Automatic assembly line for automobile lamplight knob switch elastic piece contact points and work method thereof

A technology of knob switch and shrapnel contact, which is applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems that rivets of different specifications cannot be assembled, cannot achieve high efficiency, and silver points are not easy to place, etc., and achieve debugging It has the effects of convenient maintenance, saving labor costs, and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

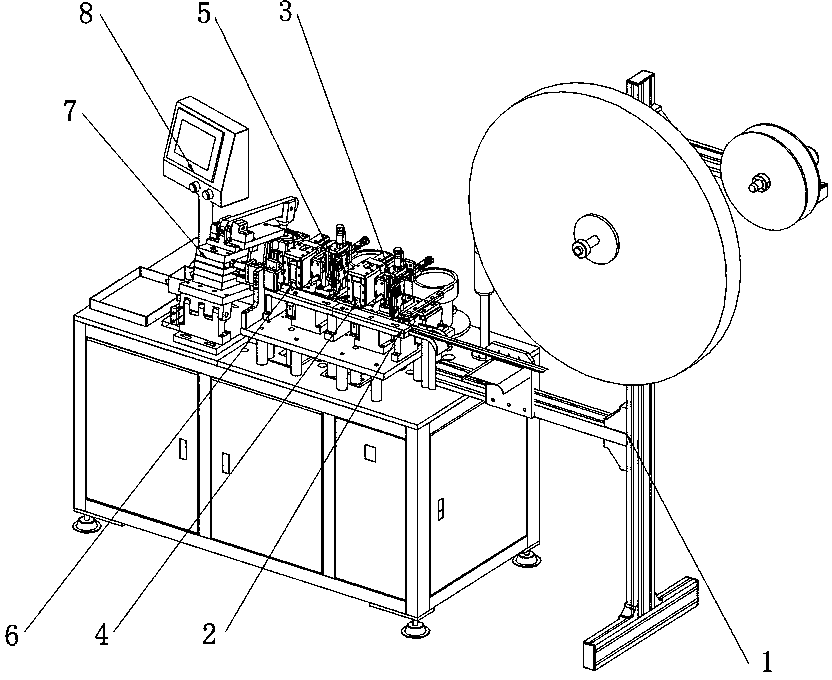

[0038] Embodiment: The overall structure diagram of the automatic assembly line of the shrapnel contact of the car light knob switch in this embodiment is as follows figure 1 shown, including sequentially mounted on the rack:

[0039] Automatic feeding station 1, used for feeding and positioning switch shrapnel strips;

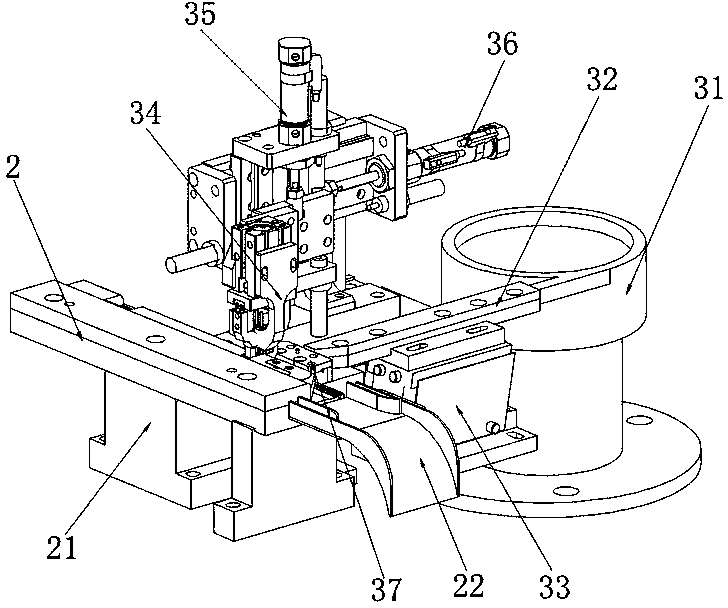

[0040] The guide runner 2, on one side of the guide runner 2, there are successively installed silver dot station 3, riveting silver dot station 4, copper dot station 5 and riveting copper dot station 6 for assembling contacts, and the guide runner 2 The end section is also equipped with a detection device and a pull belt mechanism;

[0041] Automatic discharge station 7 for separating and outputting products;

[0042] A controller 8 is also installed on the frame, and the controller 8 is connected to the detection device and the actuators of the above-mentioned stations.

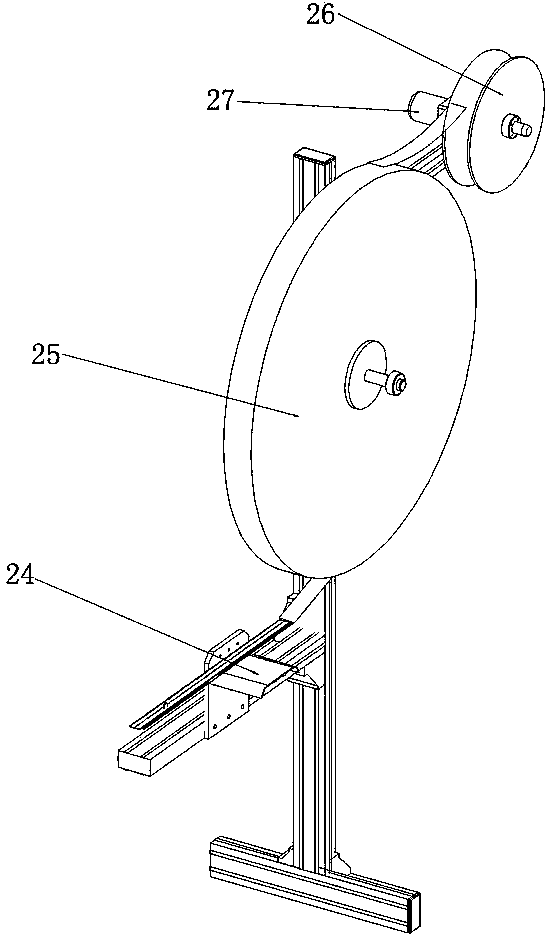

[0043] Such as figure 2 As shown, the automatic feeding station includes a transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com