Ball-type circulating bioreactor

A bioreactor and reactor technology, applied in biological sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of incompatibility of sludge biological drying reactors, and achieve outstanding advantages, efficient utilization, System compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

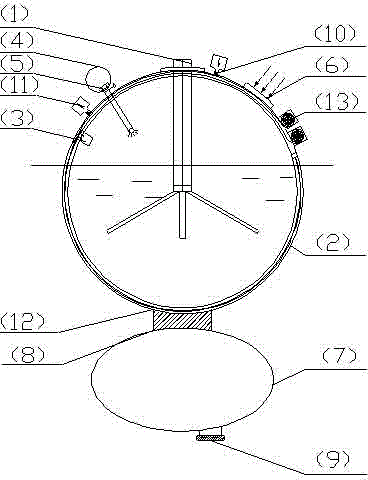

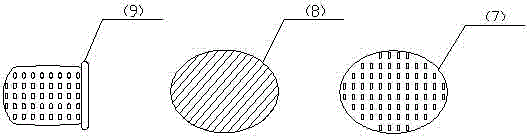

[0025] The circulating bioreactor is a spherical reactor with an upper and lower structure, wherein the feeding port, the microbial input device and the air supply equipment are all installed in the upper half of the spherical reactor, and a double-rod stirrer is installed in the middle of the upper hemisphere of the reactor. There is an ellipsoidal filtrate (sludge) recovery tank connected under the device, which is responsible for the boring recovery and circulation during the reaction; the specific working process is: after feeding the materials that have been fully mixed with auxiliary materials from the feeding port 6, open the pressurized strain tank 4 and the metering pump 5 start the double-rod agitator 1 after putting in the microbial preparation, so that the materials are mixed evenly, and the wall surface of the closed box is guaranteed to be at a constant temperature of 55°C due to the action of the water bath; at the same time, the prefabricated fans 10 and 11 are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com