Inward-pushing-type clamping device of three-dimensional corner clamping tube in numerically-controlled tube bending machine

A three-dimensional, clamping device technology, applied in the field of push-in clamping devices, can solve the problems of performance degradation at damaged parts, easy loosening of bent pipes, abnormal deformation, etc., achieve high processing accuracy and avoid uneven movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

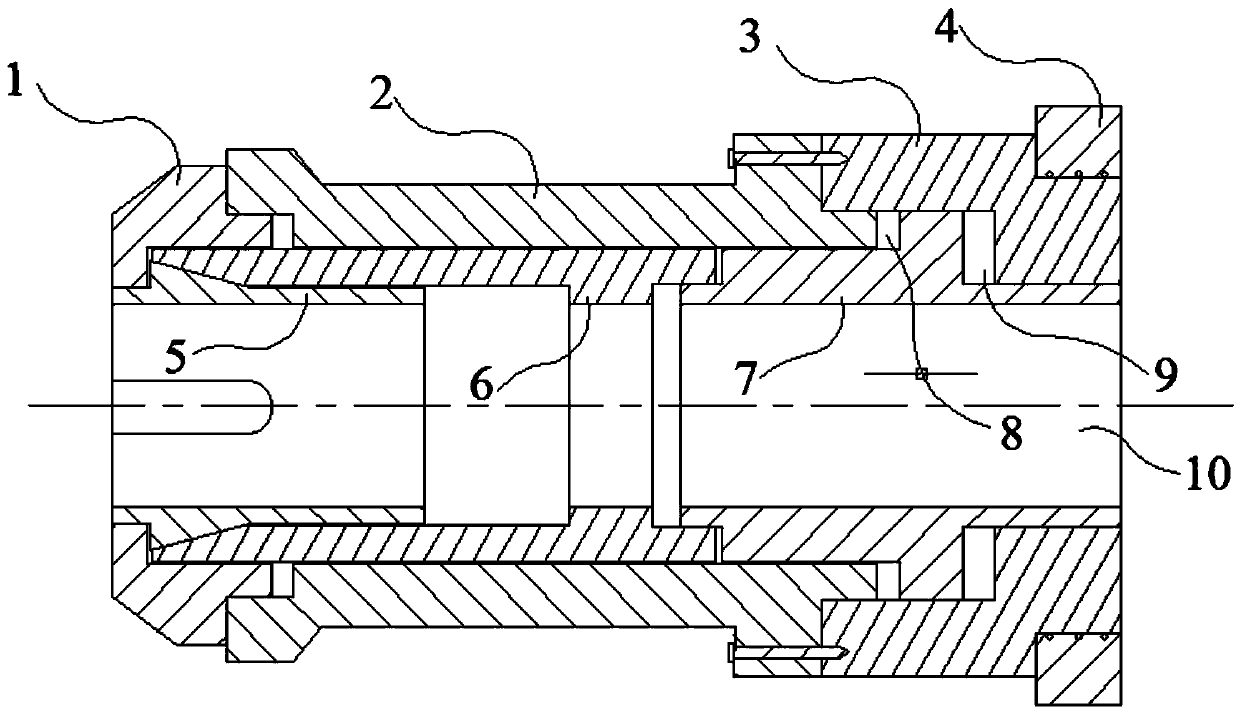

[0034] Such as figure 1 As shown, an internal push clamping device for a three-dimensional three-dimensional corner clamping pipe in a CNC pipe bender includes an elastic chuck 5, and also includes a top fixing sleeve 1, an outer fixing sleeve 2, a hydraulic outer cylinder 3, a bearing 4, The inner pushing sleeve 6, the hydraulic inner cylinder 7, the first hydraulic chamber 8 and the second hydraulic chamber 9, the top fixing sleeve 1, the outer fixing sleeve 2, the hydraulic outer cylinder 3, the bearing 4, the elastic chuck 5, the inner pushing The sleeve 6, the hydraulic inner cylinder 7, the first hydraulic chamber 8 and the second hydraulic chamber 9 are all rotationally symmetrical structures, have a common central axis, and jointly form a clamping cavity 10 inside;

[0035] The shape of the elastic chuck 5 is a circular tube with a ring of protrusions on the outside. The protrusions are composed of two sides, the left side and the right side. The left side is perpendicula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com