High-speed sequence casting hot-rolling unit for large-section large-weight billet production

A large-section, full-continuous casting technology, used in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of inconvenient movement and transportation, limited adjustment functions, and small scope of application, and achieve easy movement and transportation. Adjusting the effect of various functions and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

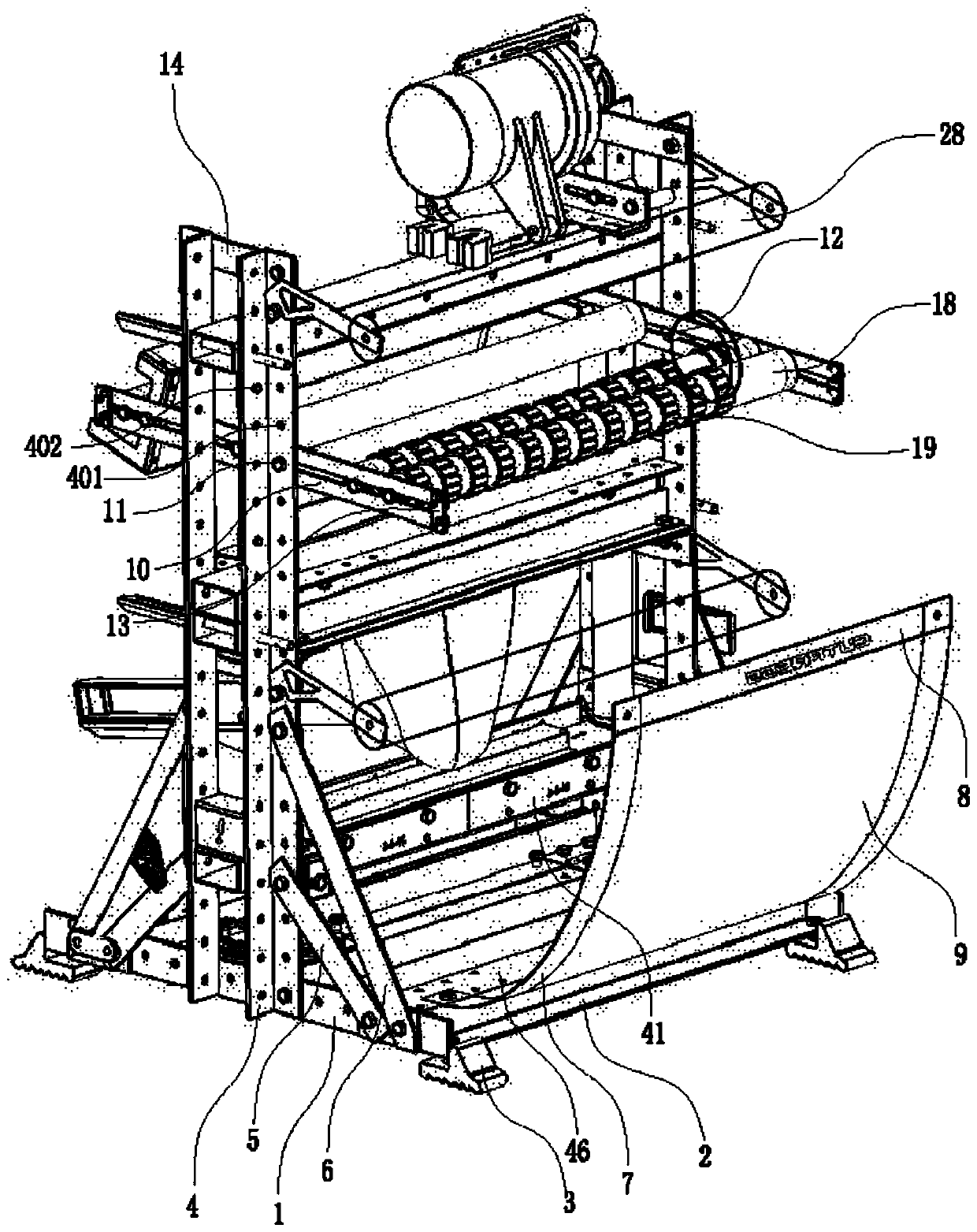

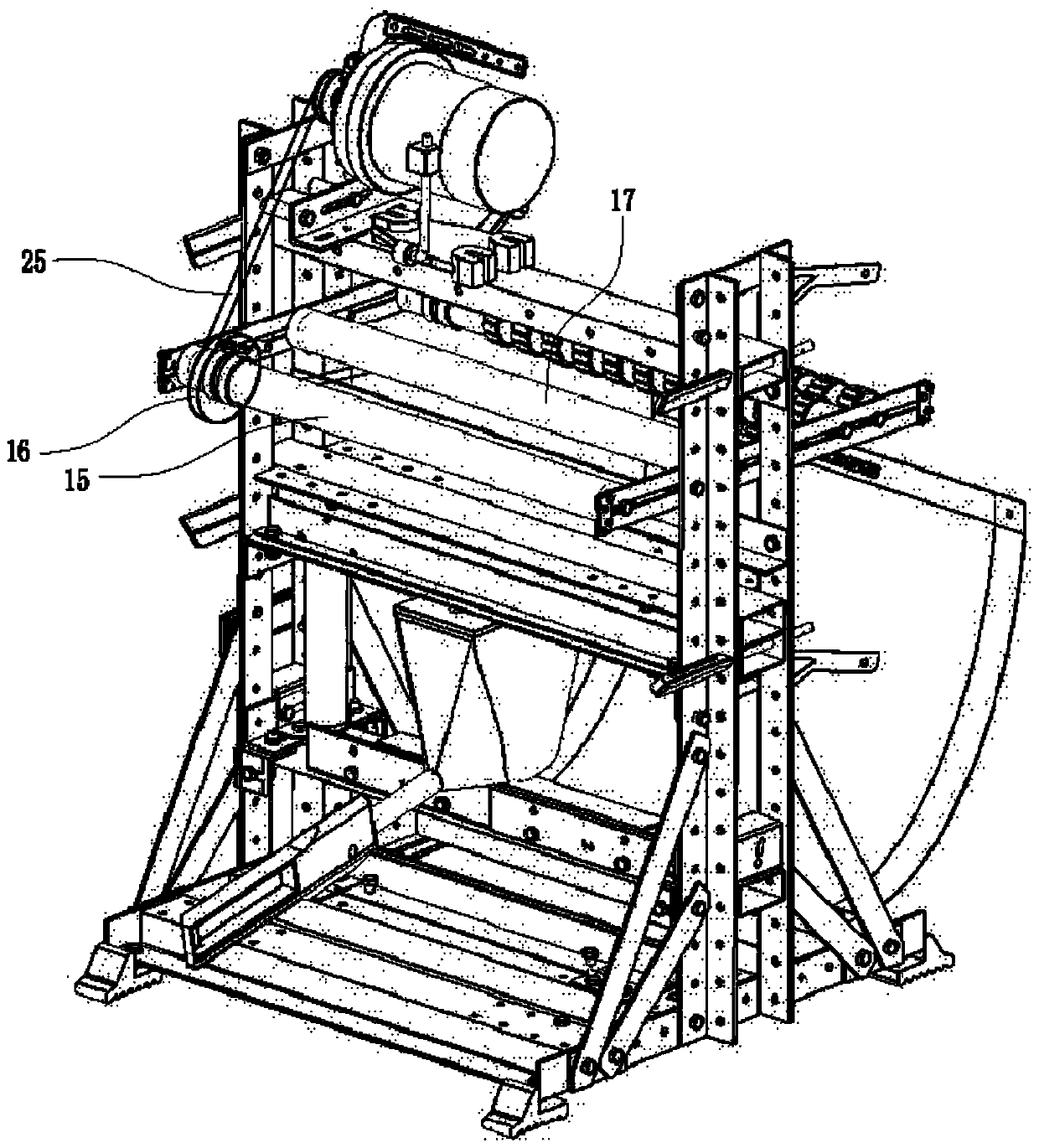

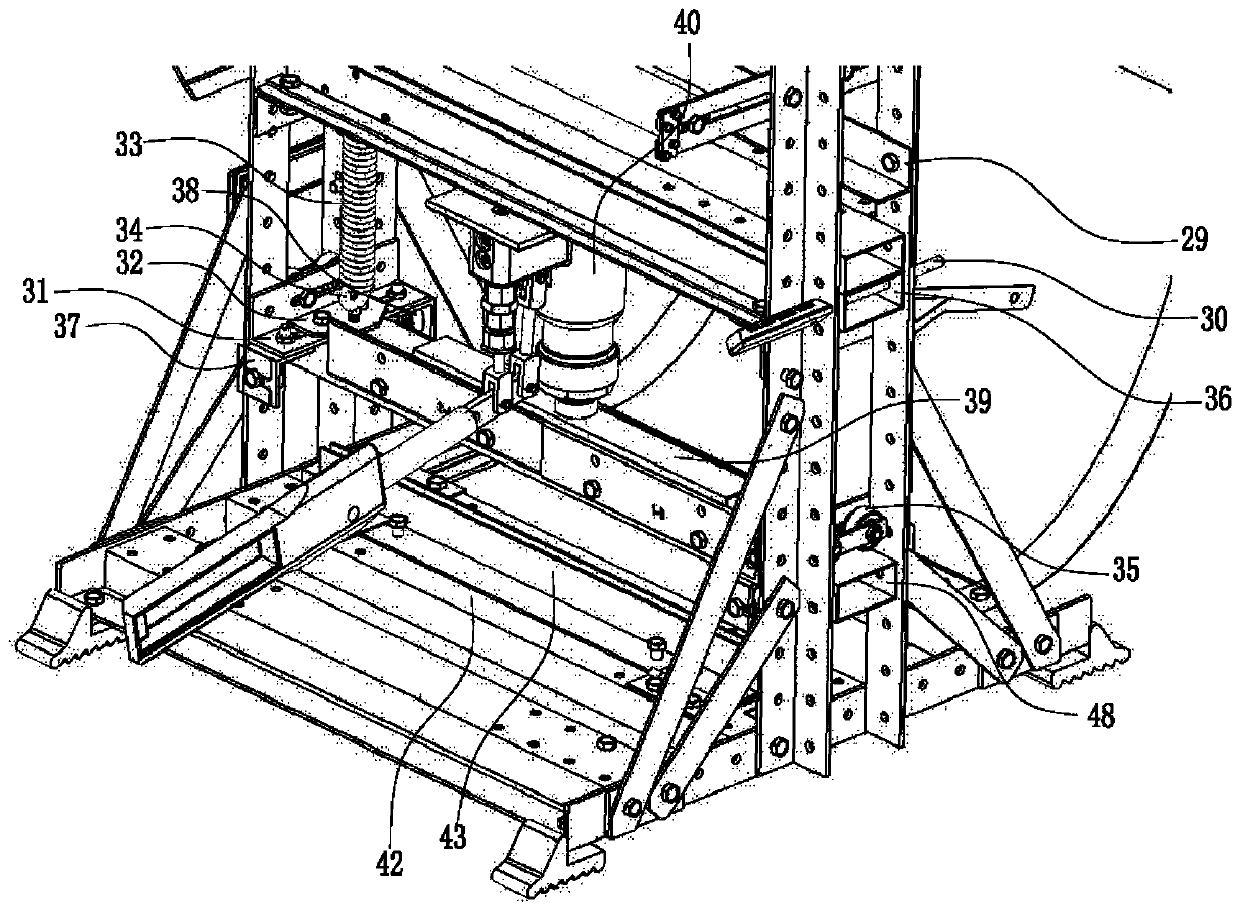

[0020] Such as Figure 1~5As shown, a high-speed full-continuous casting hot-rolling unit for the production of large-section and heavy-weight billets includes a bracket assembly, an arc-shaped side bar 7, a top bar 8, an arc-shaped supporting plate 9, a horizontal bar 10, a first Bolt 11, first nut 12, first connecting bar 13, transmission assembly, rolling assembly, driving assembly and cutting assembly; the support assembly includes two L-shaped bottom bars 1, two first square tubes 46, two brackets Bar 2, four foot pads 3, an L-shaped reinforcing bar 29, four L-shaped stays 4, four reinforcing assemblies and two second connecting bars 14, two L-shaped bottom bars 1 are horizontally and symmetrically arranged, and two A horizontally distributed and detachable first square tube 46 is arranged between the two ends of each L-shaped bottom bar 1, and a horizontally distributed support bar 2 is fixed on the outside of each first square tube 46, and each support Both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com