Operating device and method for connecting rod crosshead assembly of marine low-speed diesel engine

A crosshead assembly and operating device technology, which is applied to tool storage devices, workbenches, metal processing, etc., can solve the problems of delayed production progress, poor flexibility, and high inefficiency of operating pit occupation, and achieve flexible and reduced installation areas. Time-consuming, simple and efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited thereby.

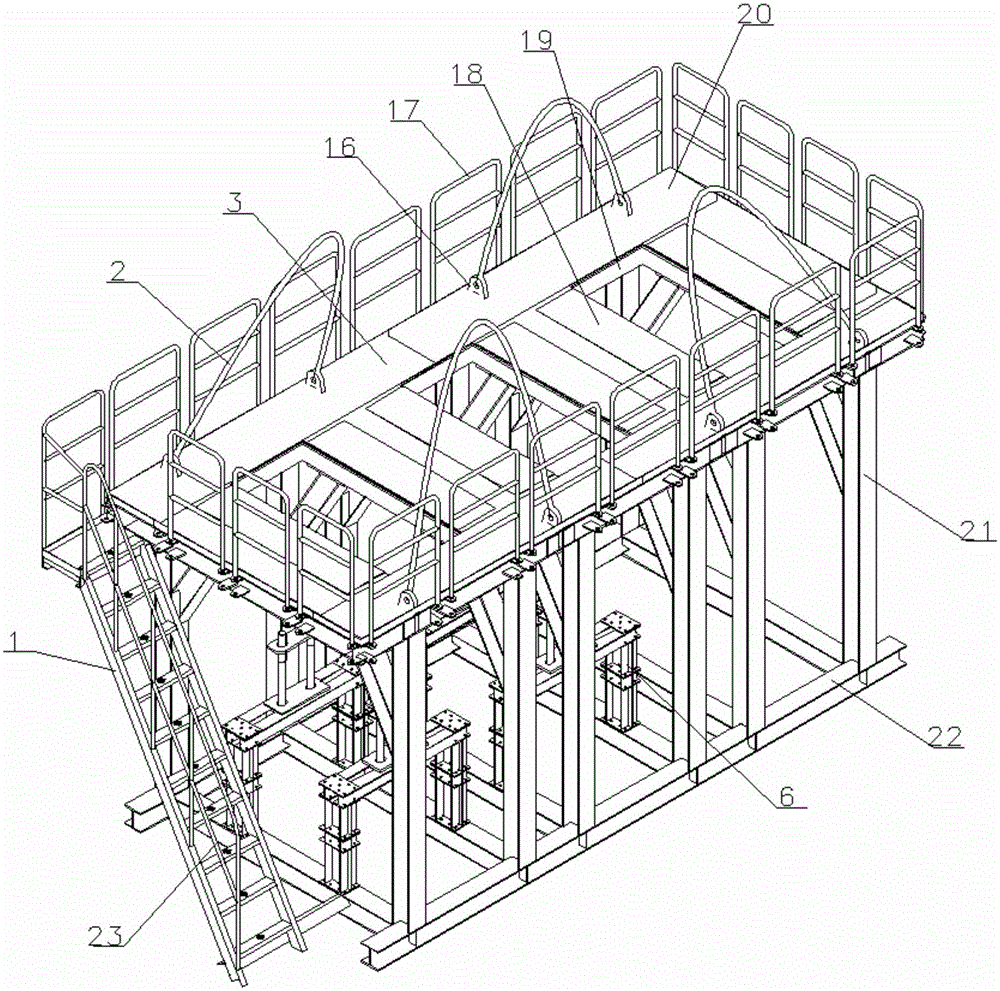

[0042] see figure 2 , the operating device of the marine low-speed diesel engine connecting rod crosshead assembly includes a connecting rod transfer frame 3, which includes a working platform 20, a platform base 22, a number of lifting wire ropes 2 and climbing stairs 1. The working platform 20 is provided with a plurality of holding holes 19, and the number of the holding holes 19 in this embodiment is 3, which are used to pass the connecting rod crosshead assembly, that is, this embodiment can place 3 connecting rod crosshead assemblies at the same time. Rod crosshead assembly, the periphery of the work platform 20 is provided with a platform guardrail 17 to ensure the safety of the operator. A skid 18 is provided on the side of each holding hole 19 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com