Metal nano-powder slurry scraping tool

A metal nano and powder technology, applied in the field of chemical manufacturing, can solve the problem of lack of metal nano powder slurry processing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

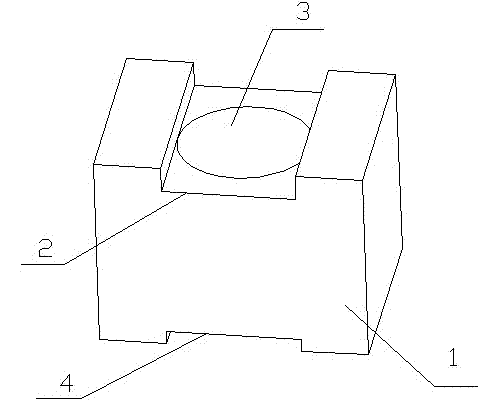

[0014] The main purpose of squeegeeing is: after the metal nano powder forms a slurry, make the slurry into a slurry plane, and observe the flatness of the plane through an electron scanning microscope, so as to intuitively judge the dispersion effect of the metal nano powder. The squeegee tool is a tool for making nano powder into slurry under the conditions of simulating the customer's practical product, so as to test the dispersion effect of the slurry. Such as figure 1 As shown, the present invention provides a metal nano powder squeegee tool, including a squeegee metal column 1, the squeegee metal column 1 is a cuboid or a cube, and a first squeegee is provided on the upper surface of the squeegee metal column 1 The port 2 is provided with a through hole 3 in the scraping port, and the through hole 3 leads to the lower surface of the cylinder. Scraping metal column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com