Adjusting device of machine vision inspection system

A technology for machine vision detection and adjustment devices, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of few adjustment methods and single detection functions, and achieve the effect of wide application and multiple adjustment functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

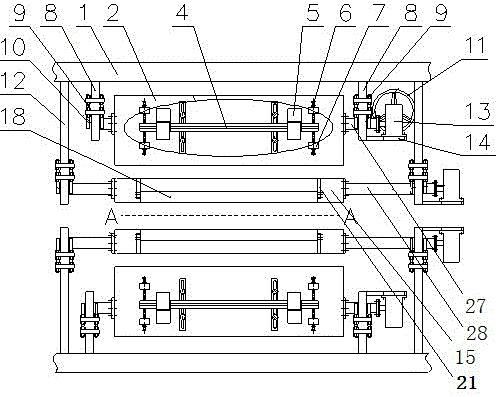

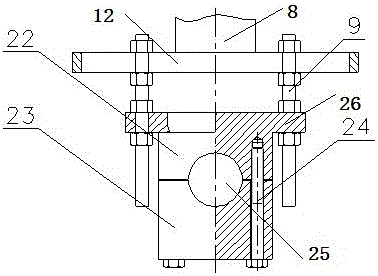

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is further described, as figure 1 and Figure 5 As shown, the adjustment device of the machine vision inspection system includes a pair of symmetrical sub-adjustment devices distributed up and down; the sub-adjustment device includes a frame 1, a camera assembly, and a light source assembly; the camera assembly and the light source assembly are respectively The adjustable device is installed on the frame 1, and the positions and angles of the camera assembly and the light source assembly can be adjusted through the adjustable device, so that the camera assembly of the upper side adjustment device is aligned with the light source assembly of the lower side adjustment device, and the lower side adjustment device Align the camera assembly with the light source assembly of the upper side adjustment device.

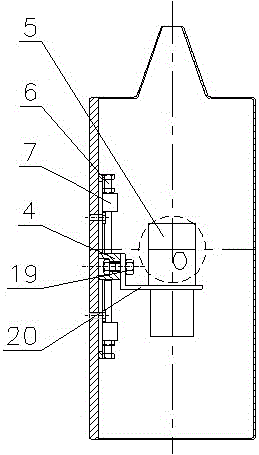

[0018] Among them, such as figure 2 As shown, the camera assembly includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com