Modeling method of conical casting

A conical casting technology, applied in the field of casting molding, can solve the problems of difficult operation of conical products, high labor intensity, inaccurate model size, etc., and achieve the effect of solving difficult molding, convenient sand filling, and low sand core height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

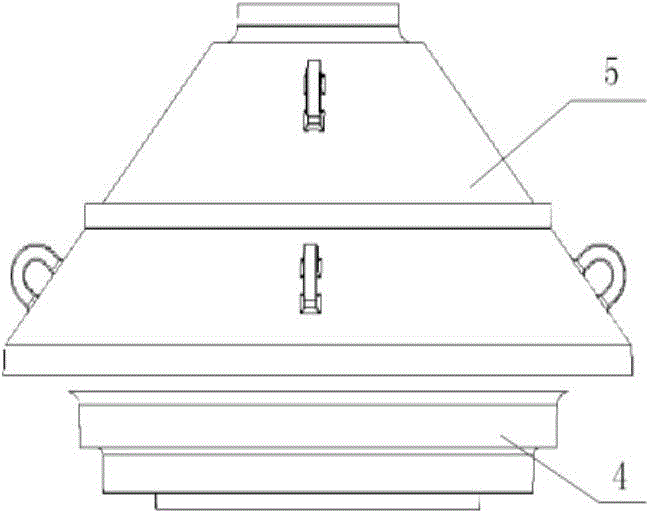

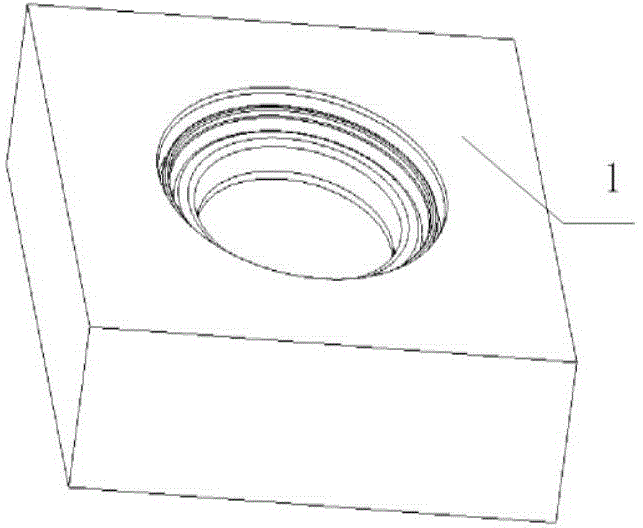

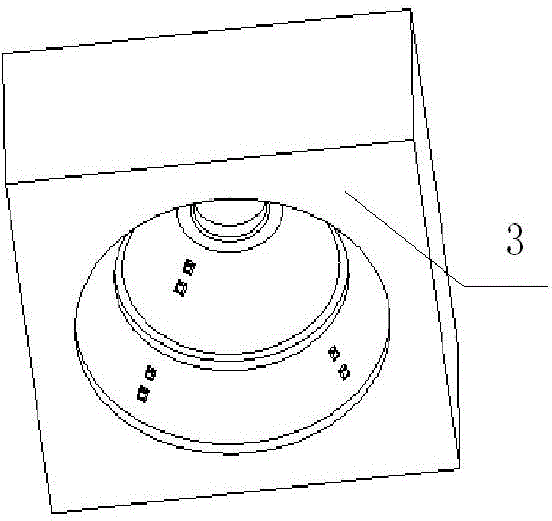

[0029] 1. A molding method for conical castings, such as figure 1 , 2 , 3, 4, 5, 6, and 7: the method comprises the steps:

[0030] a. Place the lower half pattern 4 upside down in the sand box, adjust the position, and pour molding sand into the sand box to prepare the lower half sand mold 1;

[0031] b. After the molding sand is hardened, turn over the lower half sand mold 1 and the lower half pattern 4;

[0032] c. Place the upper half pattern 5 on the lower half pattern 4, adjust the position, and prepare the upper half sand mold 3;

[0033] d. After the molding sand is hardened, the upper half of the sand mold 3 is raised, and the upper half of the pattern 5 and the lower half of the pattern 4 are taken out;

[0034] e. Preparation of sand core 2: pour molding sand into the core box 6 and scrape it flat; take out sand core 2-a after the molding sand is hardened; repeat the above operation to prepare sand core 2-b;

[0035] f. Place the prepared sand core 2 in the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com