Water-saving type strip steel pickling line and method capable of recycling hydrogen and without pumping and discharging acid mist

A water-saving and acid mist technology, which is applied in the field of strip steel pickling equipment manufacturing, can solve the problems of wasting acid liquid, high production cost, unfavorable acid mist condensation, etc., and achieve the effect of reducing water consumption and expanding the concentration difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

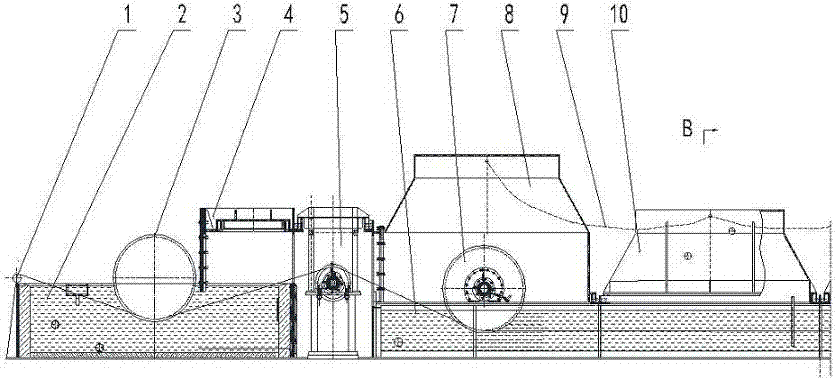

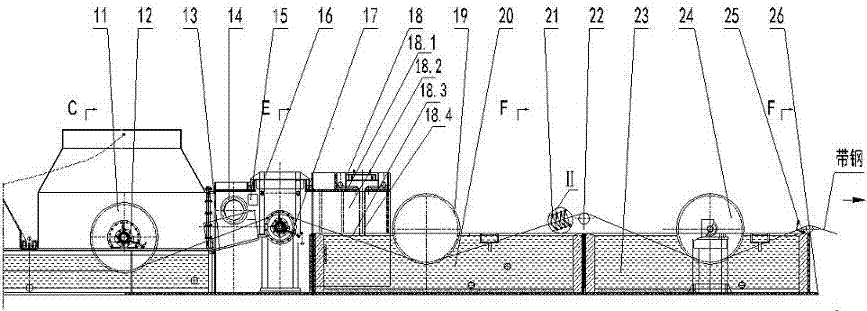

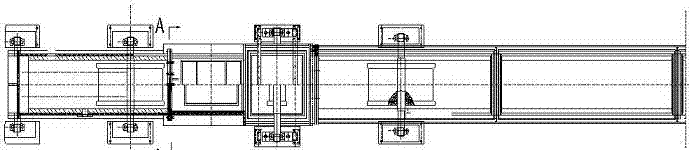

[0051]Embodiment 1: with reference to accompanying drawing 1-13. Hydrogen can be recovered without acid mist and water-saving strip steel pickling line. The feeding roller 1 is located at the front end of the water tank 2; the water tank pressure roller 3 is located in the water tank 2; Insert the lower end of the lower end into the water in the water tank 2; the belt inlet limit and redirection assembly 5 is located between the water tank 2 and the acid tank 6; the acid tank inlet belt pressure roller 7 and the acid tank outlet belt pressure roller 11 are respectively located part and rear; acid tank inlet belt pressure roller top cap 8, acid tank top hat 10 (multiple pieces) and acid tank outlet belt pressure roller top hat 12 water seal cover on acid tank 6, and acid tank inlet belt pressure The roll 7 and the acid tank outlet pressure roller 11 are covered in it; the hydrogen gas series pipe 9 feeds the acid tank into the belt pressure roller top cap 8, the acid tank top c...

Embodiment 2

[0052] Example 2: On the basis of Example 1, hydrogen can be recovered without pumping out acid mist and a water-saving strip steel pickling line. The strip steel first passes through the belt feed roller 1 and enters the water tank 2, and presses the roll in the water tank 3 The lower roller surface passes through and enters the plug-in water seal assembly 4 area at the lower end of the sealing plate. When the strip steel is submerged in the water, the sealing plate 4.6 completely seals off the space on the water surface at its entrance, and then the strip steel passes through the inlet limit. Position and reversing assembly 5, redirected by the reversing roller, enters the acid tank 6 downwards, passes through the acid tank into the belt pressure roller 7 and the acid tank exits the lower roll surface of the belt pressure roller 11, and there is an acid tank in the air above the passing area Into the belt pressure roller top cap 8, hydrogen series pipe 9, acid tank top cap 10...

Embodiment 3

[0053] Embodiment 3: On the basis of Embodiment 2, the steel strip is immersed in the cleaning tank 20, and the liquid surface 18.3 of the submerged section forms with the overflow water seal upper plate 18.1 and the overflow water seal side plate 18.2 of the overflow water seal assembly 18 In a simple space, the water curtain 18.4 from top to bottom in the space pumped by the water pump 18.5 melts the acid mist that touches, so that no acid mist escapes from this port.

[0054] Preparations before production:

[0055] Disassemble the upper limit shaft frame cover and the upper limit shaft frame cover 16.1 of the belt inlet limit and redirection assembly 5 from their respective installation brackets, and remove the acid tank inlet belt pressure roller top cap 8 and the acid tank outlet belt. Disassemble and remove the connecting parts of the pressure roller top cap 12, remove the condensate downflow cover 4.1, remove the acid tank top cap 10, and then sequentially thread the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com