PC (Poly carbonate) milling cutter for plastics

A technology for milling cutters and plastics, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of affecting product processing quality and inconvenient chip removal, and achieve the effect of facilitating discharge and reducing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

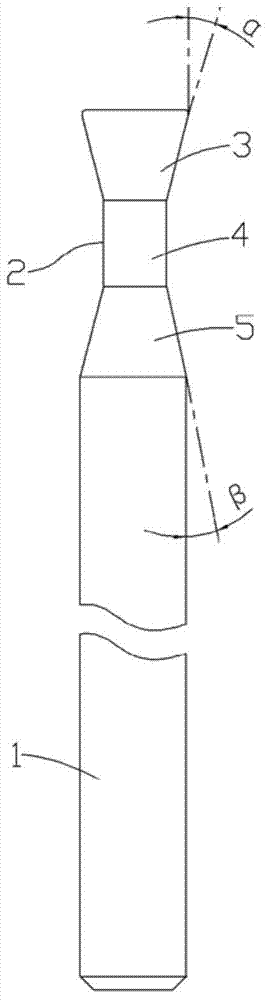

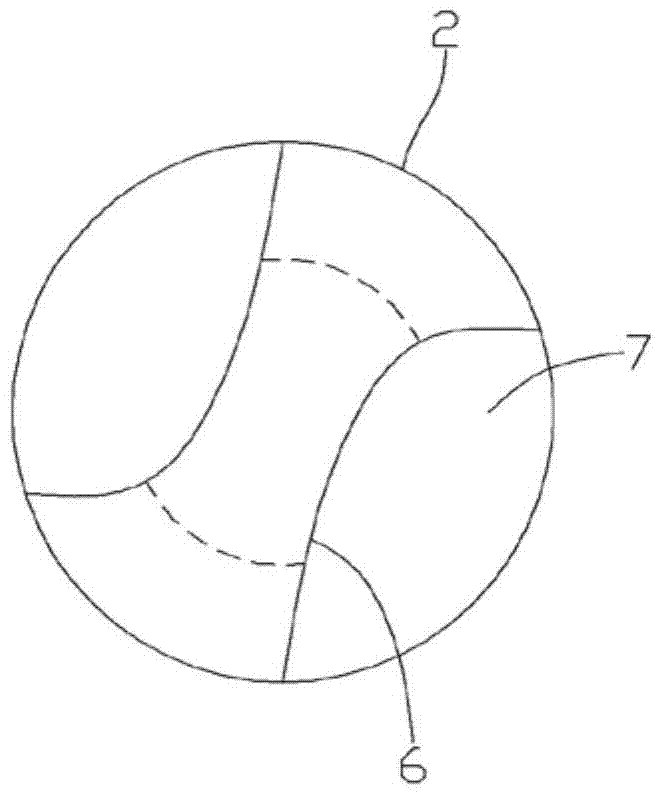

[0013] See figure 1 with figure 2 As shown: the plastic PC milling cutter of the present invention includes a handle 1, a cutter head 2 is formed on the handle 1, and the cutter head 2 is composed of a dovetail groove-shaped blade connecting portion 5, a vertical second blade portion 4 and an inverted dovetail The grooved first blade part 3 is formed, the blade connecting part 5 is formed on the handle 1, and the two ends of the second blade part 4 are respectively connected on the blade connecting part 5 and the first blade part 3, and the first blade There are two straight-toothed knife teeth 6 in the shape of an ax head on the top surface of the part 3, and a chip flute 7 is formed between two adjacent knife teeth 6, and the said knife teeth 6 run through the first knife edge part 3 and the second knife edge part 4 .

[0014] The included angle α between the side edge formed on the second blade portion 4 of the cutter tooth 6 and the central axis of the cutter head 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com