Film-shaped circuit connecting material and circuit connecting structure

A circuit connection material and electrical connection technology, applied in the direction of structural connection, conductive connection, and electrical component connection of printed circuits, can solve the problems of reduced adhesion and peeling of film-like circuit connection materials, to ensure visibility, reduce Effect of connecting resistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

[0126] (Example 1)

[0127] 400 parts by mass of polycaprolactone diol with a weight average molecular weight of 800, 131 parts by mass of 2-hydroxypropyl acrylate, 0.5 parts by mass of dibutyltin dilaurate as a catalyst, and 1.0 parts by mass of hydroquinone monomethyl ether as a polymerization inhibitor The parts are heated to 50°C and mixed while stirring. Next, 222 parts by mass of isophorone diisocyanate was dropped, and the temperature was further increased to 80° C. while stirring to perform a polyurethane reaction. After confirming that the reaction rate of the isocyanate group was 99% or more, the reaction temperature was lowered to obtain a urethane acrylate.

[0128] Using terephthalic acid as a dicarboxylic acid, propylene glycol as a diol, and 4,4'-diphenylmethane diisocyanate as an isocyanate to prepare terephthalic acid / propylene glycol / 4,4'-diphenylmethane diisocyanate A polyester polyurethane resin A having an isocyanate molar ratio of 1.0 / 1.3 / 0.25.

[0129] Next,...

Example

[0132] (Examples 2-16)

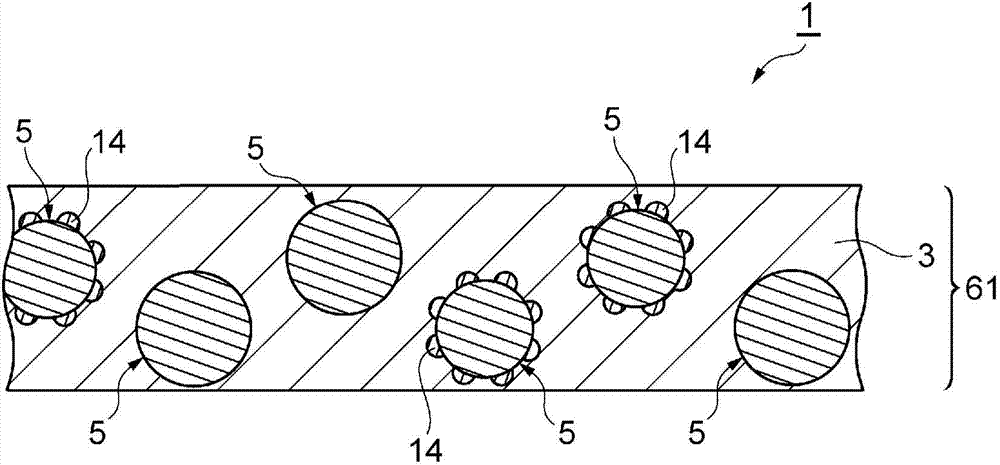

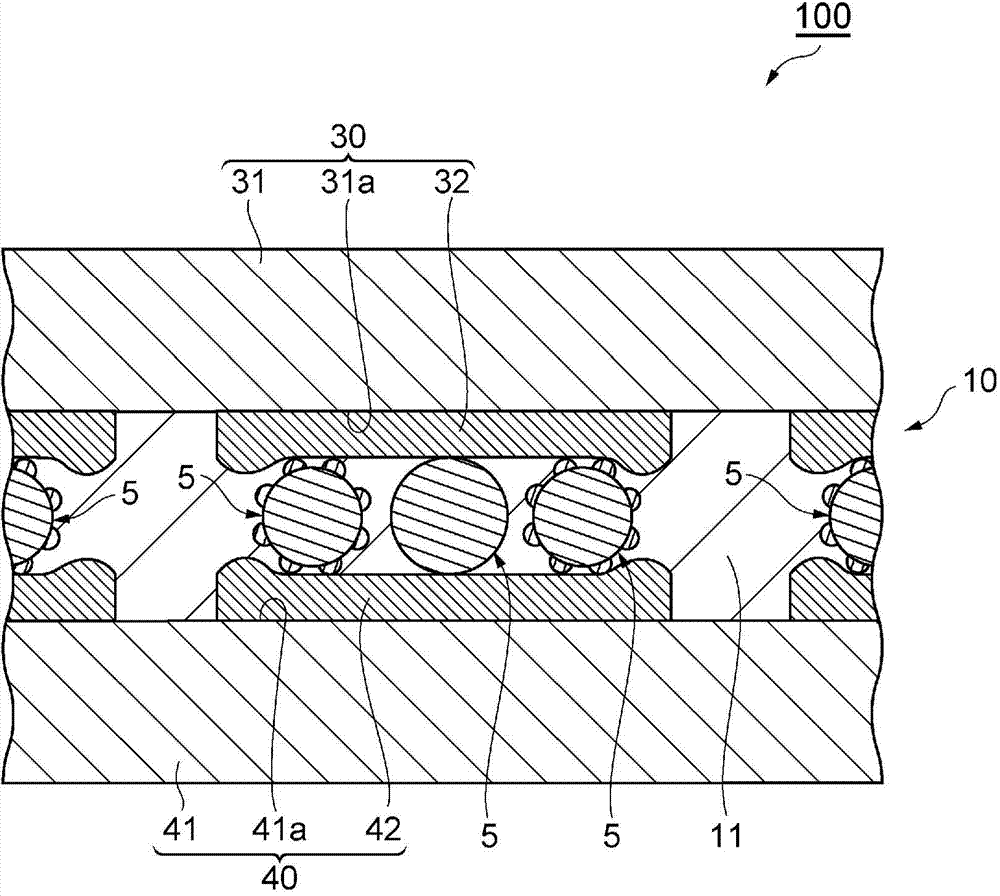

[0133] Such as Figure 5 Except that the average particle diameter of the conductive particles, the number of conductive particles, the type of dye, the amount of dye, and the thickness of the film-like circuit connection material were changed as shown, the same operation as in Example 1 was carried out to produce a film-like circuit connection material.

Example

[0134] (Examples 17, 18)

[0135] 25 parts by mass of the above-mentioned urethane acrylate as a radical polymerizable substance, 20 parts by mass of isocyanurate-type acrylate (product name: M-325, manufactured by Toagosei Co., Ltd.), and 2-methacryloyloxyethyl 1 part by mass of base acid phosphate (product name: P-2M) and 4 parts by mass of benzoyl peroxide (product name: Nyper-BMT-K40) as a free radical generator and as a film-forming polymer 55 parts by mass of a 20% by mass methyl ethyl ketone solution of polyester polyurethane resin A was mixed, and 0.5 parts by mass of black dye (product name: NUBIAN BLACK, manufactured by ORIENT Industry Co., Ltd.) was further dispersed and stirred to obtain an adhesive Components of the binder resin solution.

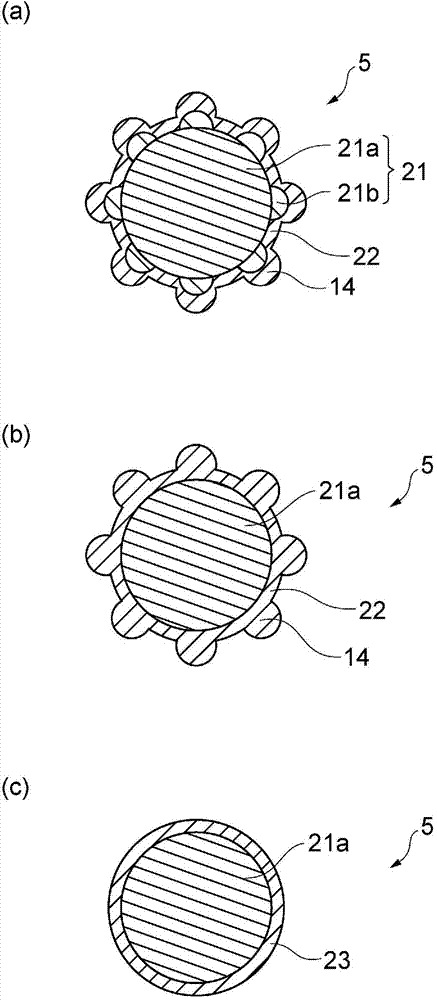

[0136] Furthermore, conductive particles (average particle diameter: 3 μm) having an outermost layer containing Ni and having polystyrene particles as a core body and a coated core body and having protrusions formed on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com