Tablet press guide rod upper punch mechanism

A technology of tablet presses and guide rods, which is applied to punching machines, presses, manufacturing tools, etc., can solve the problems that the product is not compact enough, cannot accurately guarantee the holding time and effect of holding pressure, and achieve good transmission and increase pressure, ensure the effect of holding pressure, and ensure the effect of holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

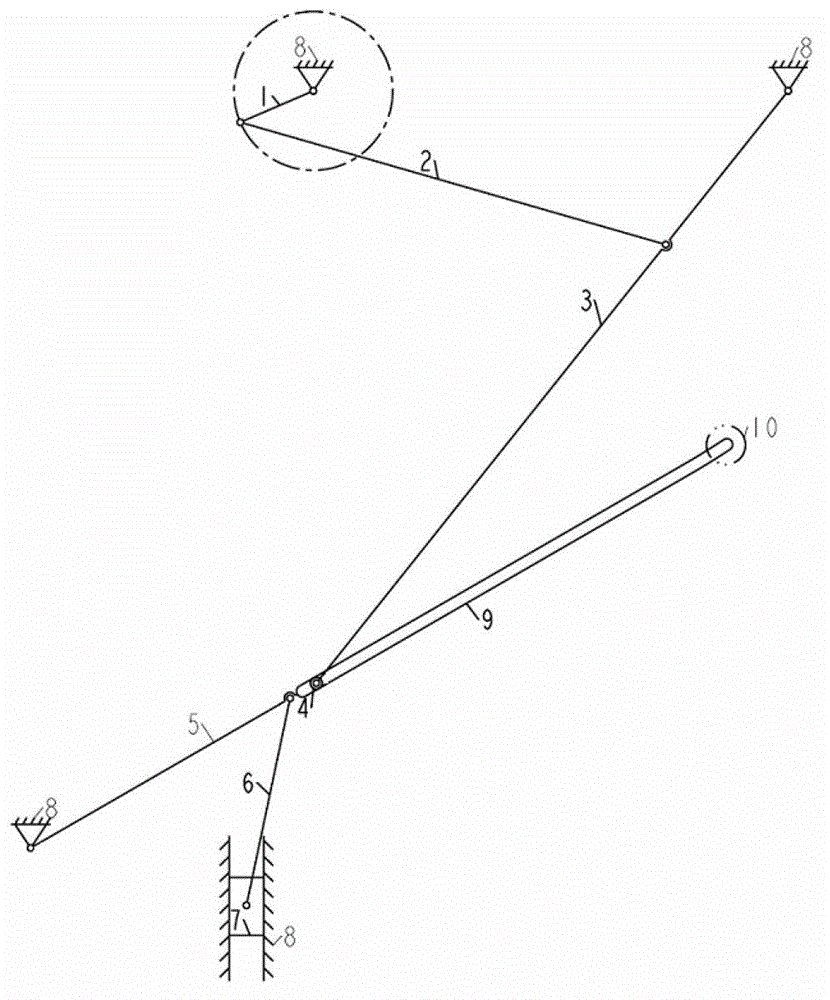

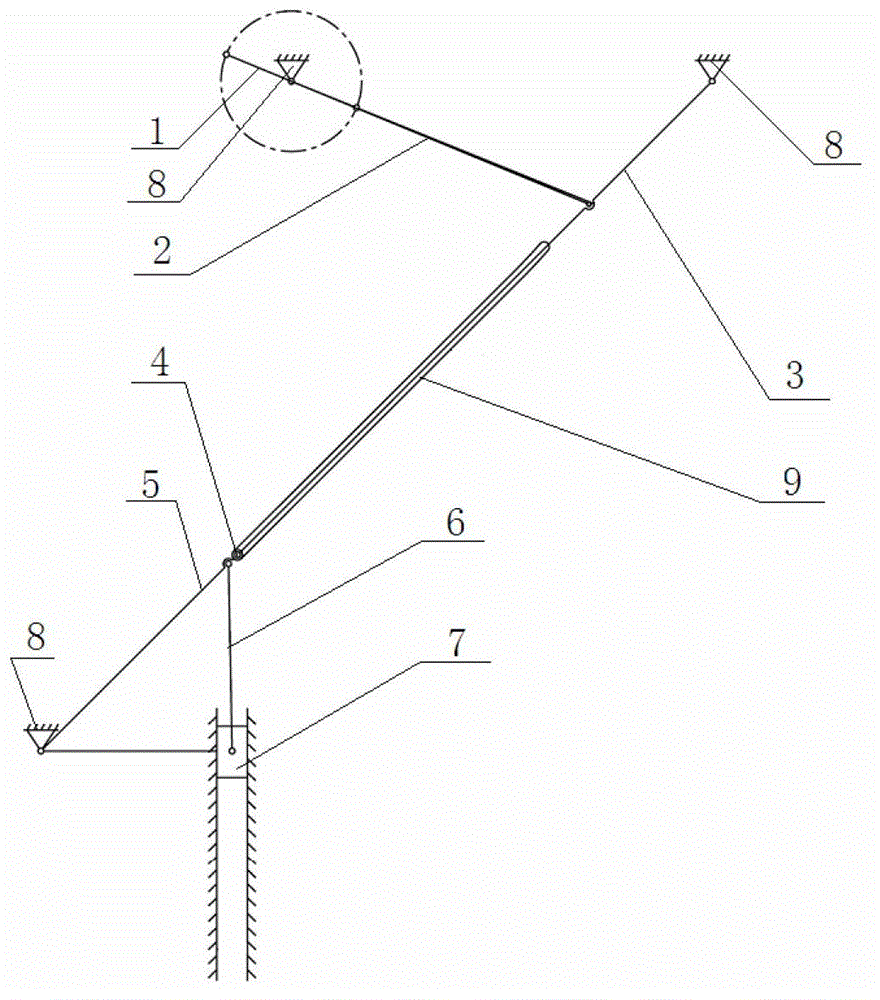

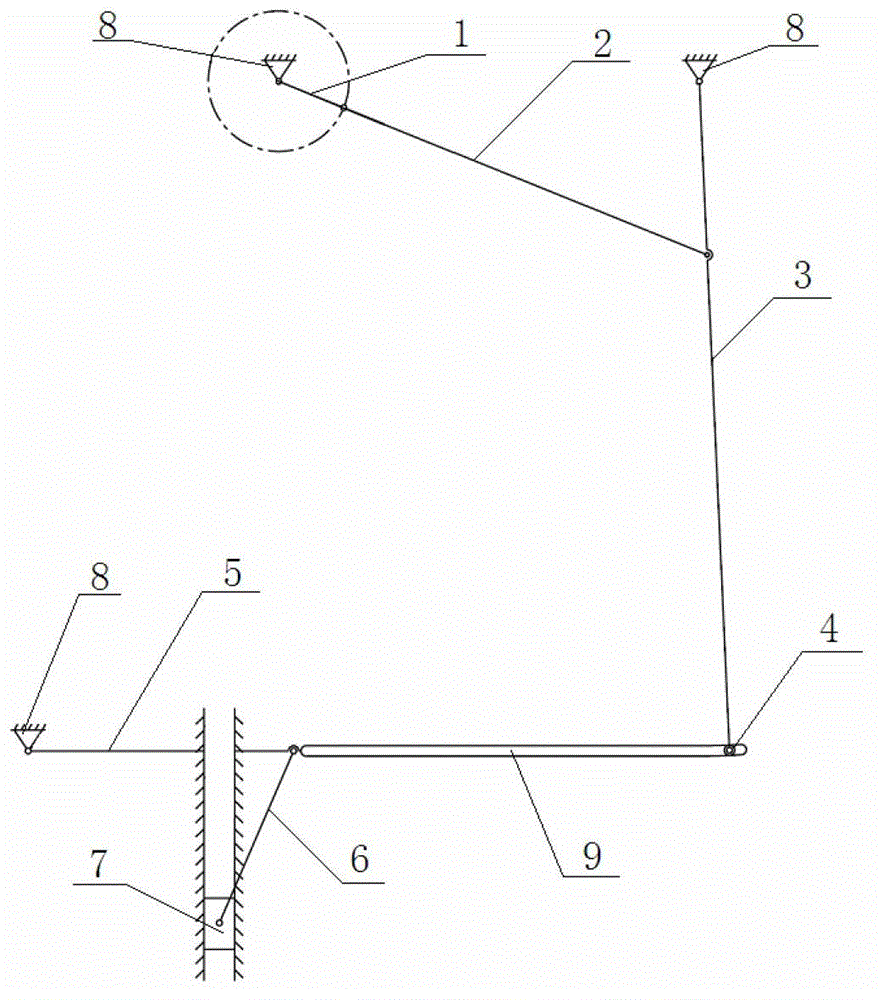

[0024] A punch mechanism on a guide rod of a tablet press, the structure is as follows figure 1 As shown, the mechanism includes a crank-rocker mechanism, a roller 4 and a guide rod mechanism; the crank-rocker mechanism includes a crank 1, a first connecting rod 2 and a rocker 3, one end of the crank 1 is rotatably connected to the frame 8, and the first The two ends of a connecting rod 2 are respectively connected to the other end of the crank 1 and the middle of the rocker 3 in rotation. The mechanism includes a guide rod 5, a second connecting rod 6 and an upper punch 7. One end of the guide rod 5 is rotatably connected to the frame 8. The guide rod 5 is provided with a slideway 9, and the slideway 9 is connected with the roller 4 high pair. (The roller 4 and the slideway 9 in the guide rod 5 form a cam high pair), one end of the second connecting rod 6 is rotatably connected to the middle of the guide rod 5, and the other end is rotatably connected to the upper punch 7.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com