Self-protection H bridge driving circuit

A bridge drive circuit and self-protection technology, which is applied in the field of H bridge drive circuit, can solve the problems of high cost, poor flexibility, and occupying a large PCB area, and achieve the effect of small quantity, simple construction, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

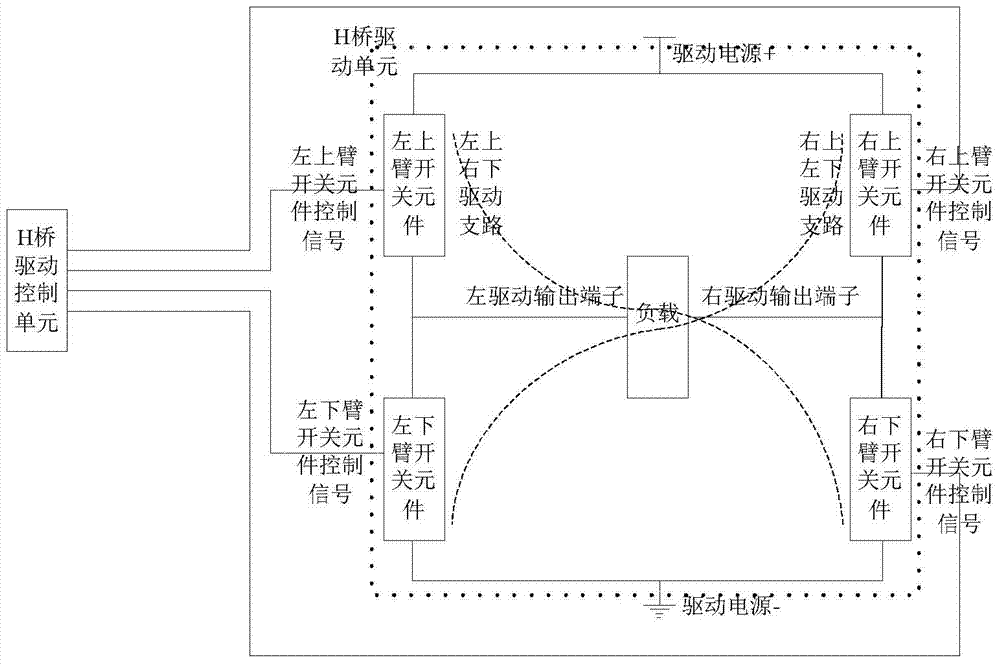

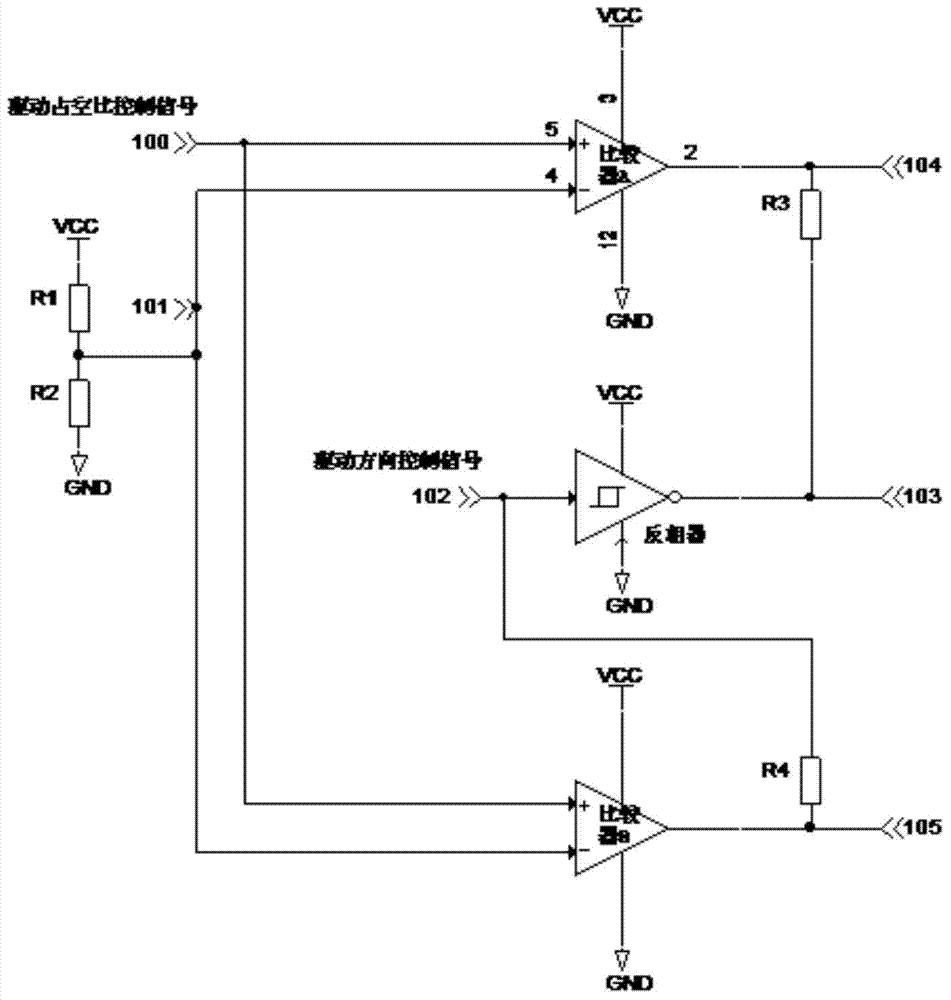

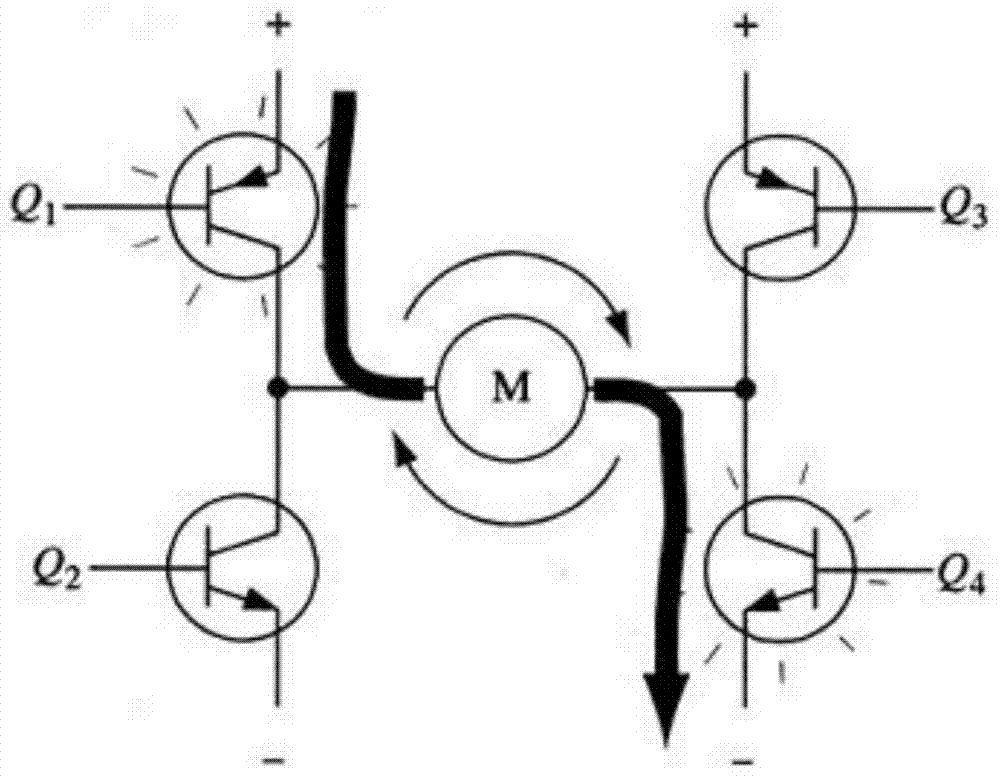

[0013] refer to figure 1 . In the embodiment described below, the self-protection H-bridge drive circuit includes an H-bridge drive control unit and an H-bridge drive unit, wherein the H-bridge drive unit is composed of two drive output terminals, four switch elements, and four switches The components are on the diagonal. The switching elements of the left upper arm and the right lower arm form a left upper right lower driving branch, and the right upper arm and left lower arm switching elements form a right upper left lower driving branch. The above two driving branches are controlled by the H bridge. The drive control unit controls the alternate conduction and controls the direction of the load drive current. In the same drive branch, one switch element controls the output of the load drive current, and the other switch element controls the duty ratio of the load drive current; the H bridge drive unit uses an inverter A phaser channel, two comparator channels and four resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com