Plug-in type combined curtain wall

A plug-in, curtain wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problem of unsafe curtain wall structure, and achieve the effect of reducing the types of molds, improving reliability and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

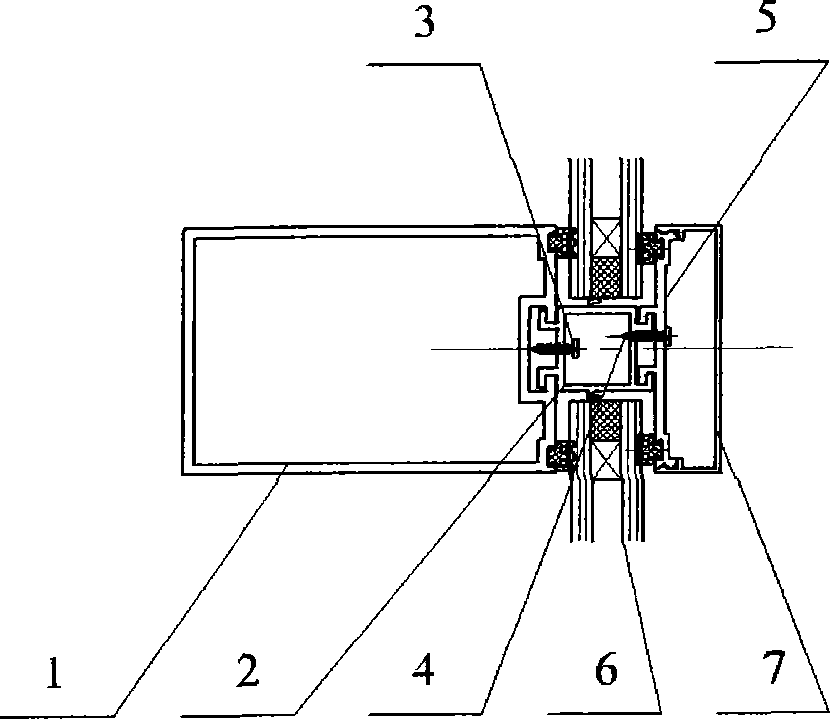

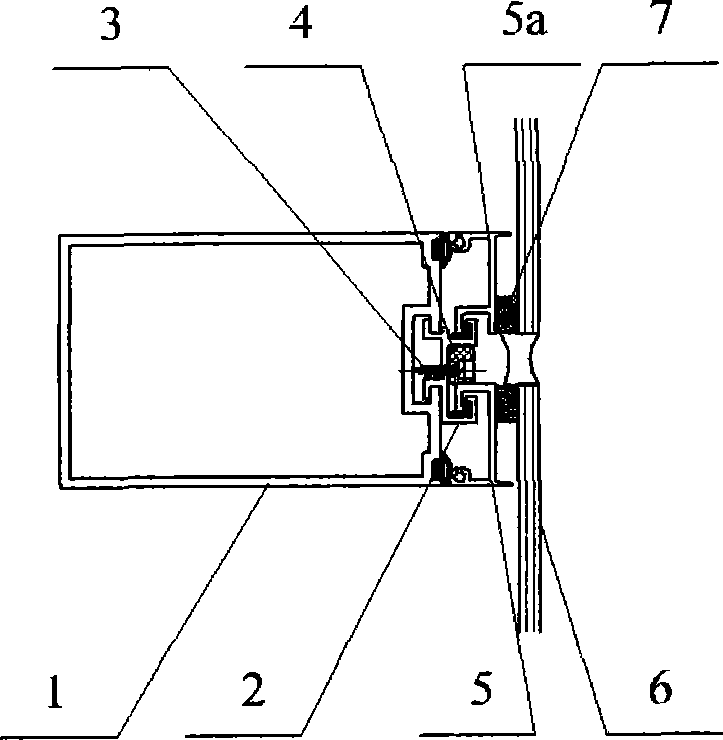

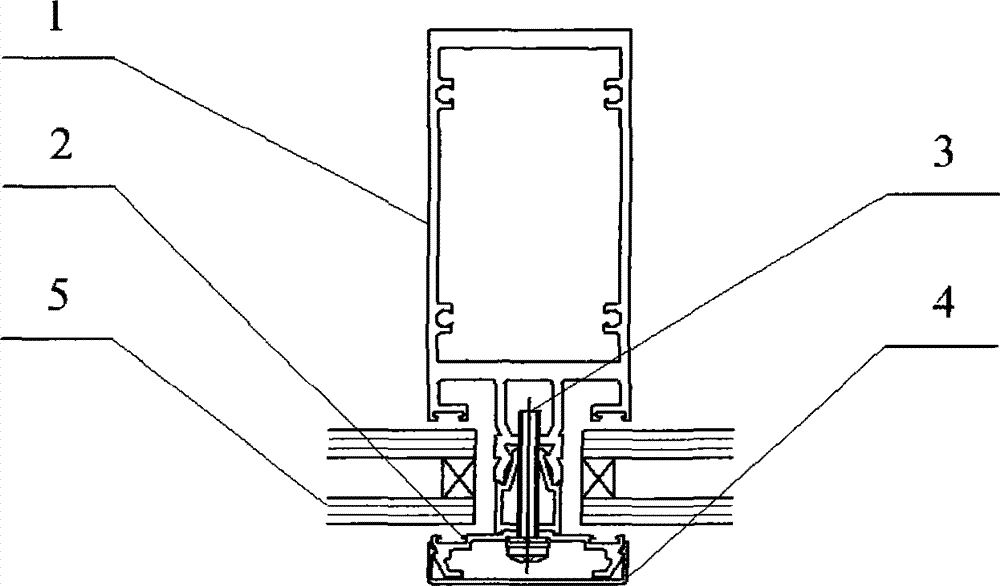

[0022] Depend on figure 1 , figure 2 It can be seen that the connection groove designed for the column (or beam) 1 of the plug-in composite curtain wall has a standardized uniform size, and it is compatible with the exposed frame connector 2 ( figure 1 ) can be combined into the main frame of the exposed frame curtain wall; and the hidden frame connector 2 ( figure 2 ) on the corresponding standardized uniform-sized tenon fit connection, which can be combined into the main frame of the hidden frame curtain wall. Using set screw 3 ( figure 1 , figure 2 ) can prevent the relative sliding displacement between the two profiles. Therefore, the column (or beam) 1 of the plug-in composite curtain wall can be standardized and interchanged, and can be used for both the exposed frame curtain wall and the hidden frame curtain wall. The force connection of the plug-in com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com