Transitional junction from concrete-filled steel tube combination column to reinforced concrete column

A technology for reinforced concrete columns and concrete-filled steel tubes, which is applied in the field of nodes transitioning from concrete-filled steel tubular composite columns to concrete columns, can solve the problems of difficulty in bundling and positioning of steel bars, sudden changes in stiffness and bearing capacity, and poor concrete pouring and tamping, so as to meet the requirements of earthquake resistance Performance requirements, avoiding sudden changes in stiffness and bearing capacity, and the effect of simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

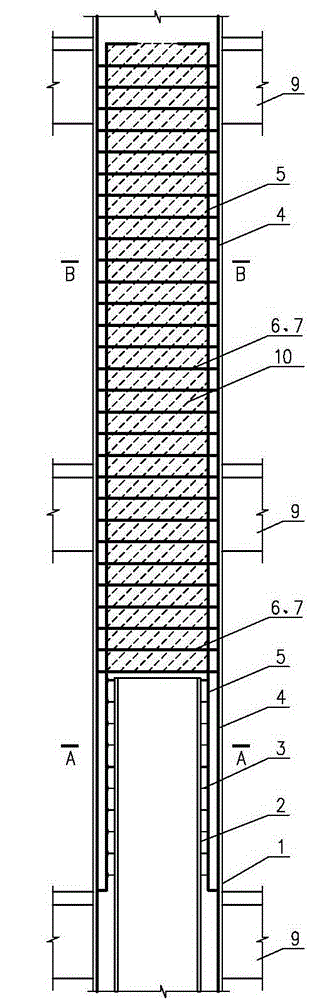

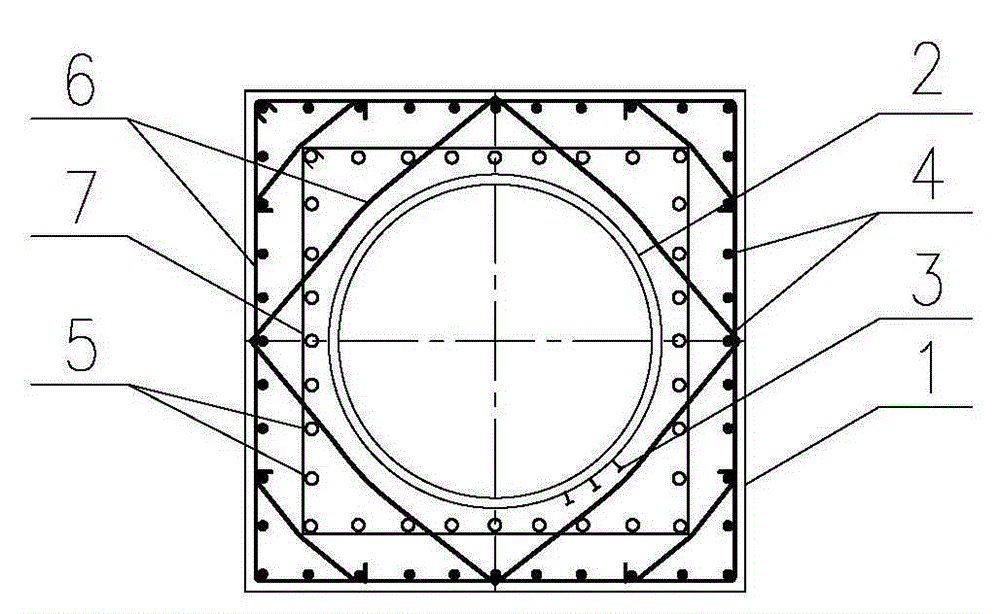

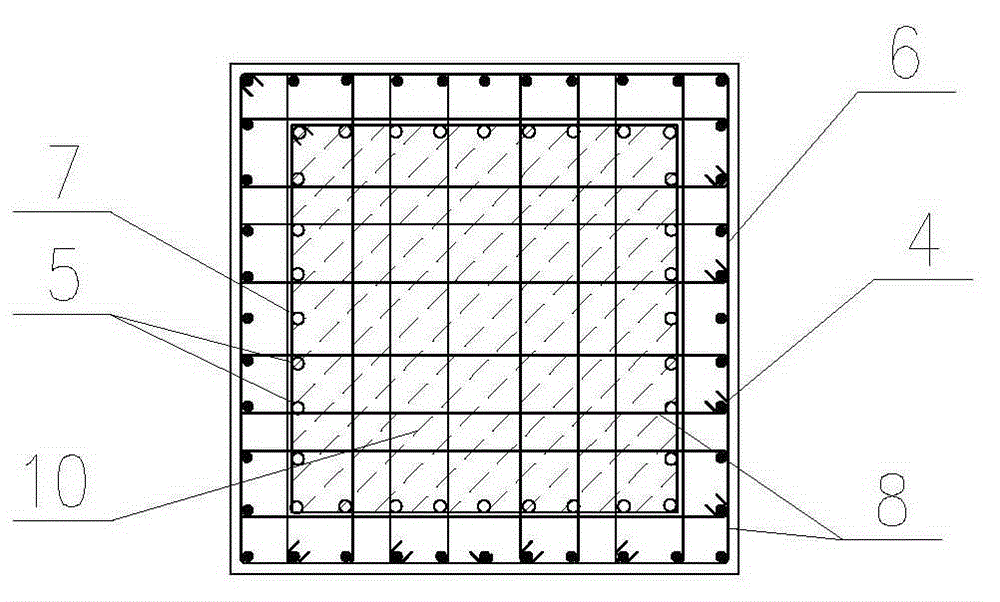

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] The details of the column body of a steel pipe concrete composite column to a reinforced concrete column transition node used in high-rise and super high-rise buildings according to the present invention are as follows figure 1 shown. Among them, the cross section of the steel pipe concrete composite column is rectangular, and the steel pipe 2 is arranged in the concrete column 1, and the cross section of the steel pipe 2 is circular. Afterwards, the steel pipe 2 extends upwards from the floor to the middle of the floor and is cut off. The steel pipe 2 is no longer installed on the upper floors. The steel pipe 2 is set in the center of the concrete column 1. The minimum distance is 200mm. Set the core column longitudinal reinforcement 5 and the core column stirrup 7 on the transitional floor, and extend upward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com