Oil pan structure of engine

A technology of oil pan and engine, which is applied in the direction of engine lubrication, engine components, machines/engines, etc. It can solve problems such as the temperature rise of lubricating oil, the difficulty of removing the oil plug inside the oil drain plug, and the complicated structure of the oil drain plug. , to achieve the effect of suppressing the decline of lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

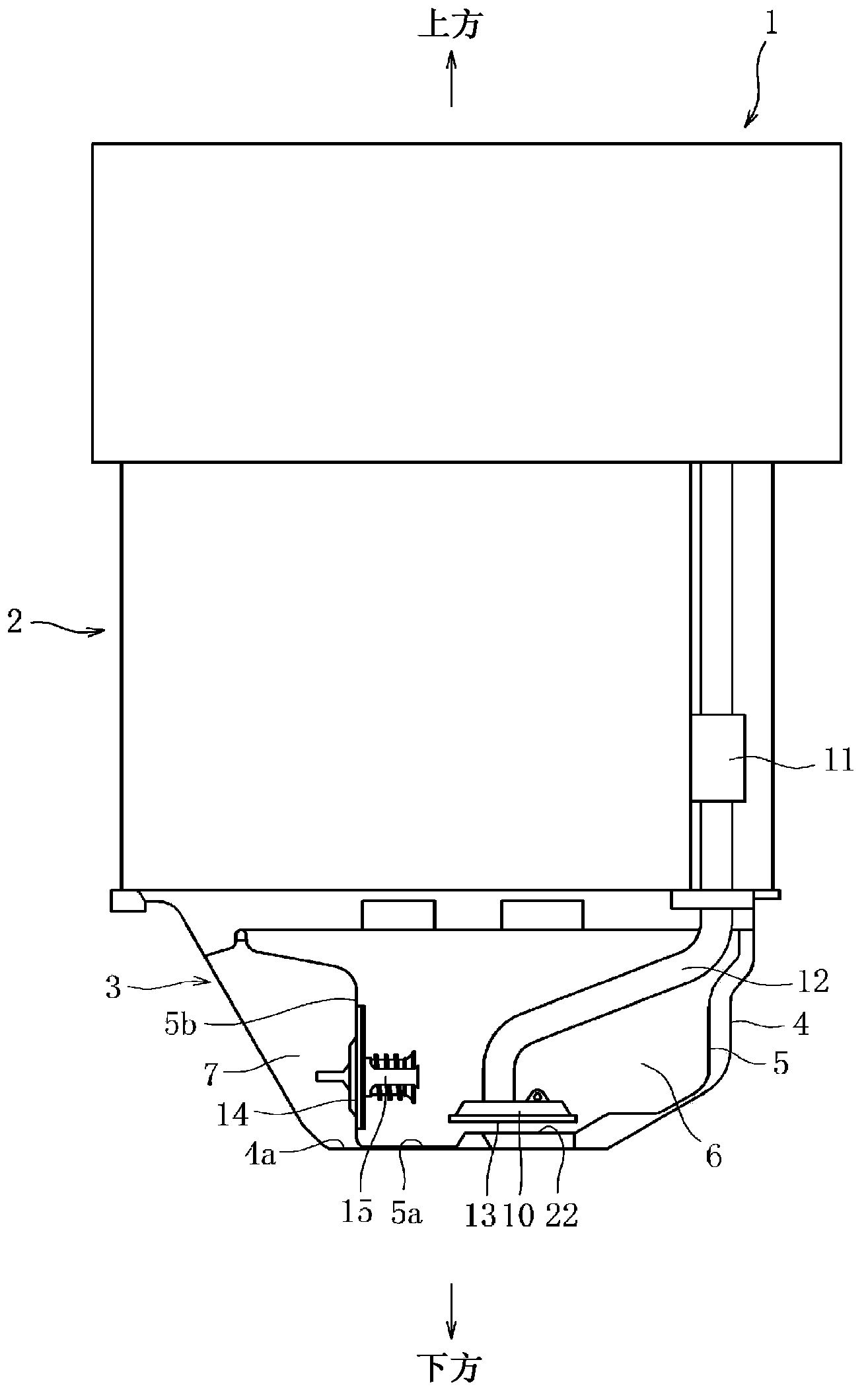

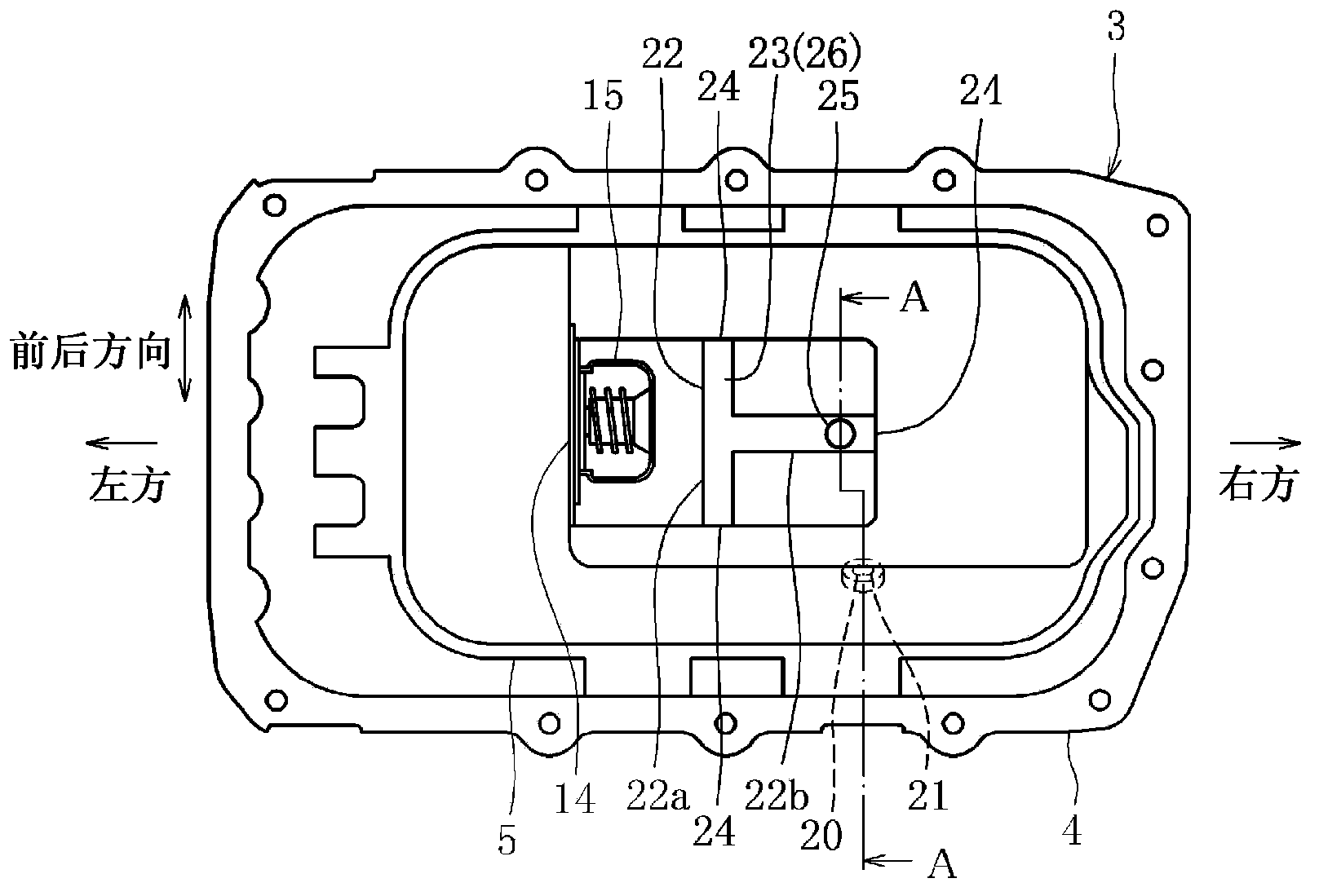

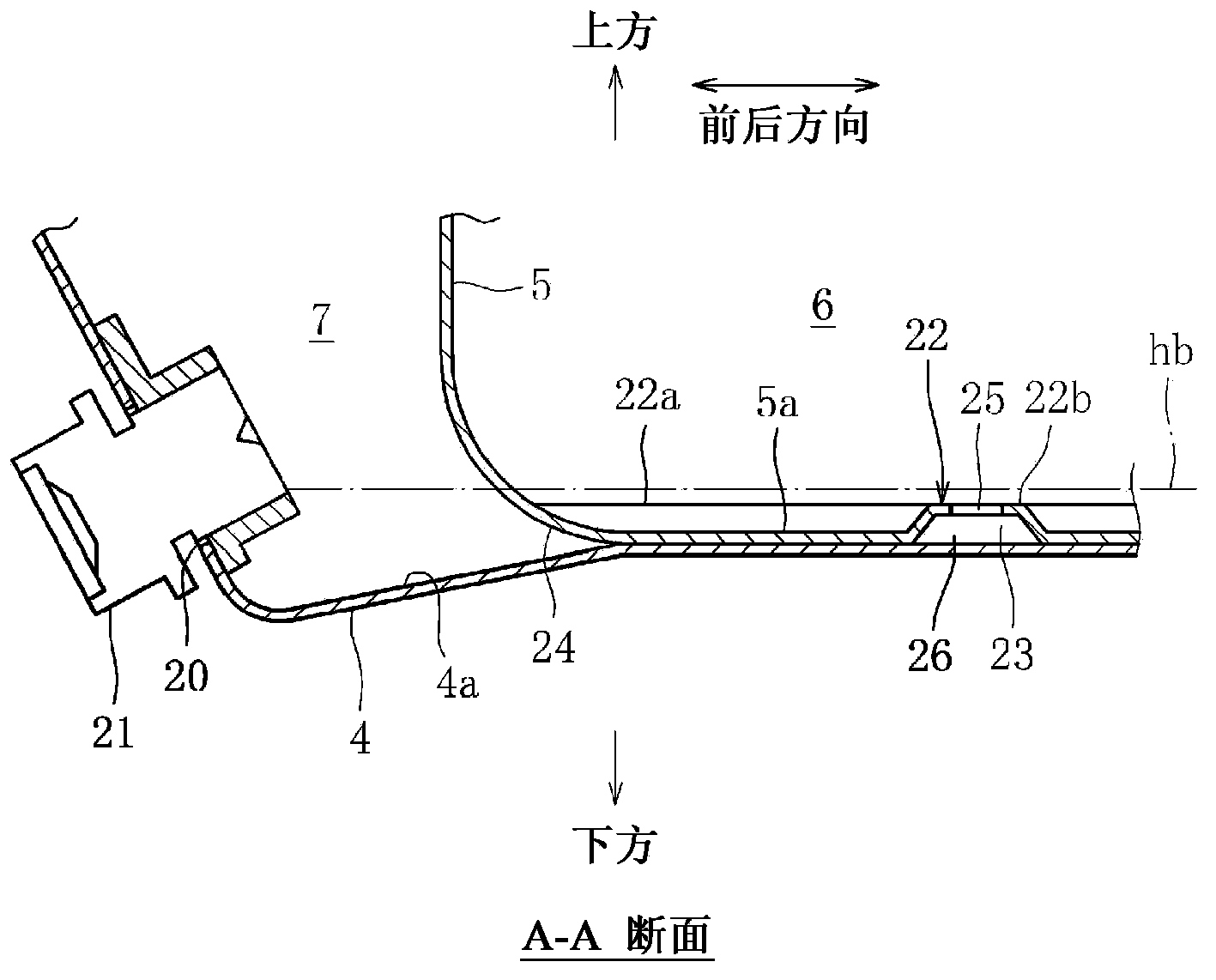

[0027] Below, will be based on Figure 1 to Figure 4 The illustrated embodiments illustrate the invention. figure 1 It is a vertical cross-sectional view showing an outline of the structure of the engine 1 according to the present embodiment employing the oil pan structure of the present invention. In the lower portion of the cylinder block 2 of the engine 1 according to the present embodiment, an oil pan 3 for storing lubricating oil is provided.

[0028] The oil pan 3 is an oil pan 3 having a double structure composed of an outer oil pan 4 and an inner oil pan 5 with an upper opening having a substantially rectangular shape.

[0029] The inner oil pan 5 is smaller than the outer oil pan 4, is disposed in the outer oil pan 4, and has a first storage chamber 6 inside which lubricating oil can be stored.

[0030] The bottom of the inner oil pan 5 is placed on the bottom wall 4a of the outer oil pan 4, and partly connected. The inner oil pan 5 is formed laterally smaller than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com