 71 is provided with an assembly hole for inserting the installation end 81 of the lock cylinder 8 to support the installation end 81 .

[0053] The first baffle plate 83 and the second baffle plate 84 are arranged on the lock core 8 , and the first baffle plate 83 and the second baffle plate 84 protrude from the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com