PCB carrier

A technology of circuit boards and carriers, applied in the field of carriers, can solve the problems of difficult removal of circuit boards, waste of working hours and procedures, damage of circuit boards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The spirit of the present invention will be described in detail with the accompanying drawings. Anyone with ordinary knowledge in the technical field can change and modify it by the technology taught in the present invention after understanding the preferred embodiments of the present invention without departing from it. spirit and scope of the invention.

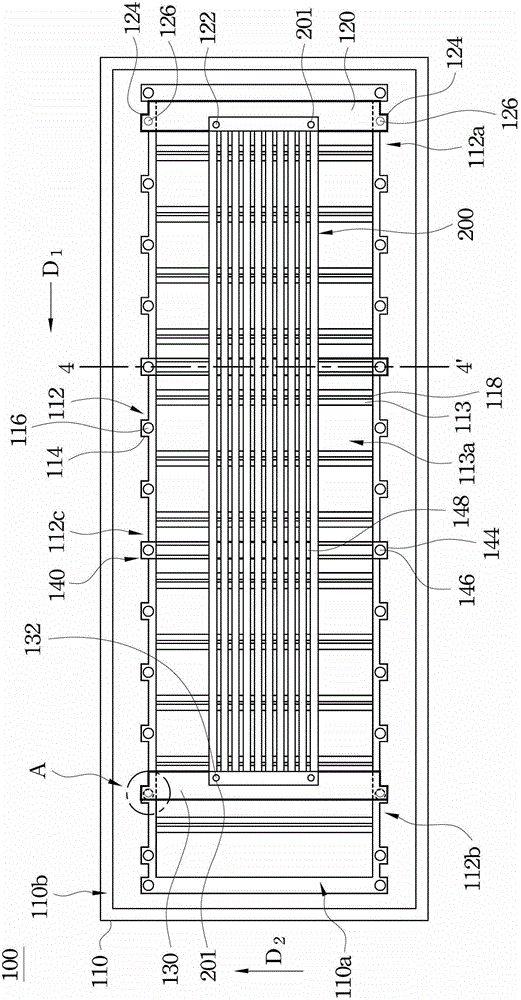

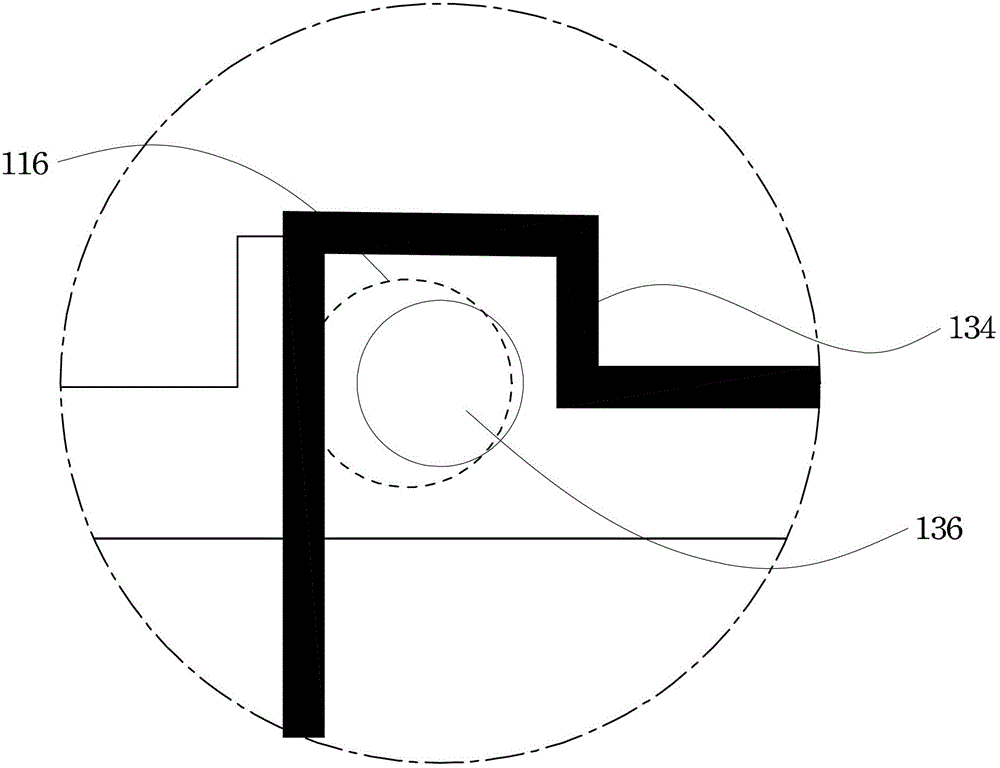

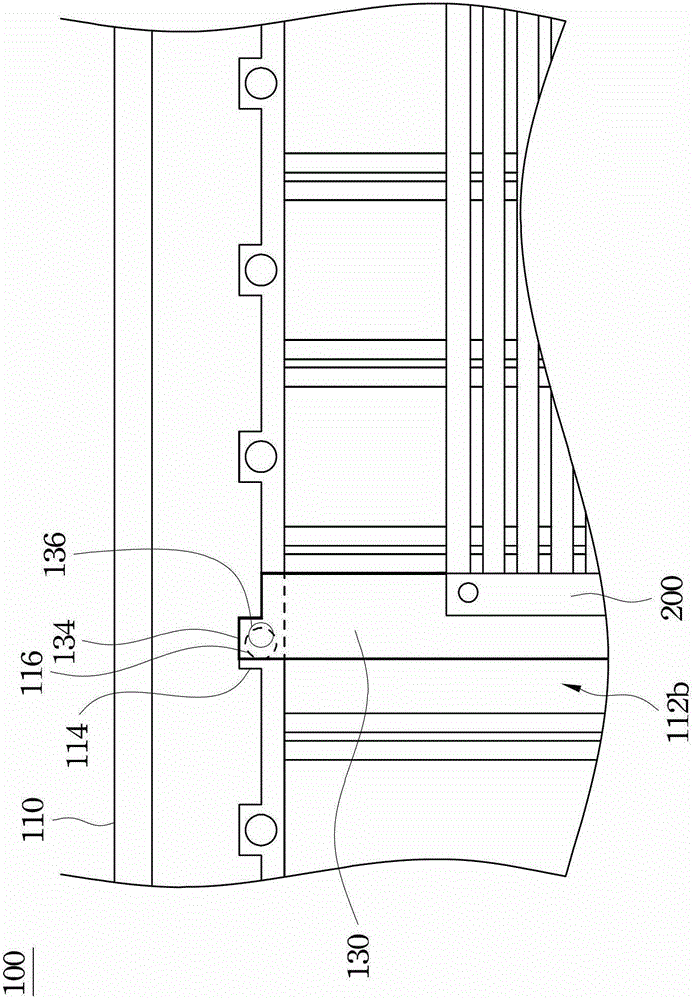

[0042] Please refer to figure 1 as well as Figure 1A , figure 1 A top view of a circuit board carrier 100 according to an embodiment of the present invention is shown. Figure 1A A partially enlarged view of part A of a circuit board carrier according to an embodiment of the present invention is shown. Such as figure 1 as well as Figure 1A As shown, the circuit board carrier 100 may include a carrier 110 , a fixing member 120 and a tension member 130 .

[0043] The carrier 110 can be divided into an accommodating groove area 110a and a non-accommodating groove area 110b, and the non-accommodating groove area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com