Semiconductor substrate for solar cell and method for manufacturing same

A solar cell, semiconductor technology, applied in the direction of semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as disadvantage, warpage of thin silicon wafers 14, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

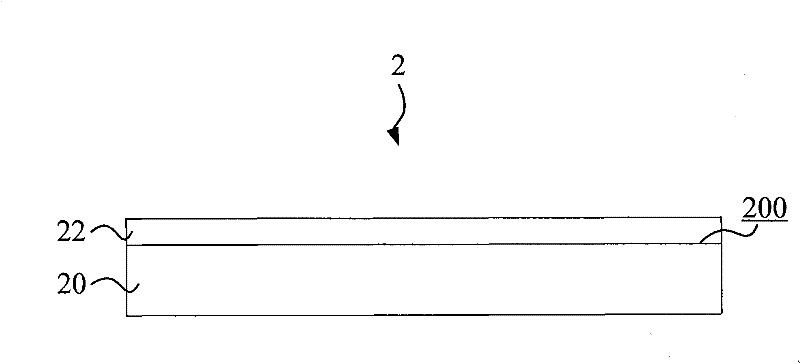

[0018] see figure 2 , figure 2 A semiconductor substrate 2 according to an embodiment of the invention is shown. The semiconductor substrate 2 can be used for solar cells.

[0019] Such as figure 2 As shown, the semiconductor substrate 2 includes a substrate 20 and a surface passivation layer 22 . The substrate 20 has an upper surface 200 .

[0020] In a specific embodiment, the substrate 20 may be made of silicon and the thickness of the substrate 20 is substantially equal to or less than 300 μm. In other words, the substrate 20 can be a thin substrate 20 .

[0021] The surface passivation layer 22 can be formed on the upper surface 200 of the substrate 20 by an atomic layer deposition process, a plasma-enhanced atomic layer deposition process or a plasma-assisted atomic layer deposition process. A layer deposition process and a plasma-enhanced atomic layer deposition process or a combined process of an atomic layer deposition process and a plasma-assisted atomic lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com