Bag type grouting anchoring device and anchoring method

An anchoring device and grouting technology, which is applied to earth-moving drilling, bolt installation, mining equipment, etc., can solve the problems of inability to fix the bolt, and achieve the effects of improving the anchoring effect, rational utilization of materials, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

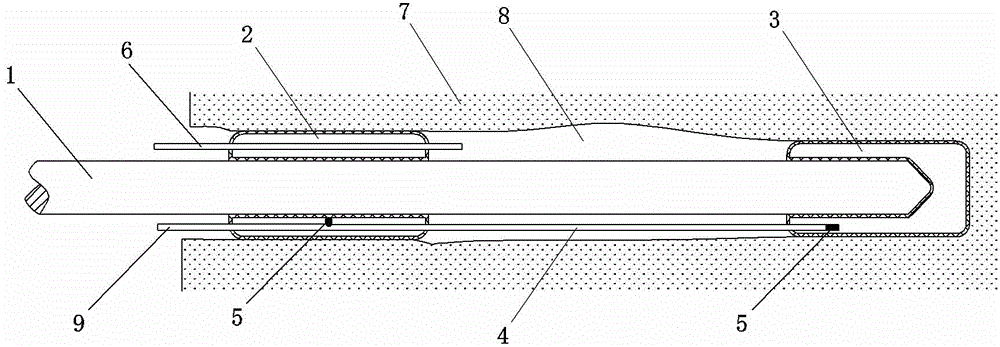

[0011] Embodiment 1: see figure 1 , the first bag-type grouting anchoring device and anchoring method is that the front and rear ends of the anchor rod 1 are respectively sleeved with a front annular expansion bag 3 and a rear annular expansion bag 2, and there is an end between the front and rear annular expansion bags. Grouting gap 8. The front and rear annular expansion bags communicate with the first grouting pipe 4 respectively, and the grouting gap 8 communicates with the second grouting pipe 6 .

[0012] The grouting opening 9 of the first grouting pipe 4 is located at the end of the anchor rod 1, and the first grouting pipe 4 is connected to the inner cavity of the front and rear annular expansion bags respectively. In this embodiment, a one-way valve 5 is arranged on the first grouting pipe 4, and the one-way valve 5 is arranged at the grout outlet in the front and rear annular expansion bags.

Embodiment 2

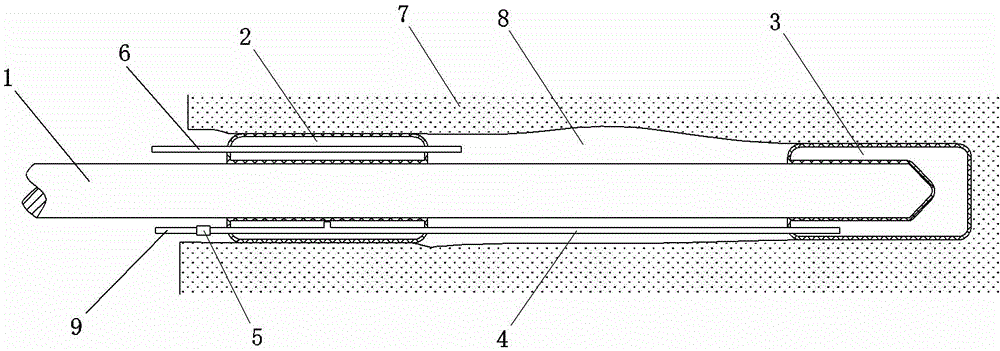

[0013] Example 2: see figure 2 , the second bag-type grouting anchoring device and anchoring method are basically the same as in Embodiment 1, except that the one-way valve 5 is set at the position of the grouting port 9 of the first grouting pipe 4 .

Embodiment 3

[0014] Embodiment 3: The drawings are not drawn, the content is basically the same as that of Embodiment 1, the difference is: no one-way valve is set on the first grouting pipe, when in use, only need to keep the first grouting pipe with sufficient pressure In order to stretch the front and rear annular expansion bags. After the second grouting pipe injects grout into the grouting gap and solidifies, the first grouting pipe can no longer be tested for pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com