Anti-collision tool changer

A tool magazine and anti-collision technology, which is applied in the field of mechanical processing, can solve problems such as tool damage, personnel injury, and knife collision, and achieve the effects of improving production efficiency and safety, and preventing knife collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

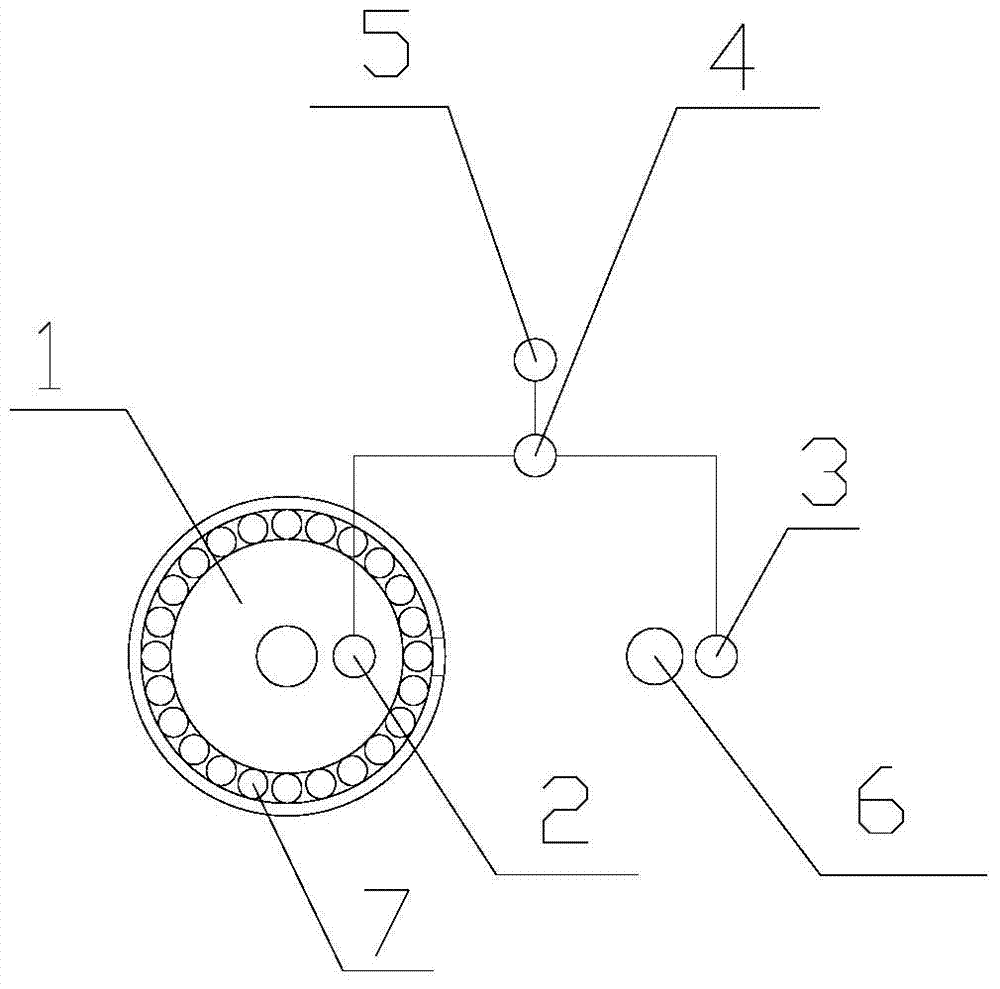

[0009] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an anti-collision tool magazine proposed by the present invention.

[0010] refer to figure 1 , a kind of anti-collision tool magazine proposed by the present invention is used for numerical control machining center, including cutterhead 1, the tool magazine body installed on cutterhead 1, knives and control device 4, movable warehouse door is installed on cutterhead 1 , the tool magazine body is provided with a plurality of tool installation positions 7, the tools are installed on the tool installation positions 7, the cutter head 1 is provided with a first sensing part 3 and a second sensing part 2, the first sensing part 3 senses Detect whether a tool is installed on the main shaft 6, and the second sensing part 2 senses whether a tool is installed on the tool installation position 7 corresponding to the above-mentioned main shaft 6, and the first sensing part 3 and the second sensing part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com