Shipping system and method for wide and thick plates

A technology of wide and thick plates and telescopic devices, which is applied in the field of transportation systems, can solve problems such as failure of permanent magnetic sucker spreaders, quality problems, and low work efficiency, so as to reduce the incidence of spreader failures, ensure accurate judgments, and improve lifting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

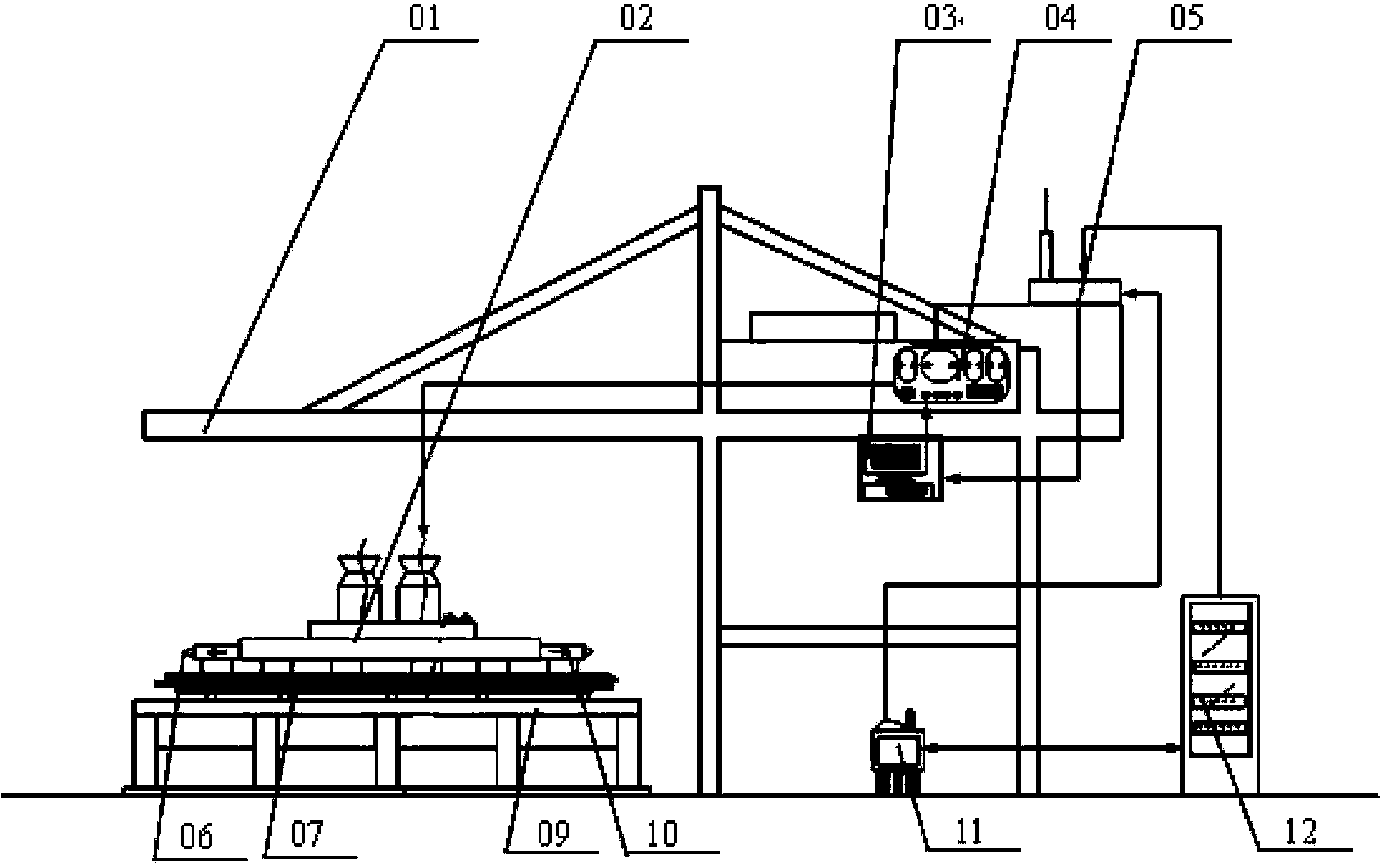

[0048] Such as figure 2 As shown, in this embodiment, the wide and thick plate shipping system includes: a spreader 01 for lifting the wide and thick plate 07, the spreader 01 is provided with a permanent magnetic sucker 02, and the permanent magnetic sucker 02 has a sucker telescopic device 10, the sucker The retractable device 10 can adjust the size of the permanent magnetic chuck 02 according to the length of the wide and thick plate 07; the wide and thick plate 07 has a barcode identifying the identity and specification information of the wide and thick plate; the barcode reader on the handheld wireless terminal 11 reads the barcode, and the hand-held The wireless terminal 11 is connected with the server 12, and downloads the identity and specification information of a batch of wide and thick plates from the server 12 before starting shipment; The identity and specification information of the wide and thick plate of the handheld wireless terminal 11; PLC04 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com