Friction coupler friction block

A friction block and coupling technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of damaged friction block a5, failure to achieve functional effects, etc., and achieve the effect of simple structure and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

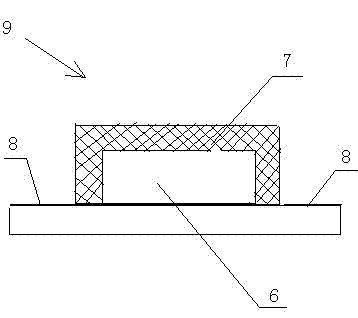

[0012] Such as figure 2 As shown, the friction block friction block b9 of the friction coupling is composed of a skeleton body 6, a coating 7 and a boss 8; the skeleton body 6 and the bosses 8 on both sides are made of metal material, and are integrally formed; the coating 7 is coated Overlay on the skeleton main body 6.

[0013] The frame body 6 and the bosses 8 on both sides can be made of cast steel or ductile iron. Since the former can be economical while ensuring performance, and it is difficult to cast integrally with ductile cast iron, it is preferred The former, that is, the skeleton main body 6 and the bosses 8 on both sides are made of cast steel.

[0014] The material of the cladding layer 7 is wear-resistant rubber.

[0015] During manufacture, the skeleton main body 6 and the bosses 8 on both sides are poured into a mold to form an integral body, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com