Force-controlled electric hand

An electric motor and direct motion technology, which is applied in the direction of program control of manipulators, electric components, and control of mechanical energy, can solve problems such as difficult to detect gripping force, swelling, and changes with good accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

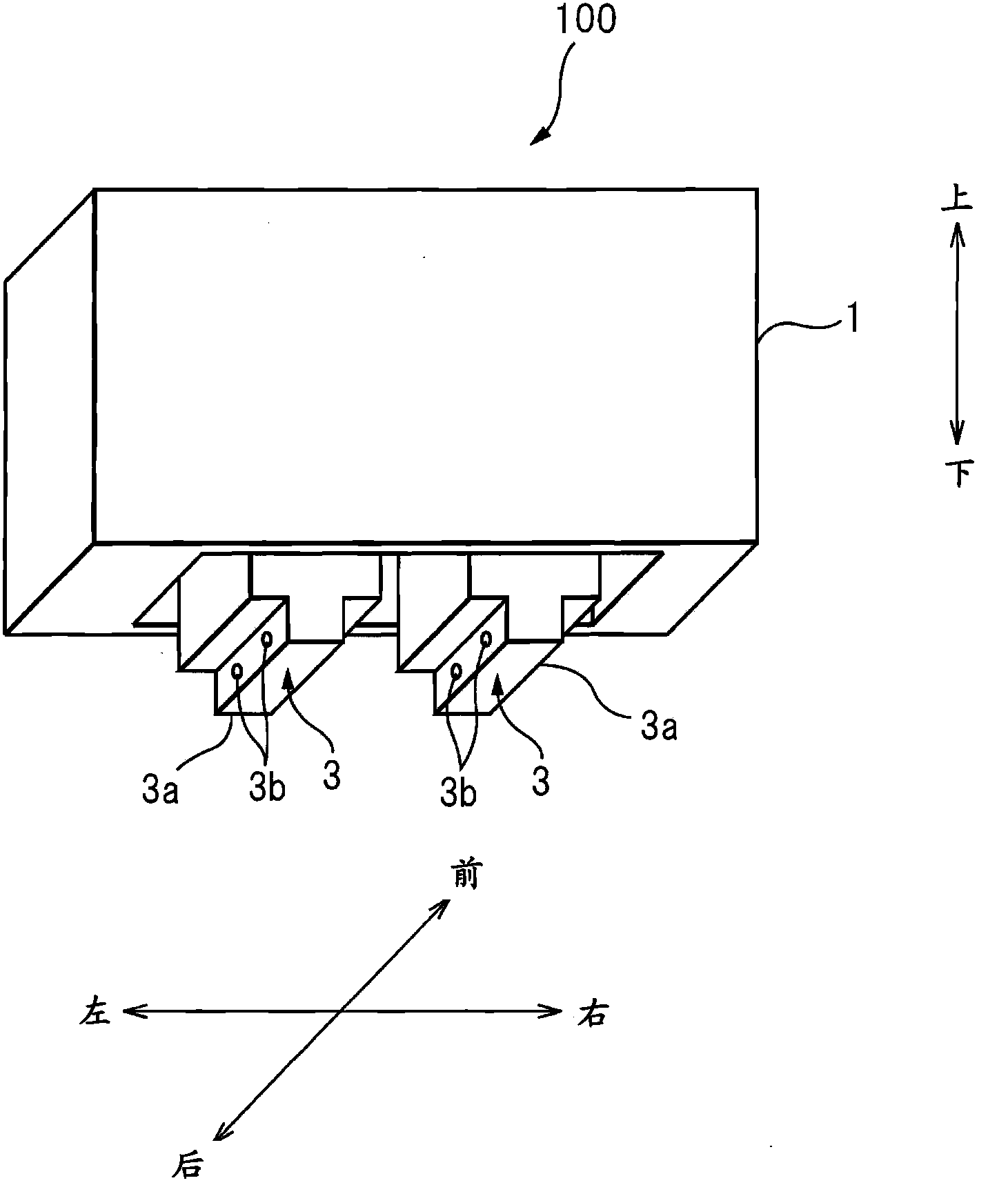

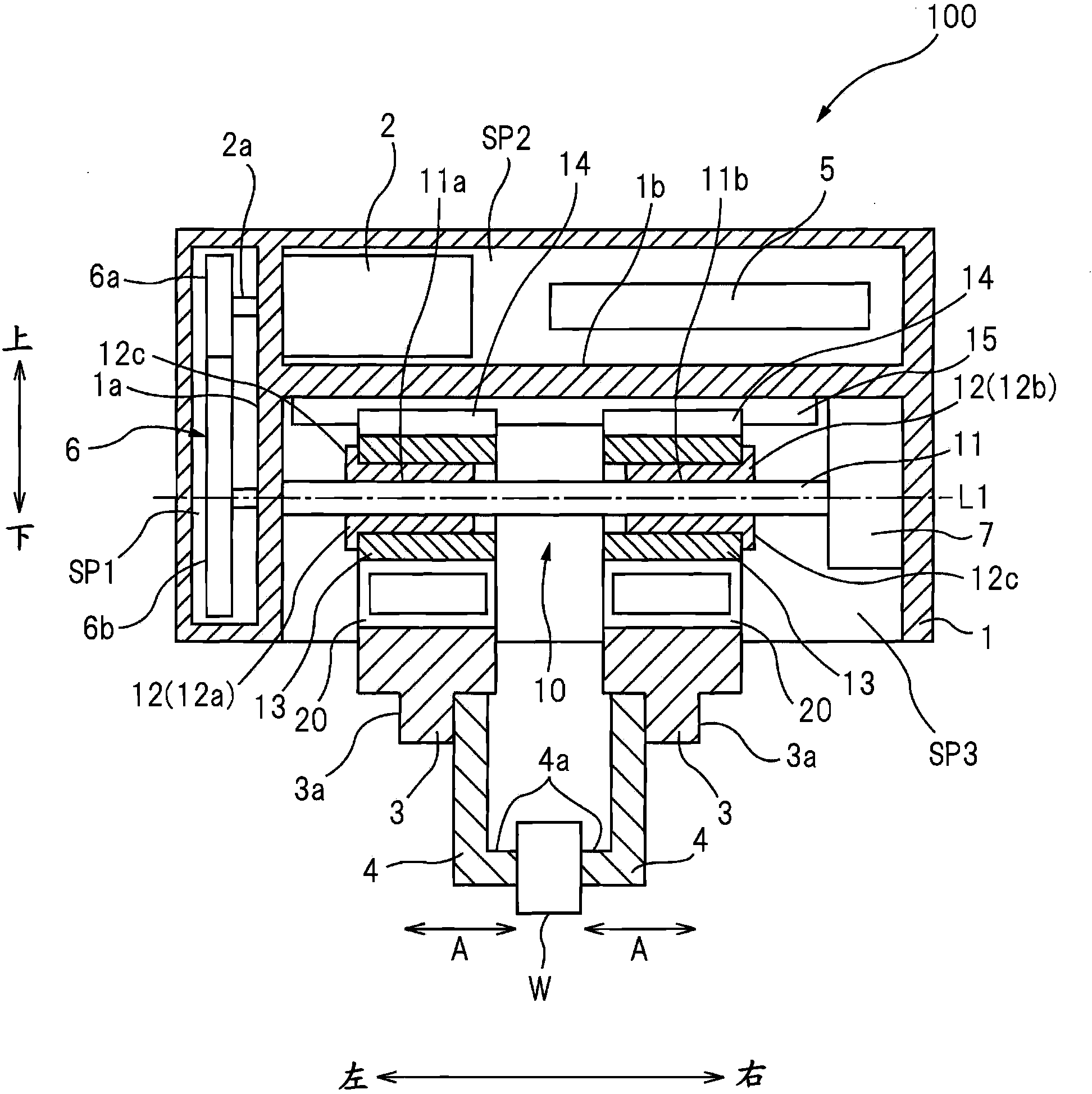

[0013] Below, refer to Figure 1 ~ Figure 3 A first embodiment of the present invention will be described. figure 1 It is a perspective view showing the overall structure of a force control electric hand 100 (hereinafter, may be simply referred to as an electric hand) according to the first embodiment of the present invention. This electric hand 100 is attached to, for example, an arm tip of an industrial robot to grasp an object to be grasped (hereinafter, sometimes simply referred to as an object), and has a pair of fingers that can be opened and closed (refer to figure 2 ),but figure 1 Its illustration is omitted.

[0014] In addition, in the following, for the convenience of description, three mutually orthogonal directions shown in the drawings are defined as the front-rear direction, the left-right direction, and the up-down direction, and the configuration of each part will be described based on these definitions. The left-right direction is a direction in which a p...

no. 2 approach

[0046] refer to Figure 4 A second embodiment of the present invention will be described. The aspect in which the second embodiment differs from the first embodiment in particular lies in the structure of the finger base 3 . That is, in the first embodiment, the pair of finger bases 3 are configured to be movable in the left and right directions as movable finger bases, but in the second embodiment, only the pair of finger bases 3 A composition of is able to move. Such an electric hand 100 is called a single-opening hand.

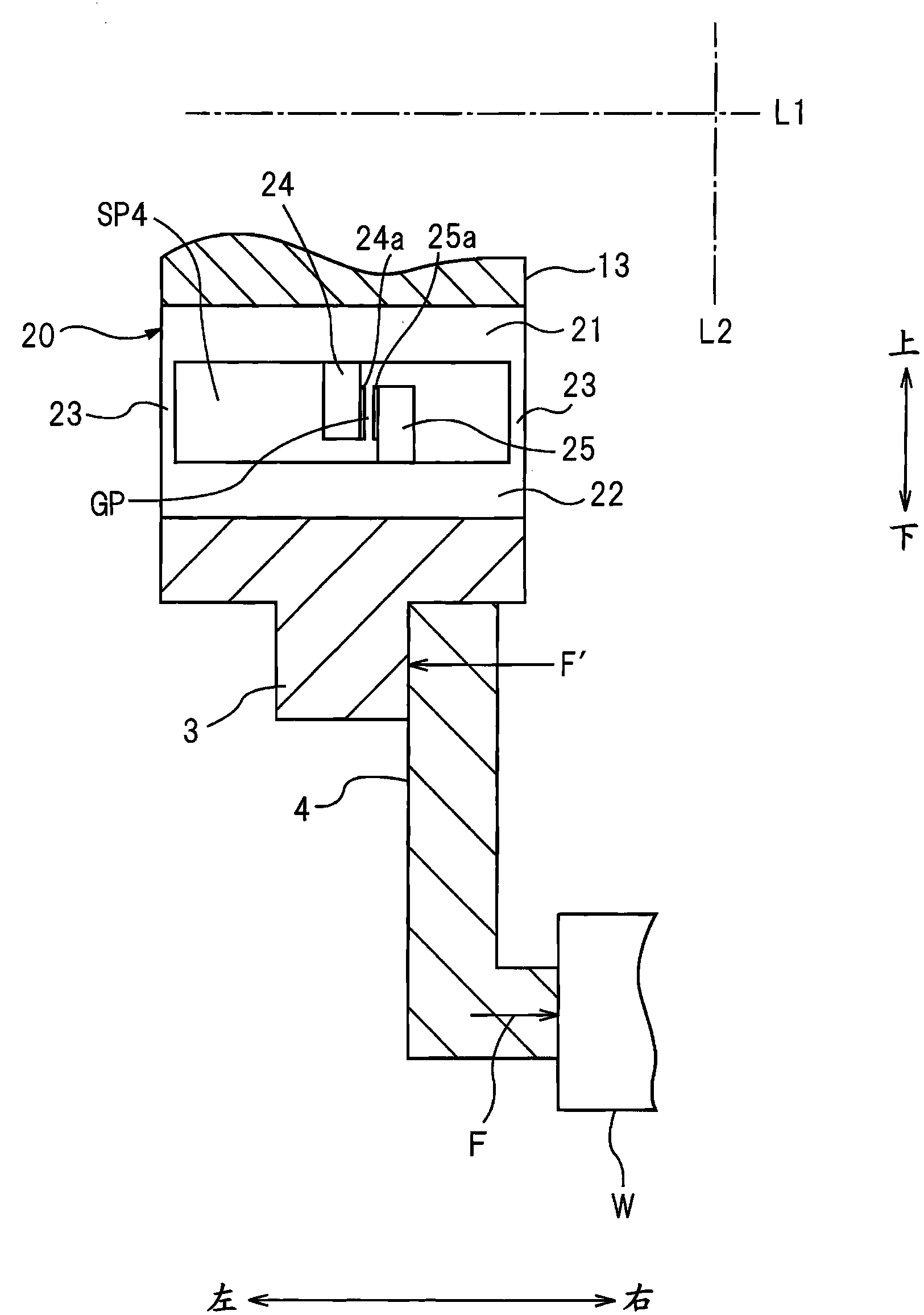

[0047] Figure 4 It is a sectional view showing the structure of main parts of the electric hand 100 of the second embodiment. Additionally, for figure 2 The same parts are given the same symbols, and the points different from the first embodiment will be mainly described below. Such as Figure 4 As shown, among the pair of left and right force sensors 20 , the right force sensor 20 is fixed to the lower surface of the rotation detector 7 . Therefore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com