Refrigerator and freezer

A refrigerator and condenser technology, which is applied in the field of refrigerating and refrigerating refrigerators, can solve the problems of difficulty in increasing the condensation capacity, reducing air circulation, and difficulty in ensuring the condensation capacity of the main body of the refrigerating and refrigerating refrigerator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

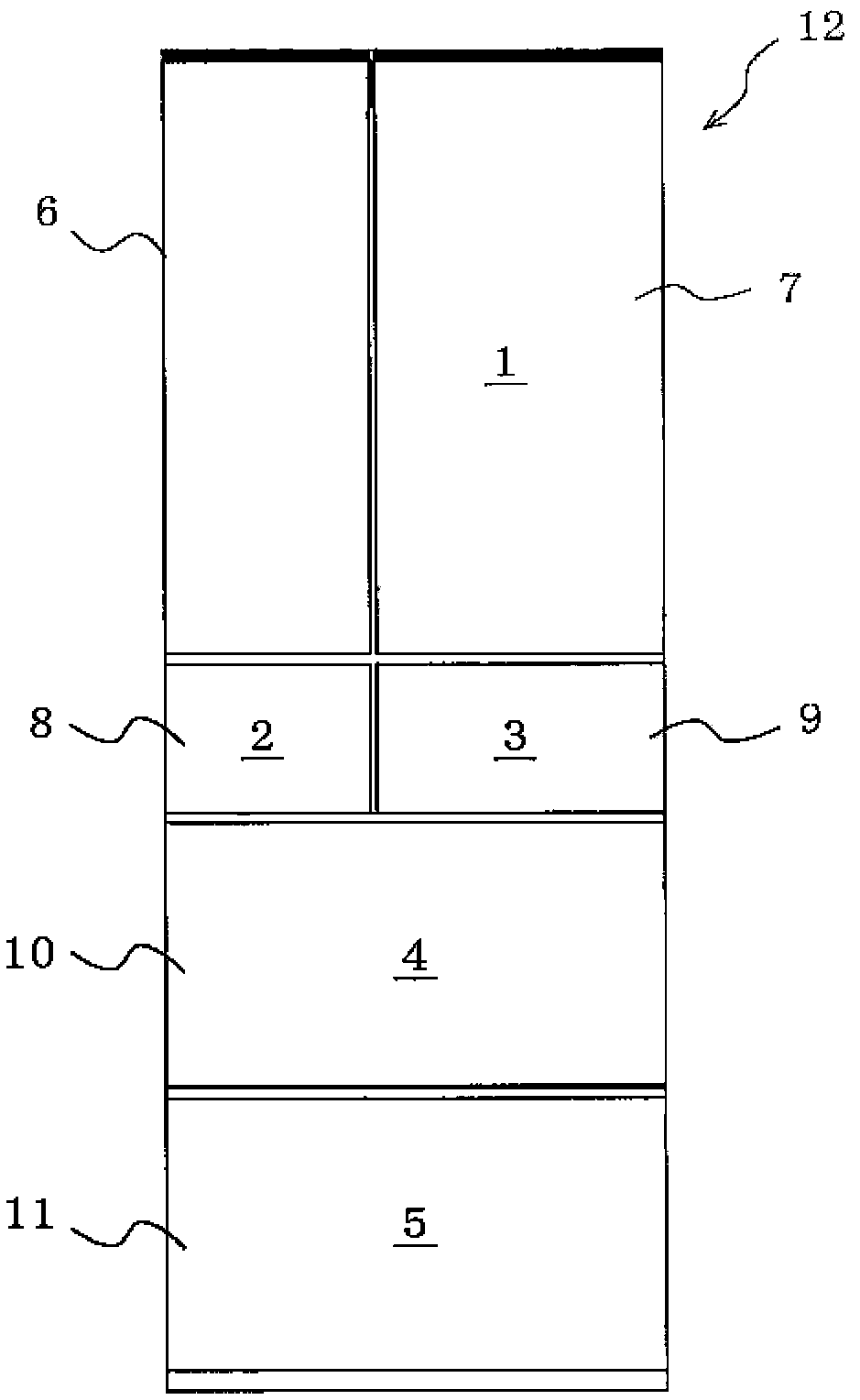

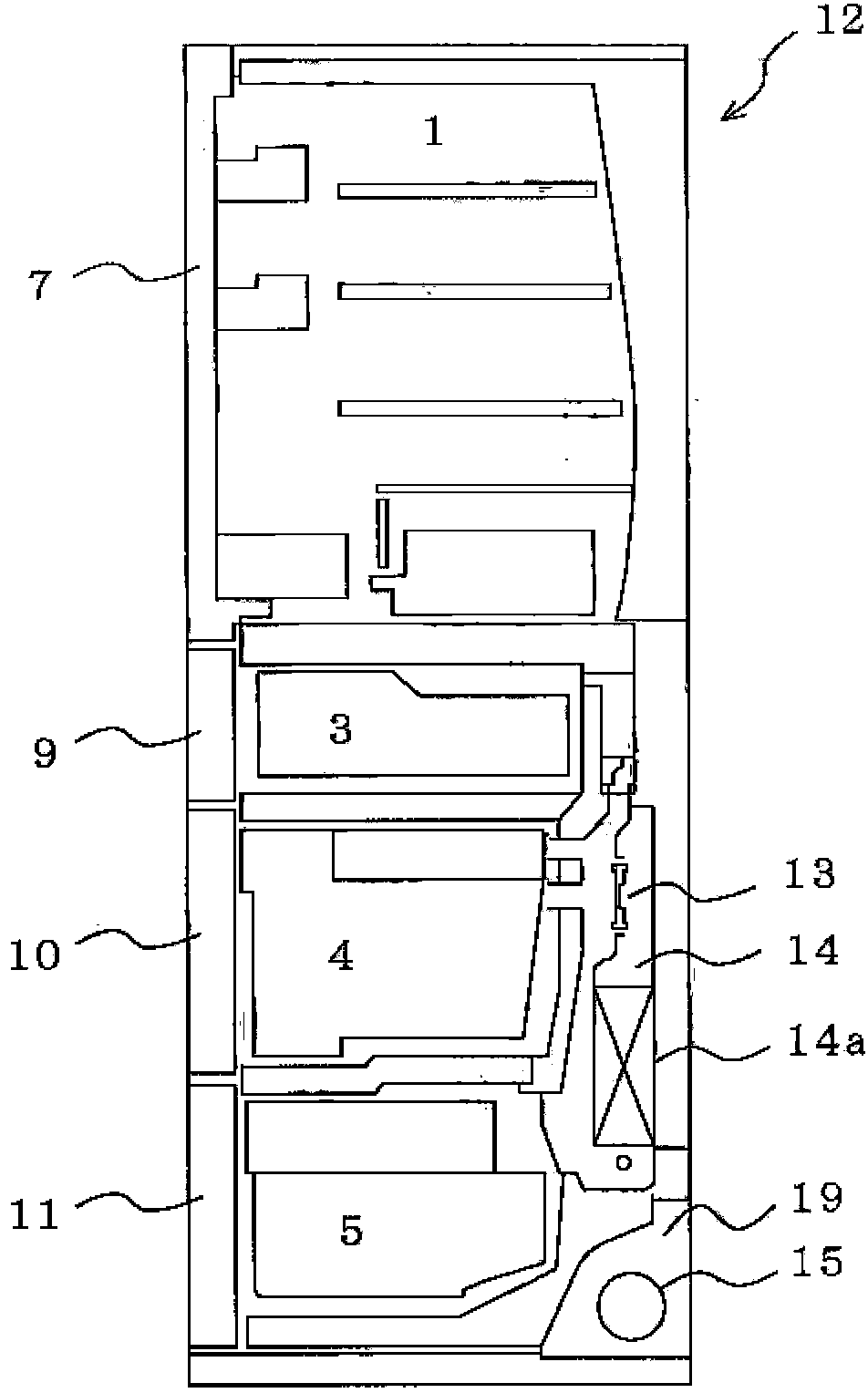

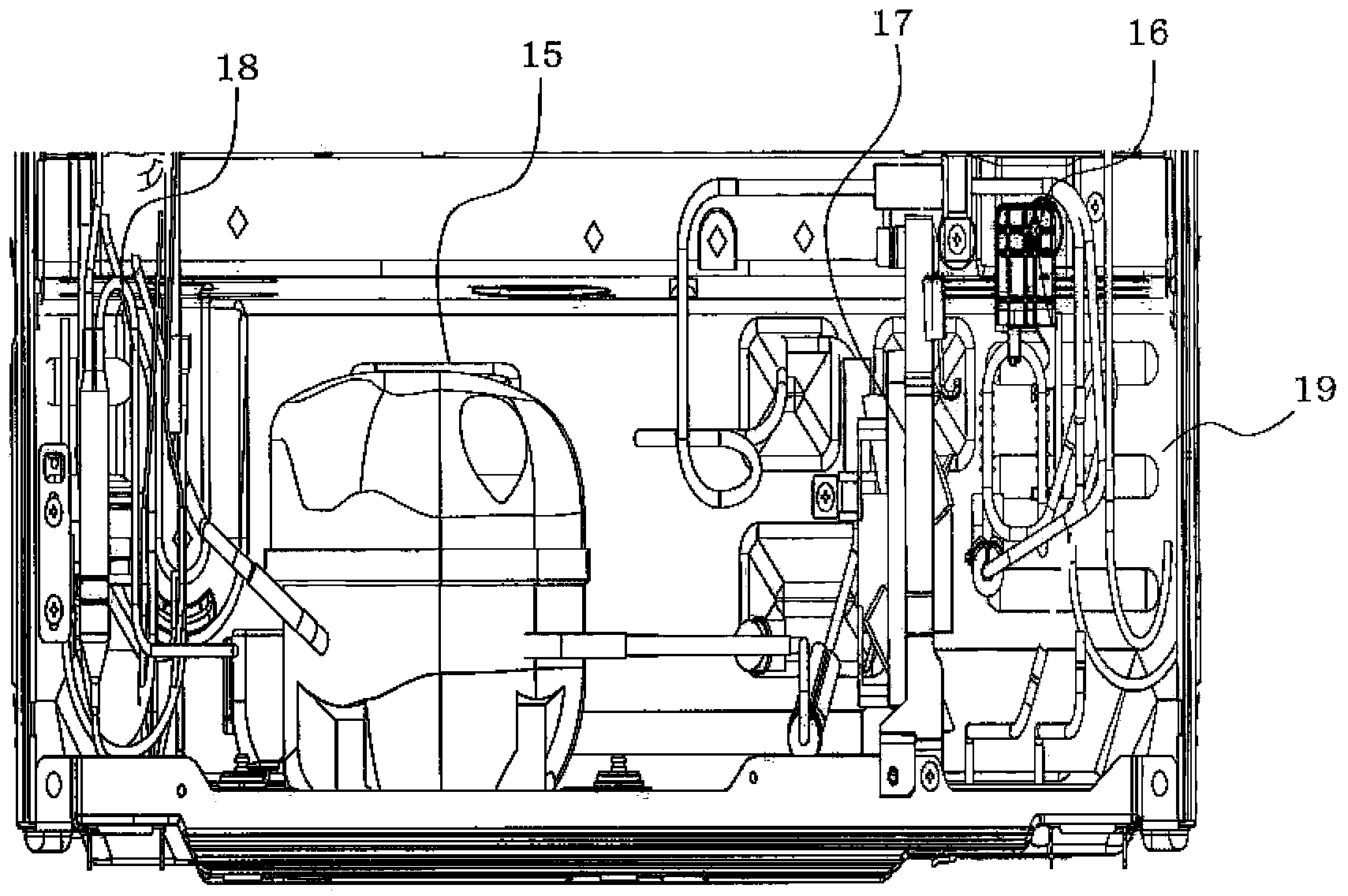

[0031] figure 1 It is a front view of the freezer-refrigerator according to Embodiment 1 of the present invention, figure 2 It is a side sectional view of the freezer-refrigerator according to Embodiment 1 of the present invention, image 3 It is a front view which shows the inside of the machine room provided in the back lower part of the freezer-refrigerator concerning Embodiment 1 of this invention.

[0032] exist Figure 1 to Figure 3 Among them, the main body 12 of the freezer-refrigerator is formed by filling the space between the outer box and the inner box with heat insulating members such as foamed polyurethane. In the main body 12 of the freezer-refrigerator, a plurality of storage chambers with front openings are provided by partition walls integrally formed with the main body 12 of the freezer-refrigerator. For example, a refrigerating chamber 1 is provided on the uppermost layer of the main body 1 of the freezer-refrigerating refrigerator, and an ice-making ch...

Embodiment approach 2

[0049] In Embodiment 2, in addition to the air intake port 21 of the duct 25 , a lower air intake port is provided in the lower cover portion 27 of the duct 25 .

[0050] Figure 7 It is a perspective view which shows the lower cover part of the duct of the freezer-refrigerator which concerns on Embodiment 2 of this invention, Figure 8 It is a side sectional view showing the duct arranged in the lower part of the freezer-refrigerator according to Embodiment 2 of the present invention and the machine room in the lower part of the back, Figure 9 It is a temperature contour diagram in the duct of the freezer-refrigerator in Embodiment 2 of this invention. In addition, the same code|symbol is attached|subjected to the same part as Embodiment 1. As shown in FIG.

[0051] The aforementioned lower suction port 28 is as Figure 7 As shown, it is provided at the bottom of the lower cover portion 27 on the side of the air inflow path 23 . The lower air inlet 28 is formed in a long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com