An electrophoresis multifunctional fixture for three-package parts of automobiles

A three-pack, multi-functional technology, applied in the field of three-pack electrophoresis multi-function fixtures for automobiles, can solve the problems of peeling paint film, the electric paint film cannot reach the specified thickness, and the three-pack parts are not firmly fixed, and can meet the needs of use. Requirements, protection of long-term development, to solve the effect of poor electrophoresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

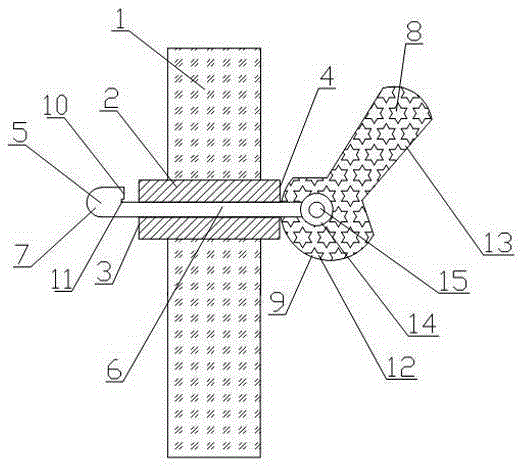

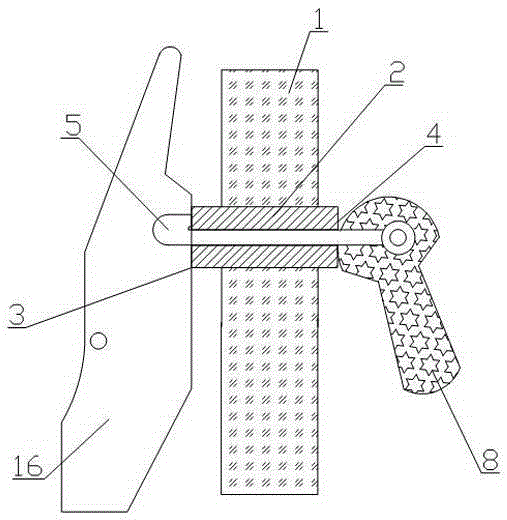

[0024] exist figure 1In the shown embodiment, a three-pack electrophoresis multifunctional fixture for automobiles includes a spreader column 1 cooperating with the electrophoresis spreader, the spreader column 1 is fixedly connected with the electrophoresis spreader and forms a cathode power circuit, and the spreader column 1 is provided with a plurality of hook pin sleeves 2 matching the position and center of gravity of the three-package parts process, the hook pin sleeves 2 are vertically arranged horizontally to the spreader column 1, and the hook pin sleeves 2 are provided with a clamping surface 3 and a supporting surface 4 , the clamping surface 3 and the supporting surface 4 respectively extend out from the two sides of the spreader column 1, and the inside of the hook pin sleeve 2 is provided with a clamping hook 5, and the hook handle 6 of the clamping hook 5 passes through the hook pin sleeve 2 and the clamping handle. 8 Rotational connection, the hook end 7 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com