Flexible torque transmitting device

A torque transmission device and flexible technology, applied in the field of transmission, to achieve the effect of reducing the interference of dynamic loads and stabilizing the adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

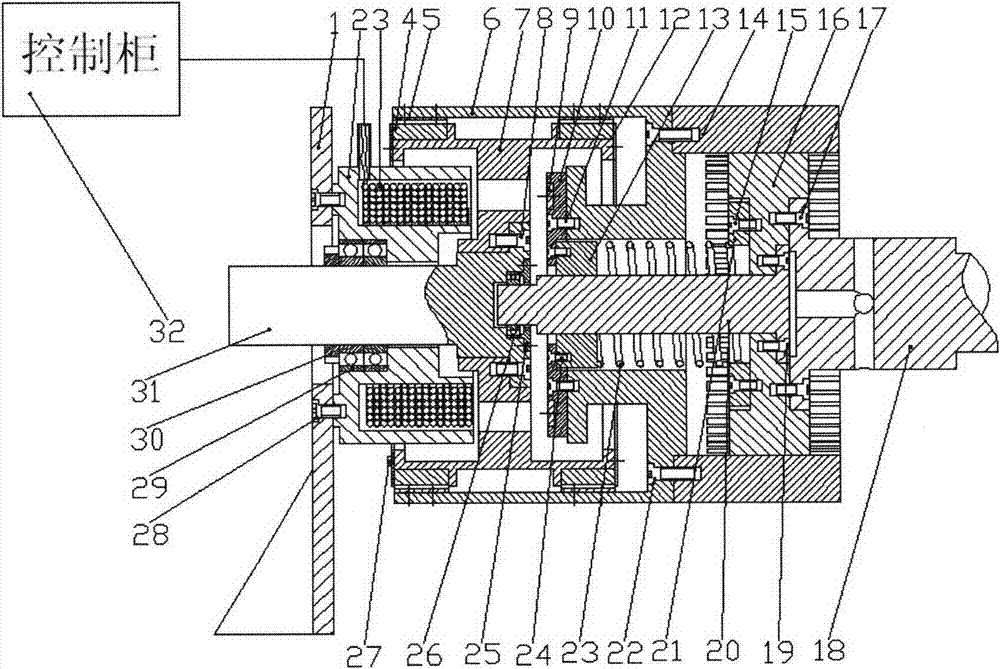

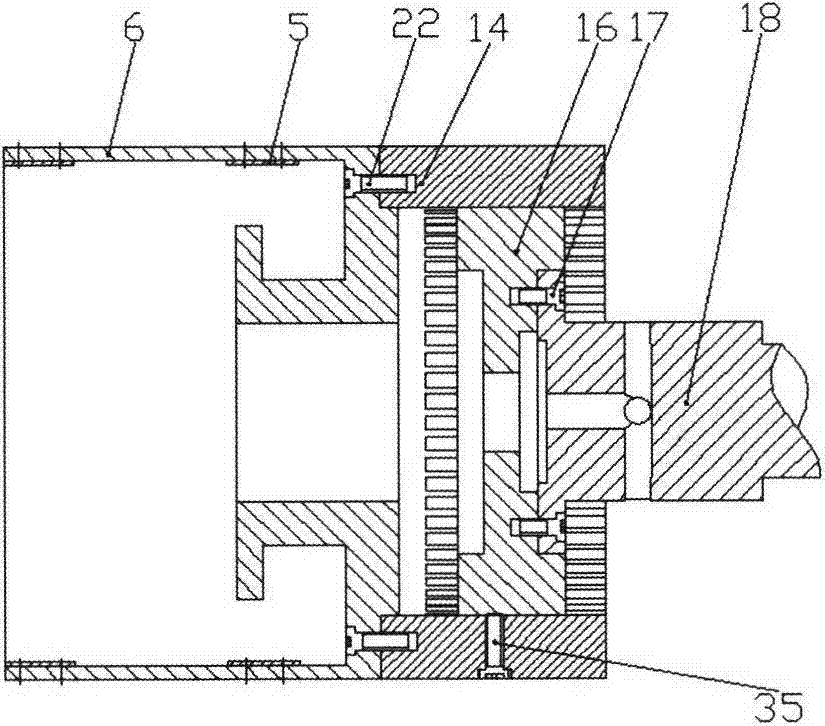

[0030] A flexible torque transmission device includes an input device, an output device and an adjustment device. The input device includes an input shaft 18, a conductor barrel 6, and a conductor ring 5; the output device includes a permanent magnet 4, a permanent magnet barrel 7, and an output shaft 31; the adjustment device includes a spline 16, a spline sleeve 14, a guide post 20, and an elastic body 23 , coil group 3 , coil fixed body 2 , transition flange 10 . Output shaft 31 is connected with permanent magnet cylinder 7 by screw 8, and the outer cylinder of permanent magnet cylinder 7 is made of magnetically conductive material, as long as there is a certain strength and rigidity, permanent magnet 4 is installed on the outer surface of permanent magnet cylinder 7 , The permanent magnet 4 is made of a strong permanent magnet material; the conductor ring 5 is installed on the inner surface of the conductor cylinder 6, the conductor ring 5 is an electrical conductor and ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com