Resin composition for optical material and method for production thereof

A technology of resin composition and optical materials, applied in the field of optical materials, can solve the problems of small retardation and unusability, and achieve the effects of small retardation, excellent transparency and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0133] 100 parts by weight of SUMIPEX (registered trademark) MHF and 3.1 parts by weight of SD2201W were dry-blended with a kneader (manufactured by Nippon Steel Works, Ltd., TEX-30) at 250°C and 200rpm By kneading, a resin composition is obtained.

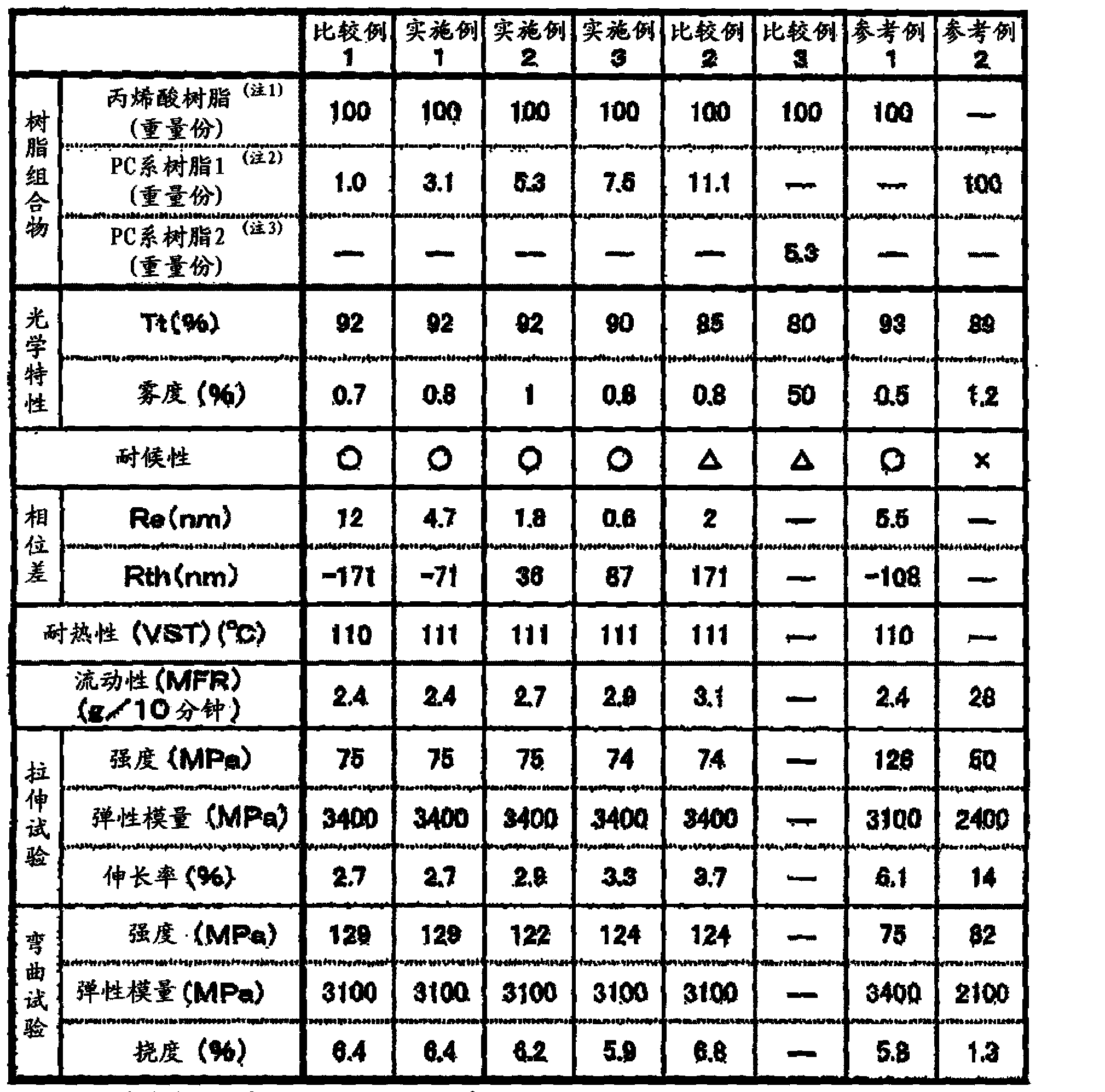

[0134] The obtained resin composition was injection molded at 250° C. using an injection molding machine (manufactured by Toshiba Machine Co., Ltd., IS-130) to obtain a molded body (optical material) having a thickness of 3 mm. The above-mentioned physical properties (total light transmittance, haze, weather resistance, birefringence, heat resistance, fluidity, and mechanical properties) were measured for the obtained molded body. The results are shown in Table 1.

Embodiment 2、3 and comparative example 1~3)

[0136] Except having used the resin described in Table 1 at the ratio described in Table 1, the resin composition was obtained by the procedure similar to Example 1, respectively.

[0137] A molded body having a thickness of 3 mm was obtained in the same procedure as in Example 1 except that the obtained resin composition was used. The above-mentioned physical properties were measured for each of the obtained molded articles. The results are shown in Table 1.

reference example 1)

[0139] A molded body having a thickness of 3 mm was obtained in the same procedure as in Example 1 except that an acrylic resin (SUMIPEX (registered trademark) MHF) was used alone instead of the resin composition obtained in Example 1. The above physical properties were measured for the obtained molded body. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com