A kind of equipment of producing dimethyl sulfate

A dimethyl sulfate and equipment technology, applied in the field of equipment for the production of dimethyl sulfate, can solve the problems of restricting enterprise innovation and progress, low safety and environmental protection coefficient, low reaction efficiency, etc., to achieve long-term contact, increase production capacity and Product quality, the effect of improving the esterification reaction rate and esterification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technology, features, purposes and effects of the present invention easier to understand and understand, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention, but the present invention is not limited thereto.

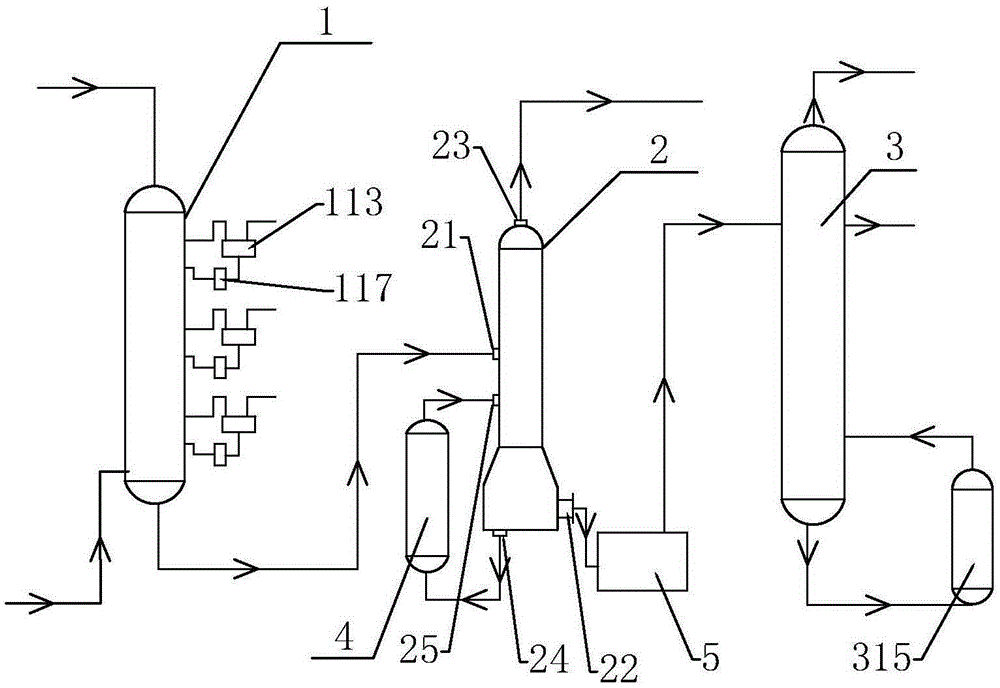

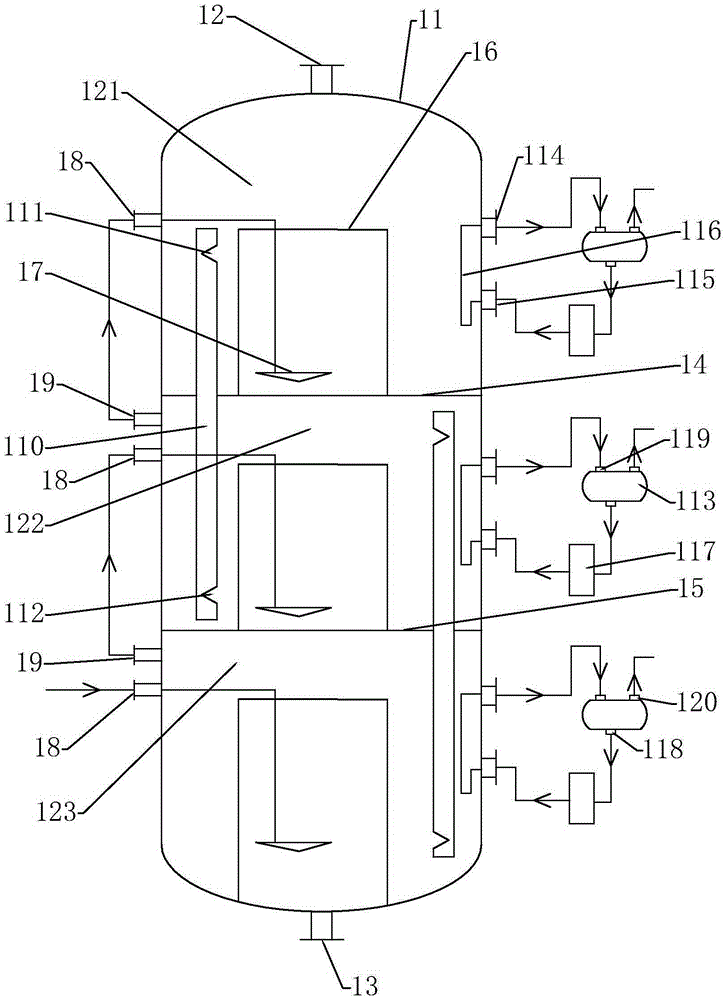

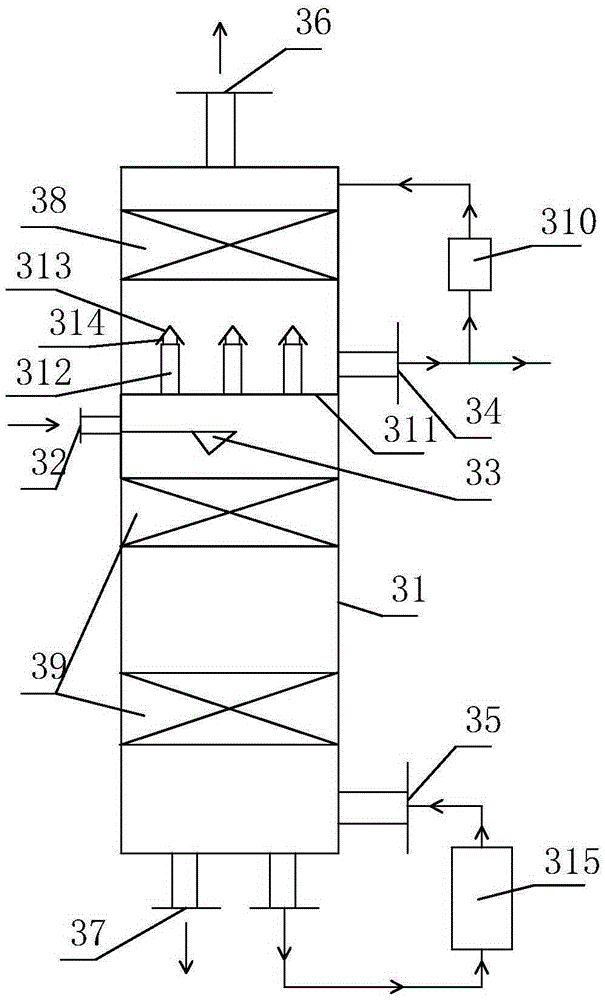

[0019] Such as Figure 1-Figure 4 Shown in, this embodiment comprises esterification reaction tower 1, degassing tower 2 and rectifying tower 3, and the top feed inlet 12 of esterification reaction tower 1 top is connected with liquid material source by pipeline, and esterification reaction tower 1 The esterification reaction tower material outlet 13 at the bottom communicates with the degassing tower feed port 21 in the middle part of the degassing tower 2 through a pipeline, and the degassing tower outlet 22 on one side of the bottom of the degassing tower 2 passes through a pipeline through a material pump 5 and The feed port 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com