a screen

A technology of sieve mesh and sieve mesh plate, which is applied in the direction of filter sieve, solid separation, grille, etc., can solve the problems of no large development, material hanging and blocking, etc., and achieve easy processing, simple process, and reduced broken The effect of the possibility of film hanging material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

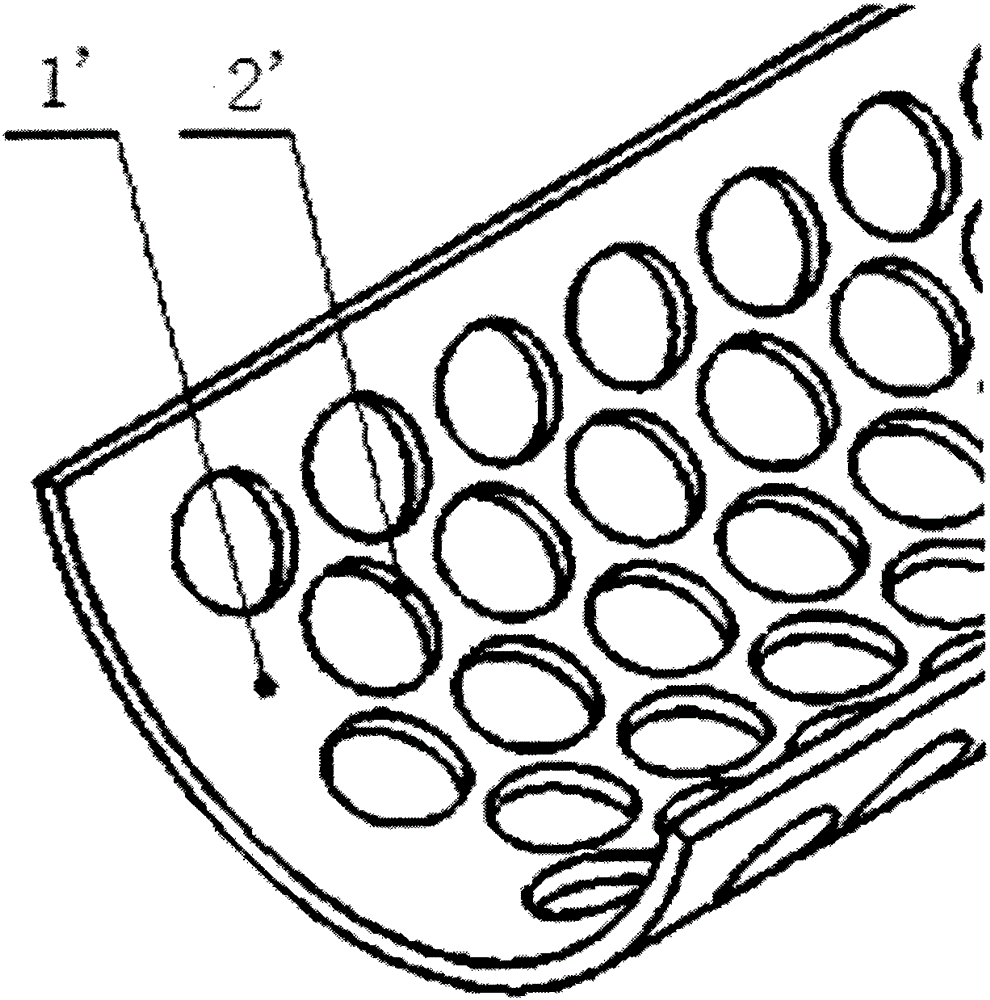

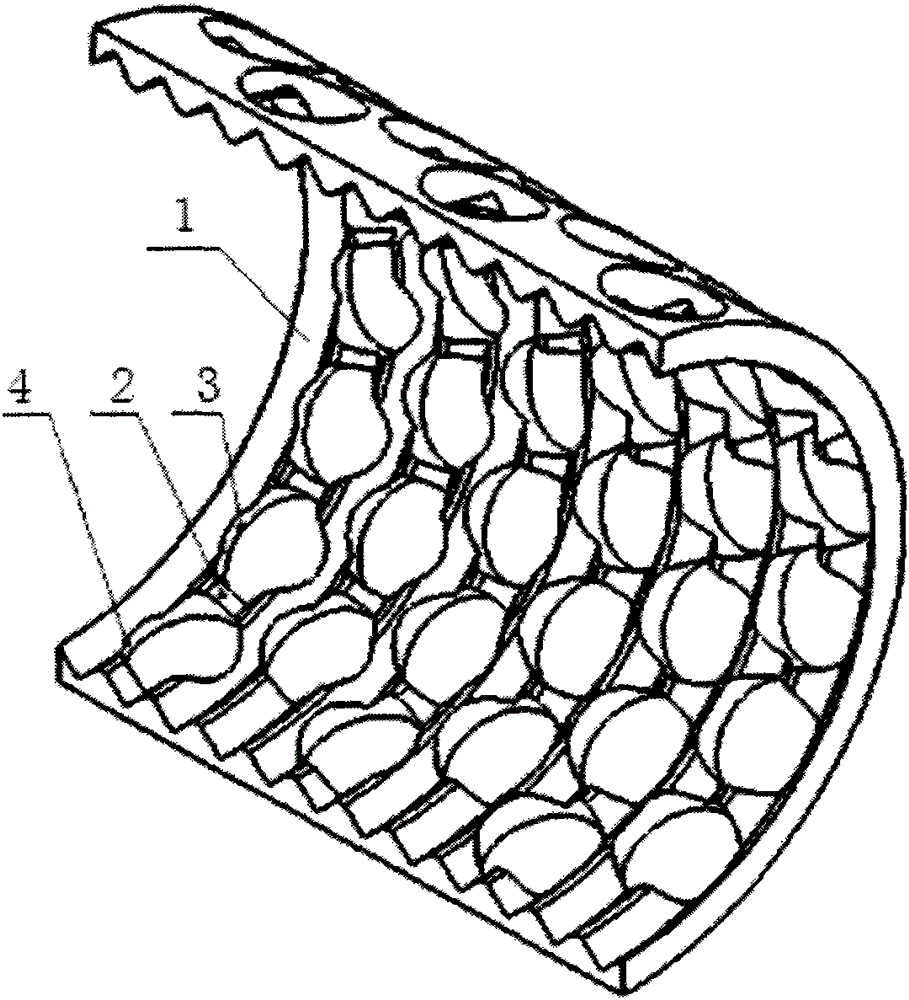

[0010] Such as figure 2 As shown, it is a structural schematic diagram of a screen of the present invention, which is provided with a screen plate 1, and the array of said screen plate 1 is provided with a plurality of V-shaped cone surfaces 2 and a plurality of screen holes 3, so that The edge of the screen hole 3 is an intersecting arc surface 4 , and the intersecting arc surface 4 is arranged on the V-shaped conical surface 2 .

[0011] When processing a screen of the present invention, the screen plate pipe material is first cut into a required arc shape, and after punching, the workpiece only needs to be placed on a lathe for lathe processing, and the shape of the screen of the invention can be turned.

[0012] The screen of the present invention does not change the shape and size of the screen hole 2 under the premise that the quality of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com