Offset press varnish printing device

A technology of a printing device and an offset printing machine, which is applied in the directions of printing, printing machine, printing process, etc., can solve the problems of reducing work efficiency, working environment pollution, increasing workload, etc., so as to improve work efficiency, reduce workload, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

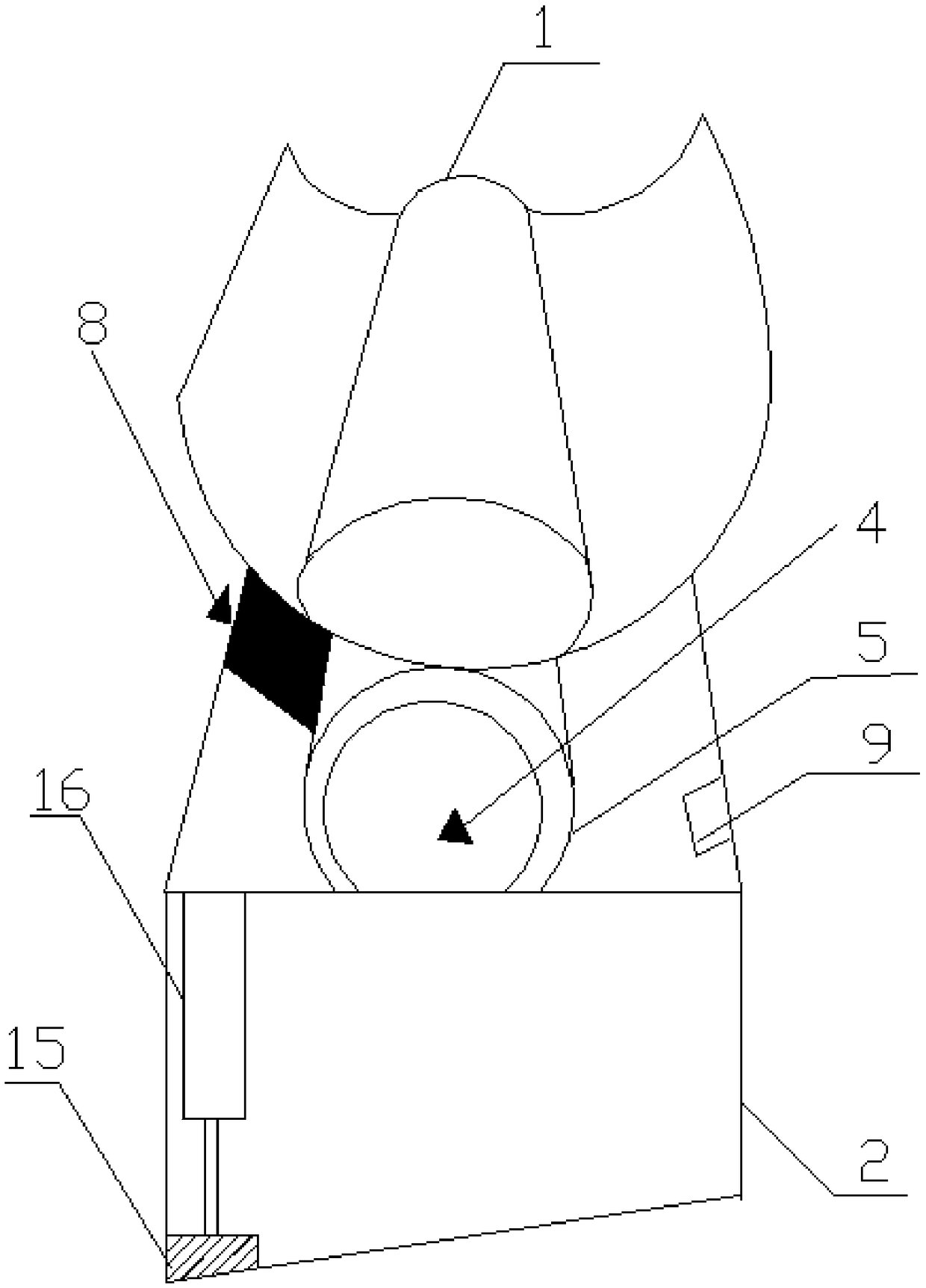

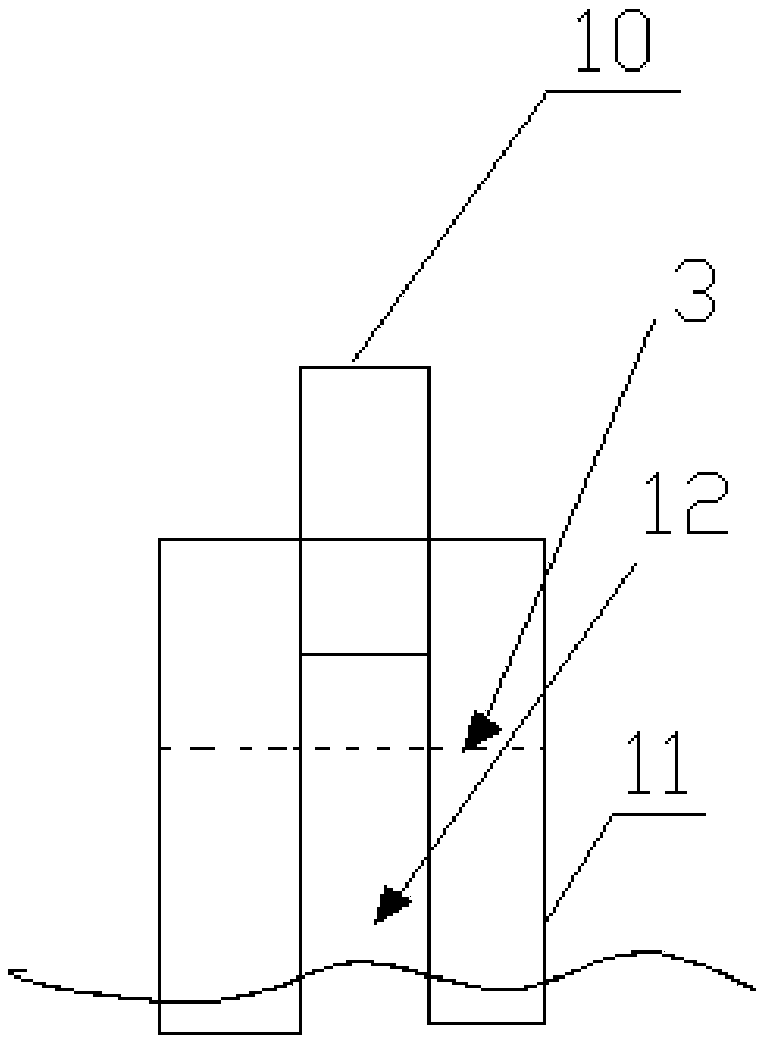

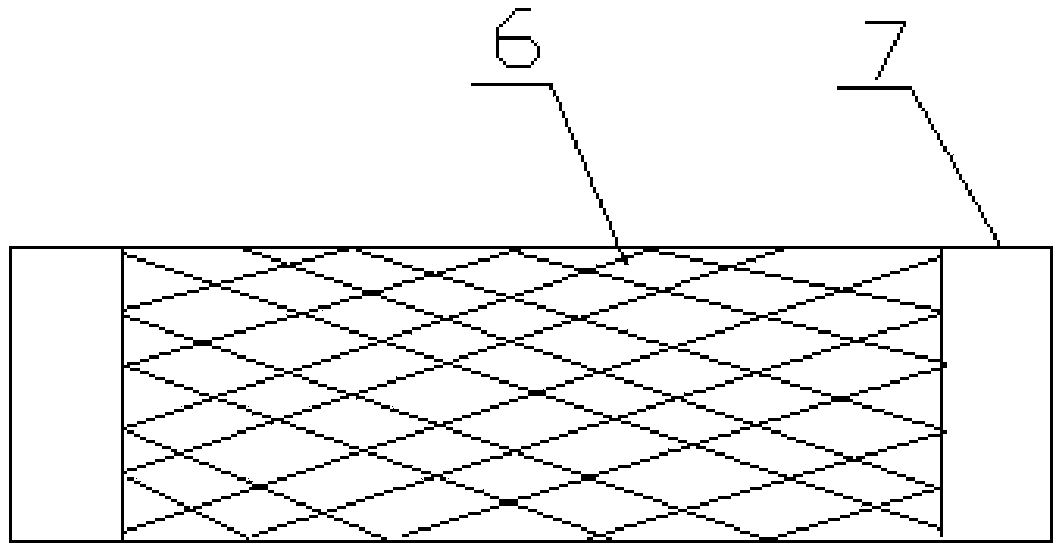

[0027] Such as figure 1 , 2 , 3, and 4, a varnish printing device for an offset printing machine includes an impression cylinder 1 for embossing paper, an offset printing mechanism for printing paper with the impression cylinder 1, and an offset printing mechanism arranged below the offset printing mechanism. The oil receiving tank 2 for receiving ink is provided with an oil discharge port for discharging the ink when the ink liquid level in the oil receiving tank 2 reaches the liquid level warning zone 3 on the oil receiving tank 2, and the oil discharge port is provided with a sealing plate 15. The structure is simple and easy to discharge oil. There is a telescopic cylinder 16 on the sealing plate to control the expansion and contraction of the sealing plate. The sensing element sends a signal to the controller, and the controller sends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com