Device for damping vibration and limiting torque

A torque and damping technology used in mechanical equipment, clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

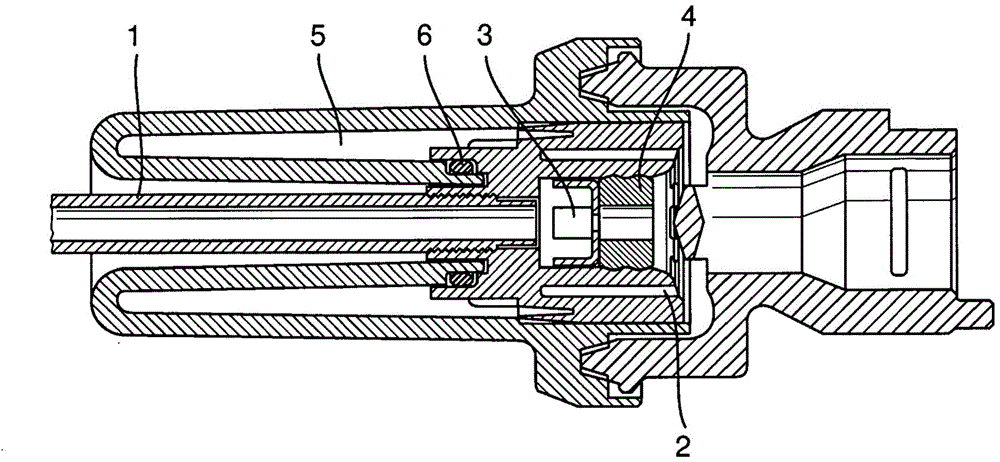

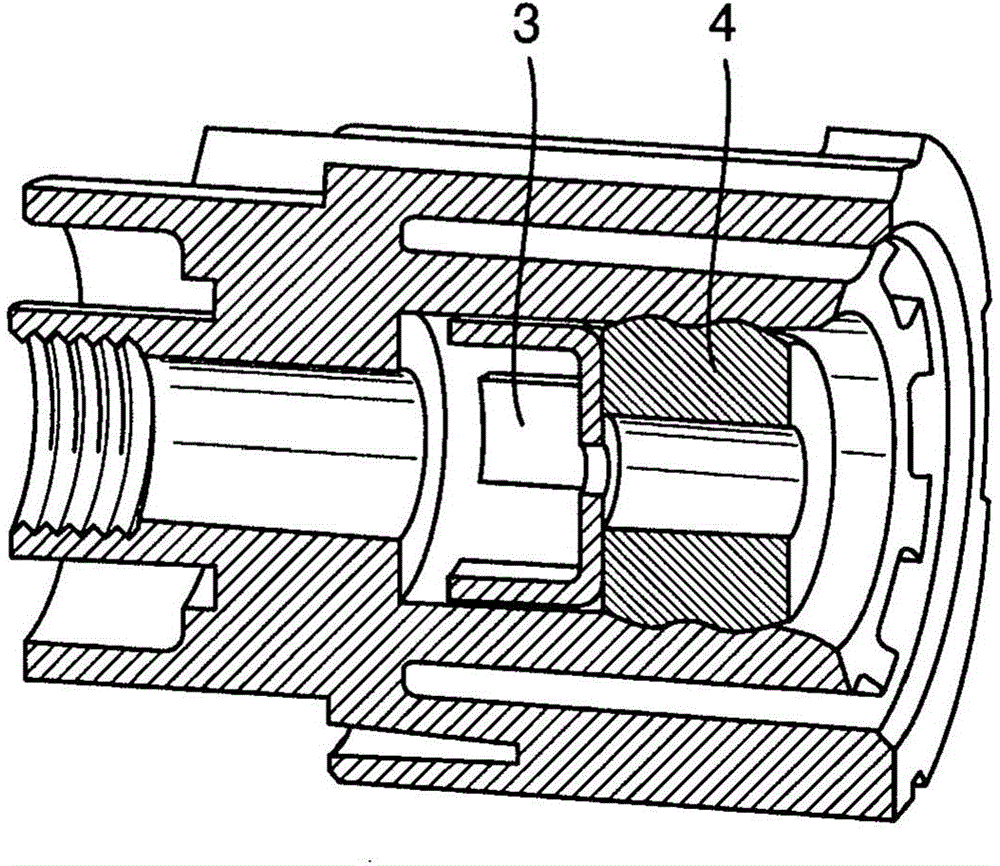

[0012] figure 1 A cross-sectional view of a device for damping vibrations and limiting torque according to the present invention is shown. The device for damping vibrations and limiting torque is connected to a hydraulic line 1 and on the right side of the device has a receptacle for a connector by means of which the device can be connected to another pressure line. Inside the device for damping vibrations and limiting torque there is an insertion device 2 which is connected to the fluid line 1 . In this case, the connection can be made materially, positively or non-positively, for example by welding, wedging, clamping or the like. Connected to the insertion device 2 is a housing 5 in which a channel is formed for forming a Helmhertz resonator. The sealing between the housing 5 and the insertion device 2 is achieved by a sealing ring 6 , which is arranged between the housing 5 and the insertion device 2 . The channel in the housing 5 is connected to the inner chamber of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com