Sheet material crawling prevention device

A thin sheet and meandering technology, which is applied in the field of meandering prevention devices for sheet materials, can solve problems such as position deviation and damage, and achieve the effect of preventing meandering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

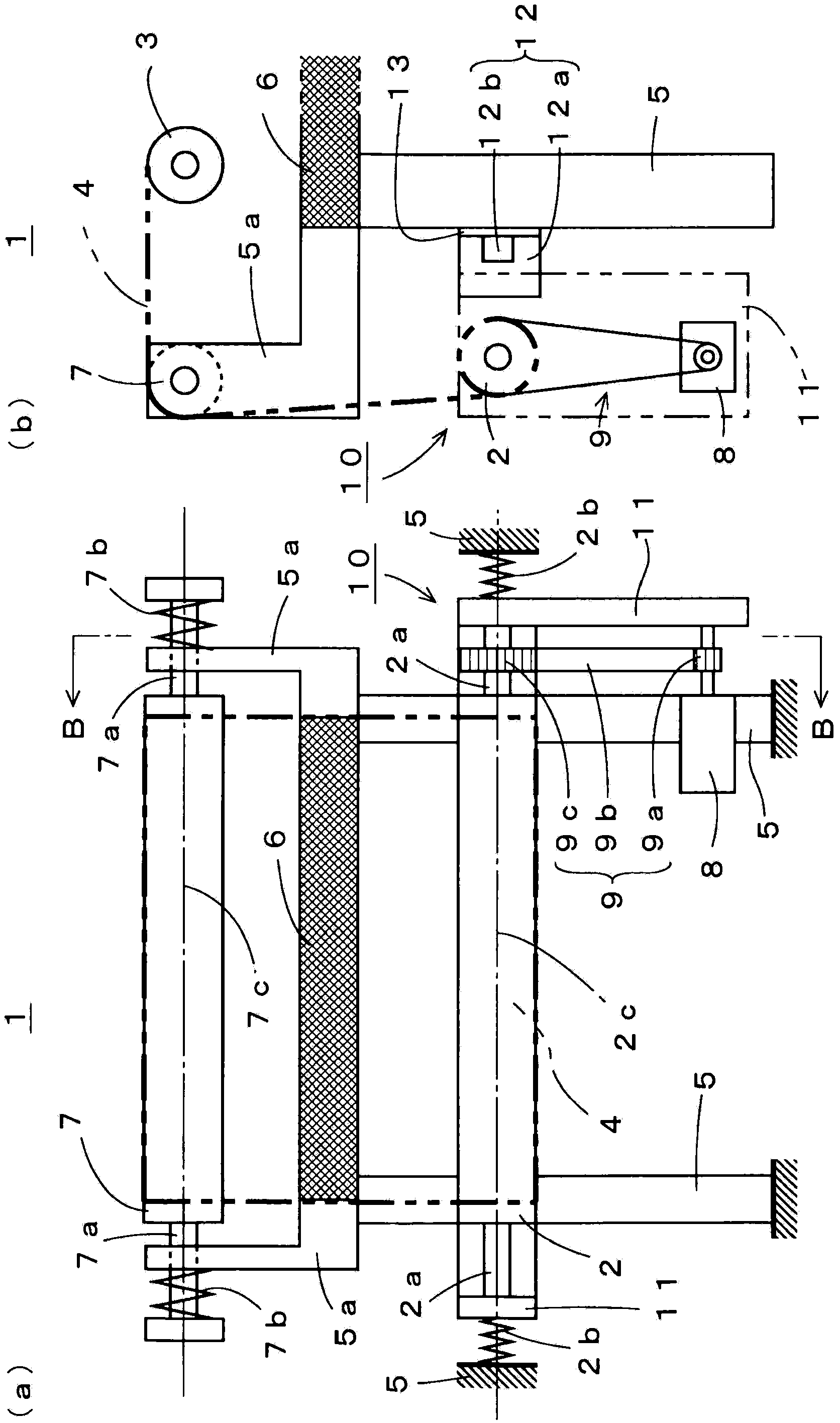

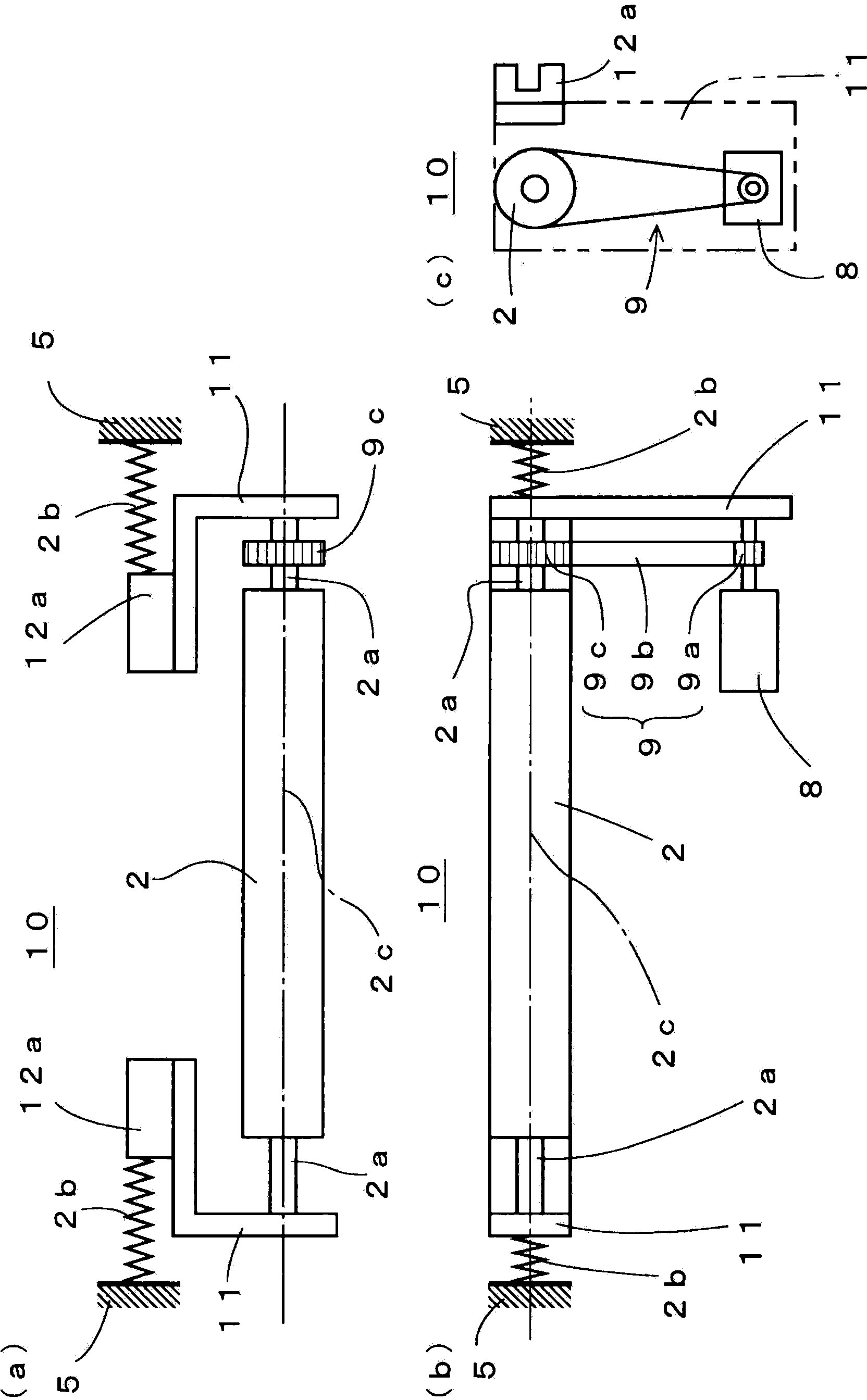

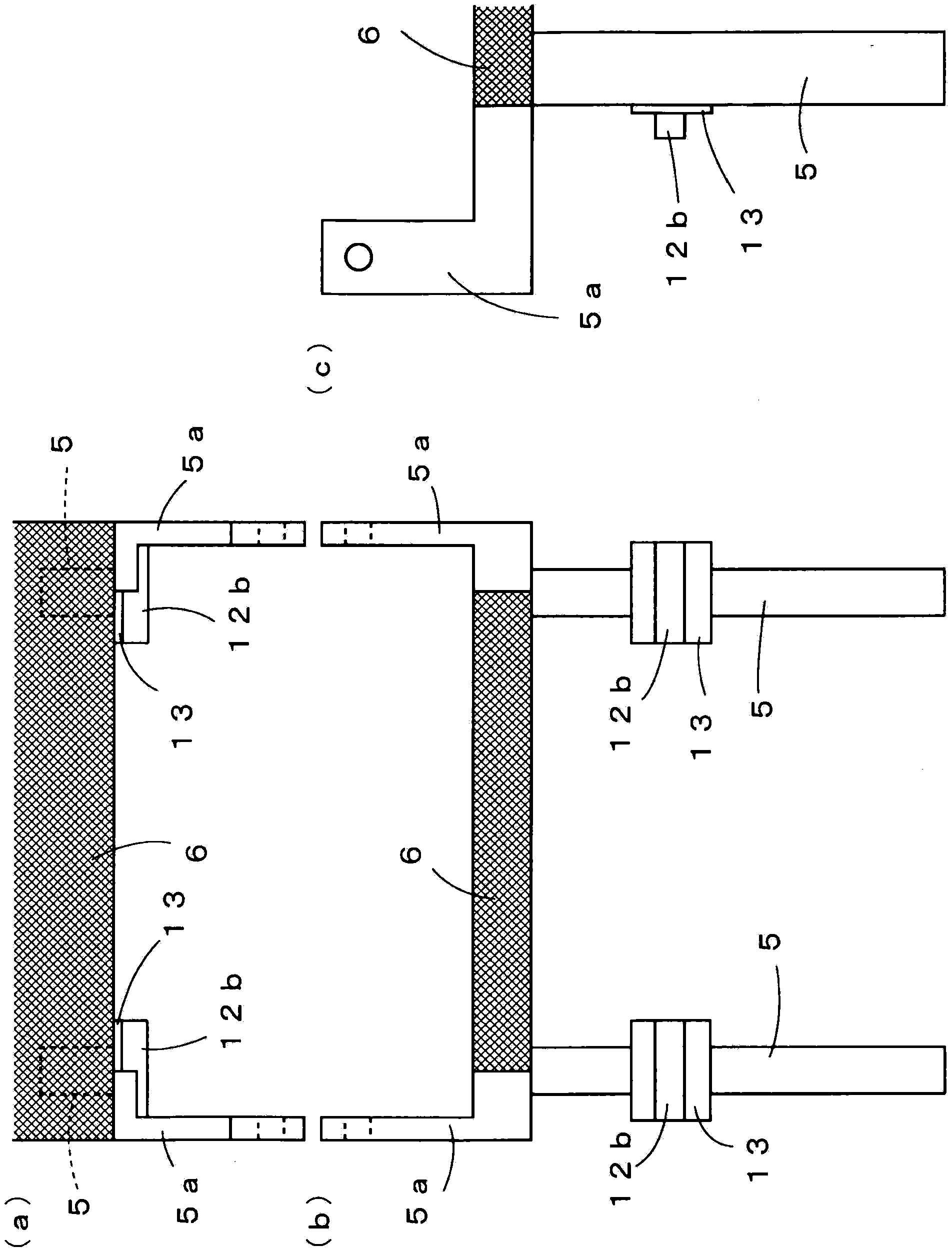

[0037] figure 1 The schematic structure of the meandering prevention apparatus 1 of a sheet material which is one Example of this invention is shown schematically. figure 1 (a) shows the structure seen from the front, figure 1 (b) means from figure 1 (a) Structure seen by section line B-B.

[0038] The meandering preventing device 1 of a sheet material includes a winding roller 2 and a feeding roller 3 . The sheet material 4 moves between the winding roller 2 and the pay-out roller 3 . The direction in which the sheet material 4 moves can be switched between the direction from the delivery roller 3 to the winding roller 2 and the direction from the winding roller 2 to the delivery roller 3, and can also be reciprocated multiple times by repeated switching. The sheet material meandering preventing device 1 prevents meandering when the sheet material 4 moving in the direction from the delivery roller 3 to the winding roller 2 is wound up by the winding roller 2 .

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com