Shear of backpack-type mulberry branch cutting machine

A knapsack, mulberry technology, applied in the field of scissors and knapsack mulberry tree cutting machines, can solve the problems of high battery cost, complex structure, low fuel utilization rate, etc., to improve power utilization rate, good stress stability, The effect of increasing the cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

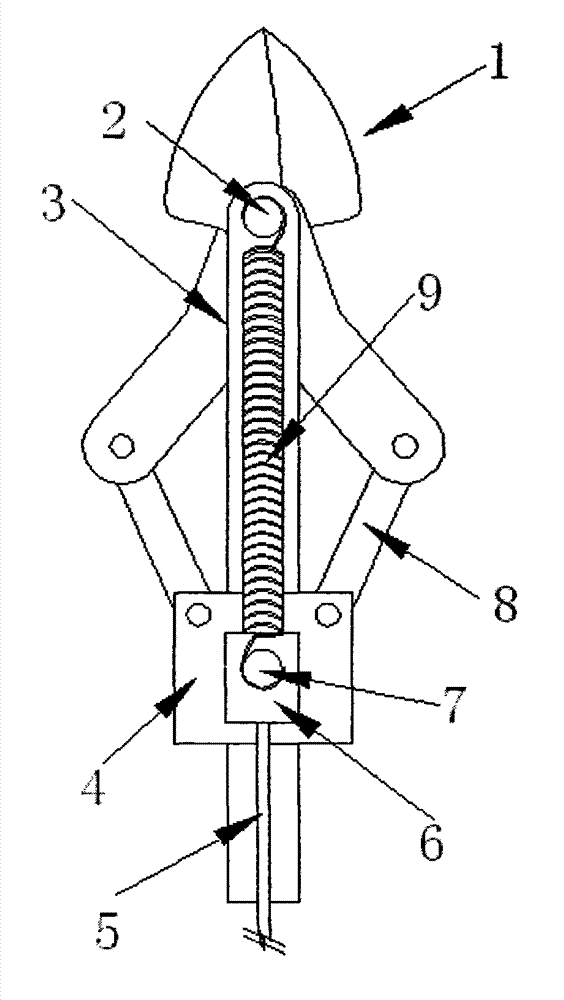

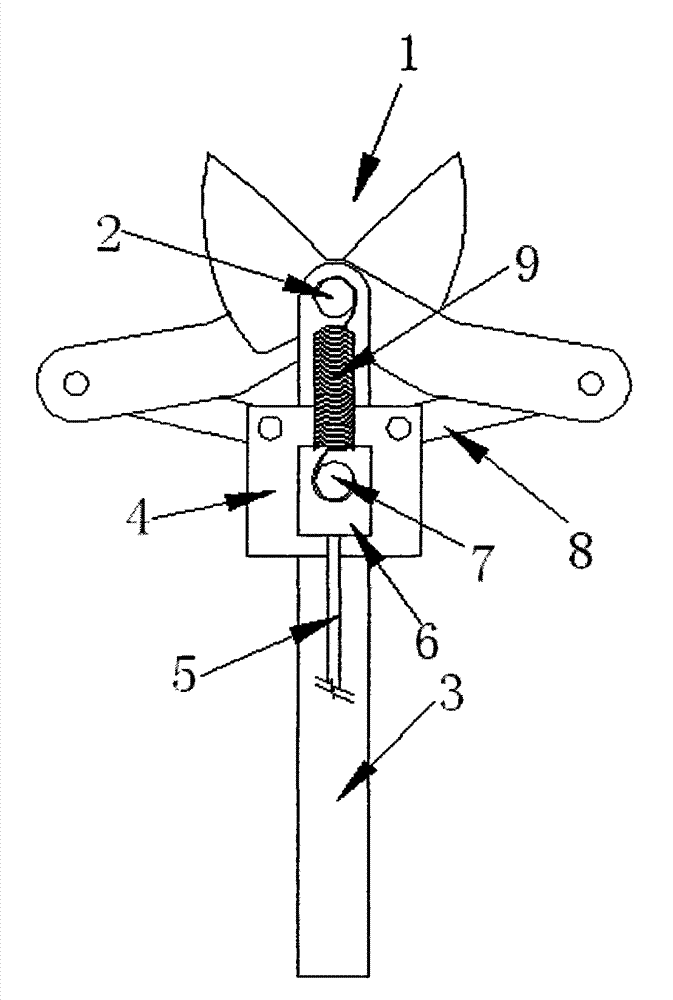

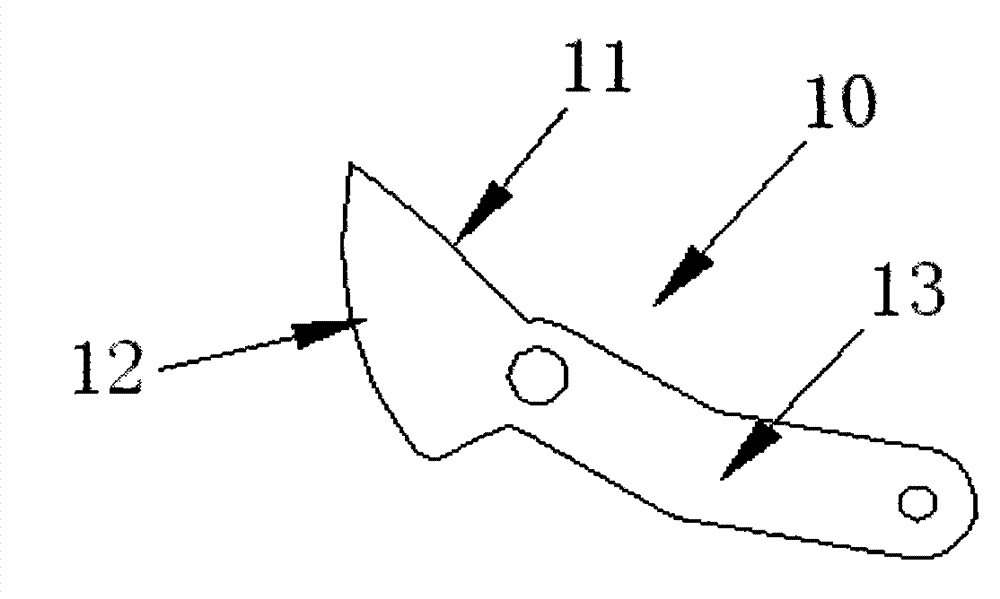

[0017] See the figure, the structure of the backpack type mulberry tree cutting machine shears of the present invention comprises scissors 1, and the structure of scissors 1 comprises two blades 10 crossed and hinged together, and blade 10 has a knife-edge part 12 and a handle 13 connected as one. Two blades 10 are hinged on the front end of coupling rod 3 by pivot 2, wherein, knife-edge part 12 stretches to the front end outside of coupling rod 3 on the blade 10, handle 13 part stretches to the rear end of coupling rod 3 on the blade 10, two The cutting edges 11 on the cutting edge portion 12 of the blade 10 face each other.

[0018] The coupling rod 3 is in the shape of a flat strip, on which a slider 4 is slidably arranged, and the slider 4 is movably connected to the handle 13 of the blade 10 through the coupling piece 8 . Specifically, the connecting piece 8 is two pieces, one end of a connecting piece 8 is hinged with the handle 13 outer end of a blade 10 , and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com