Attaching mechanism of foam attaching device used for touch screen

A technology of laminating device and touch screen, applied in the input/output process of data processing, instruments, electrical and digital data processing, etc. Efficiency, high degree of automation, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the invention.

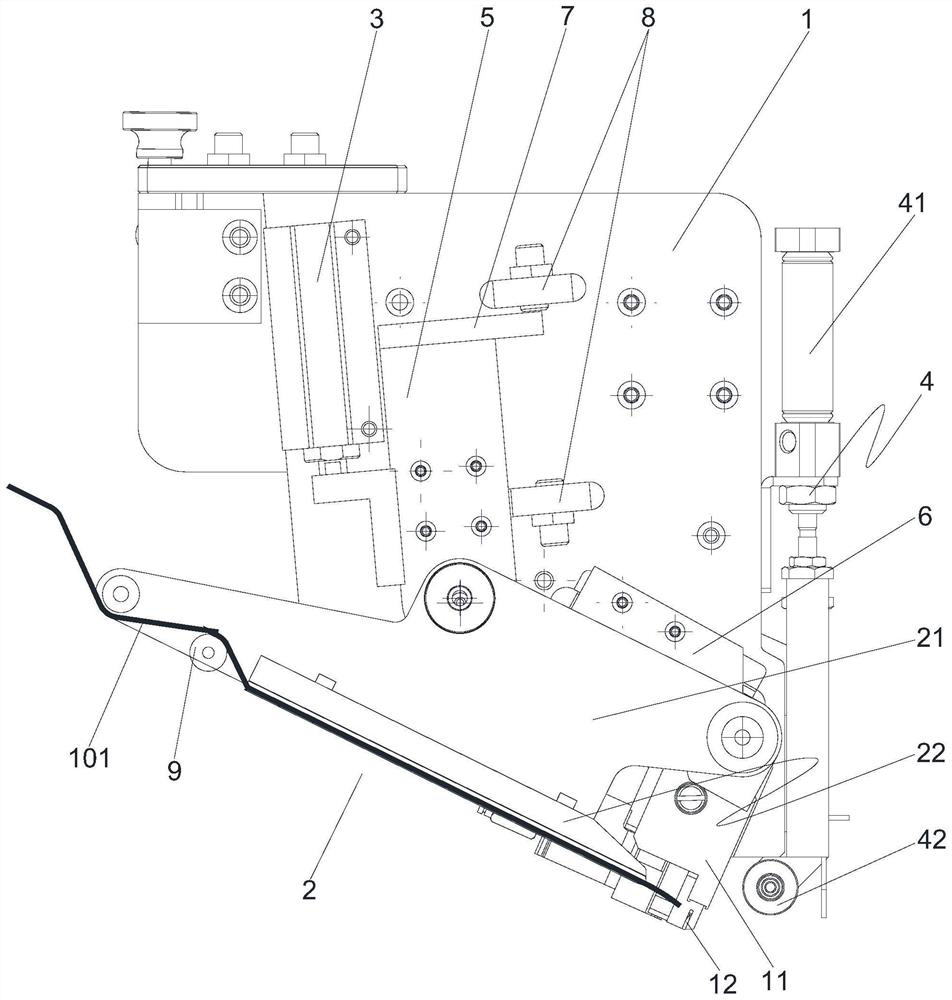

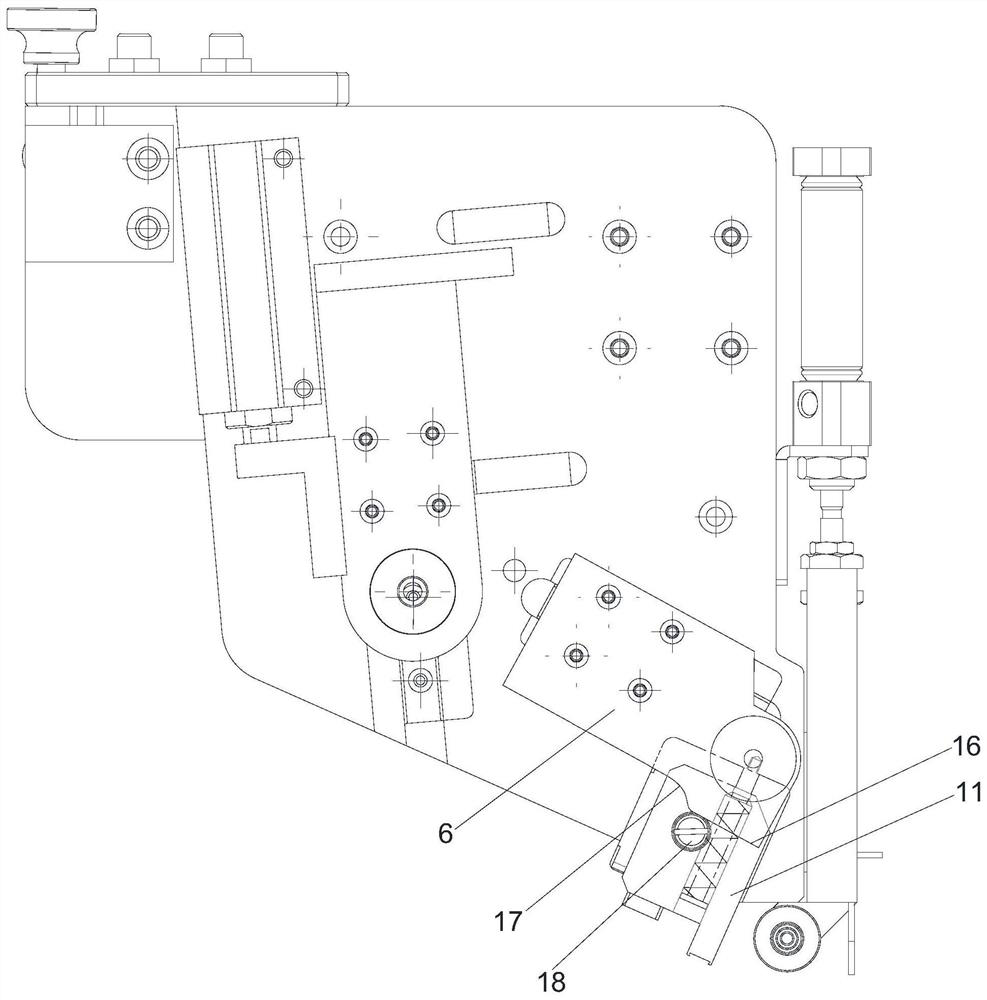

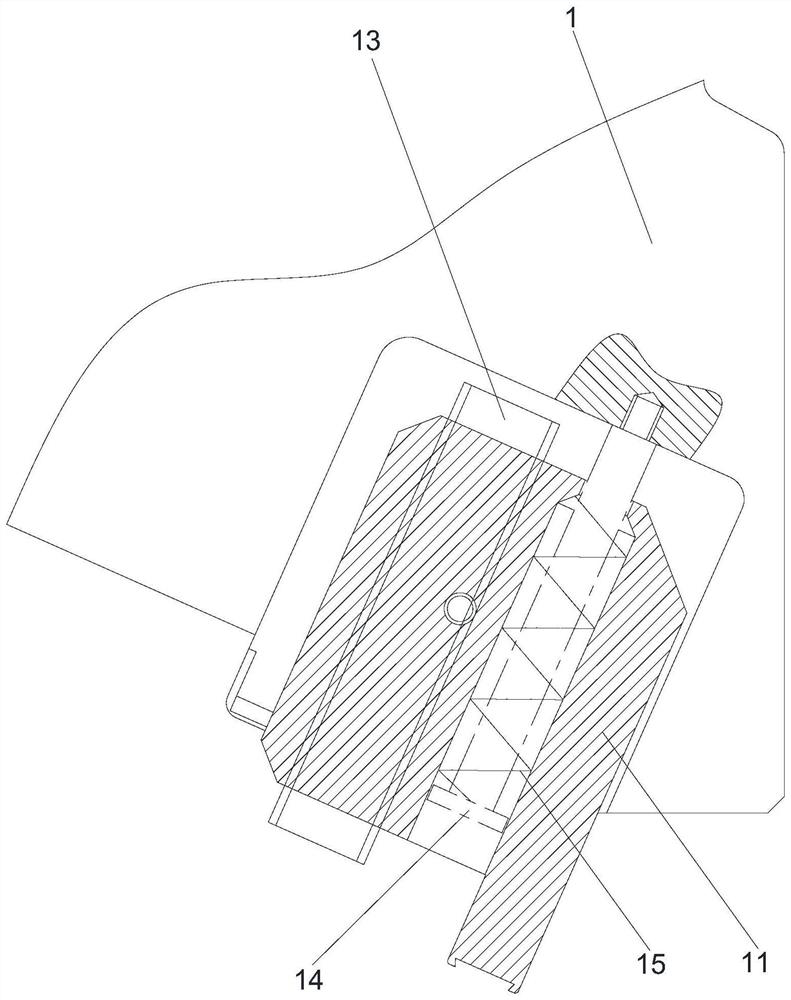

[0036] Such as Figure 1-Figure 9 As shown, a bonding mechanism for a foam bonding device for a touch screen includes a bonding fixing plate 1, a feeding swing arm 2, a feeding drive device 3, a pressing assembly 4, a cutting assembly 100, and a mutual cooperation The first slider 5 and the second slider 6; as figure 1 As shown, the feeding driving device 3 is installed on one end surface of the fixed plate 1 and the output shaft of the feeding driving device 3 is hinged with the middle or rear end of the feeding swing arm 2 through the first slider 51, and the first slider 5 is inclined Ground and slidably installed on the fixed plate 1 through a first slide rail assembly 51. In this embodiment, the output shaft of the feeding drive device 3 is hing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com