Improved toner barrel

A technology of toner cartridges and cartridges, which is applied in the fields of electrical recording technology using charge graphics, equipment using electrical recording technology using charge graphics, and electrical recording techniques, which can solve the problems of increasing machine rotation resistance, unsmooth powder feeding, and carbon powder Powder mixing and other problems can be achieved to reduce rotational resistance, increase service life, and increase fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

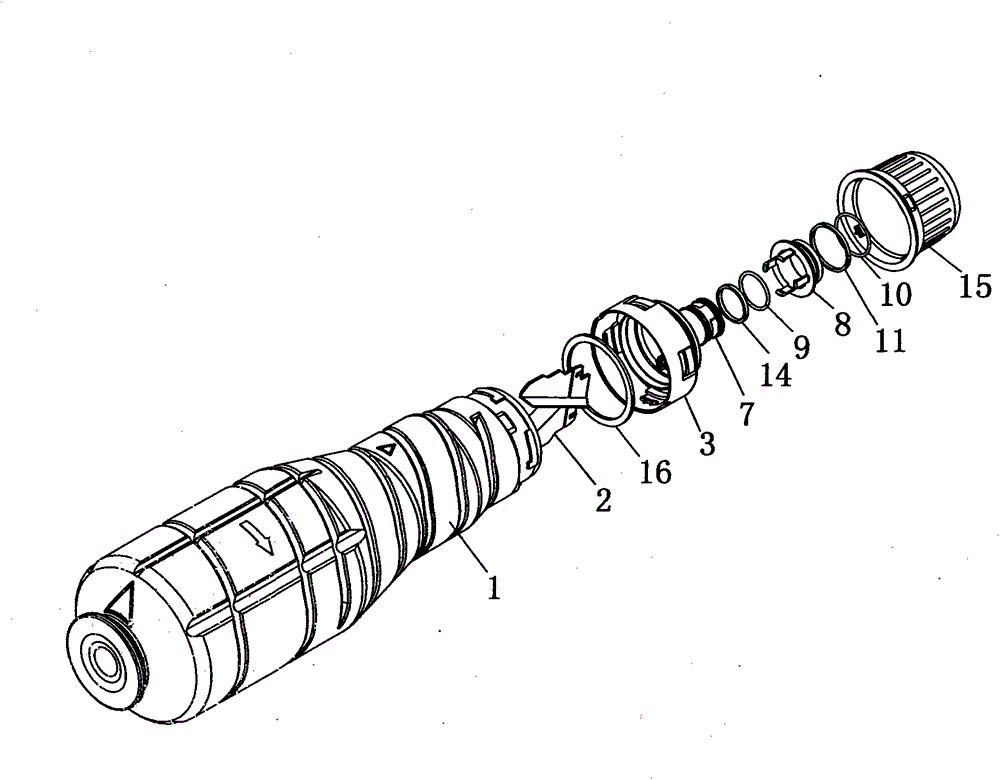

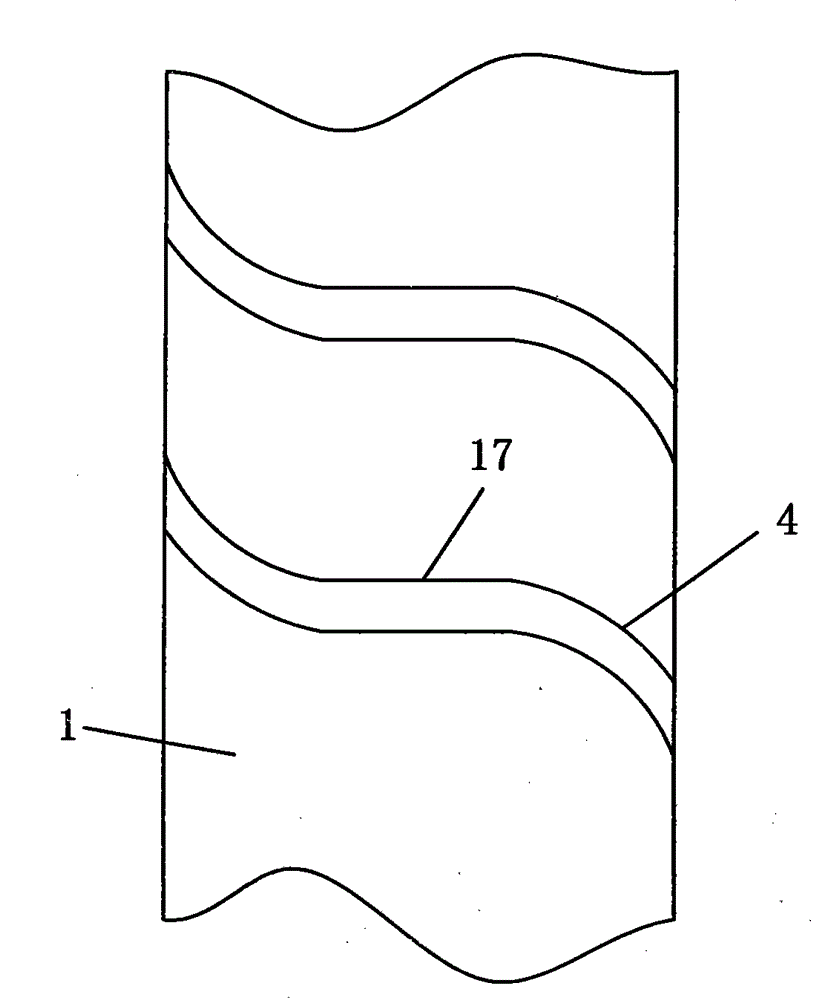

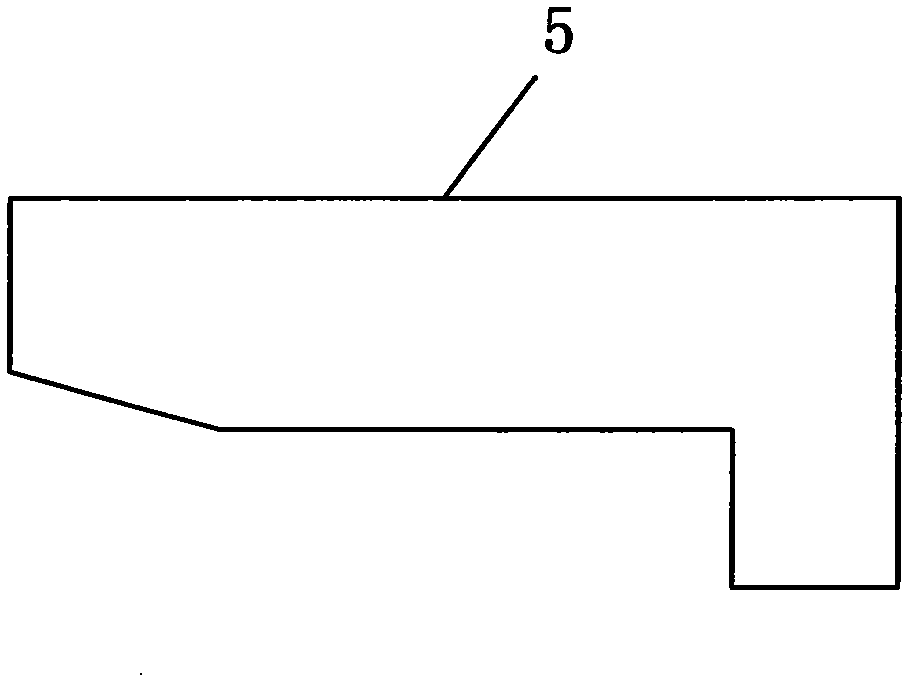

[0027] Reference Figure 1-6 The structure of the present invention includes an improved carbon powder cartridge, which includes a cylinder body 1, a powder feeding sheet 2 is arranged inside the cylinder body 1, a top cover 3 is provided on the top of the cylinder body 1, and the cylinder body 1 The surface is provided with a T-shaped spiral groove 4; the bottom of the top cover 3 is provided with an L-shaped thread 5 and at least one backstop groove 6, the upper part of the top cover 3 is provided with a powder outlet 7, and the outside of the powder outlet 7 is provided with The powder outlet sealing ring 8 is provided with a second sealing ring 10 and a third sealing ring 11 on the upper part of the powder outlet sealing ring 8, and a first sealing ring 9 and a fourth sealing ring 14 are also provided outside the powder outlet 7.

[0028] It is worth noting that a number of horizontal grooves 17 are provided in the T-shaped spiral groove 4, and the horizontal grooves 17 are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com