Single-layer capacitive two-dimensional touch sensor with mutually crossed adjacent electrodes

A touch sensor, adjacent electrode technology, applied in the direction of instrument, electrical digital data processing, input/output process of data processing, etc., can solve the problems of limited contact area, poor linearity, inability to implement mobile phones, etc., to overcome the contact area Limited, improved linearity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

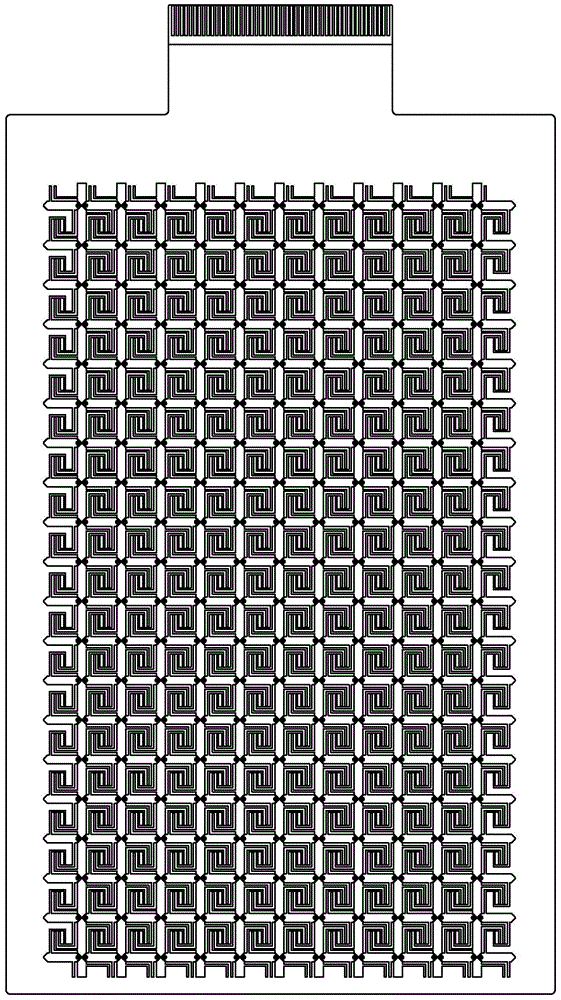

[0034] Figure 1A The schematic diagram of the overall wiring of the two-dimensional touch sensor provided for the first embodiment, due to the dense wiring, is especially enlarged by selecting the shape of some sensing electrodes and driving electrode blocks, specifically as follows Figure 1B to Figure 1D shown in detail below.

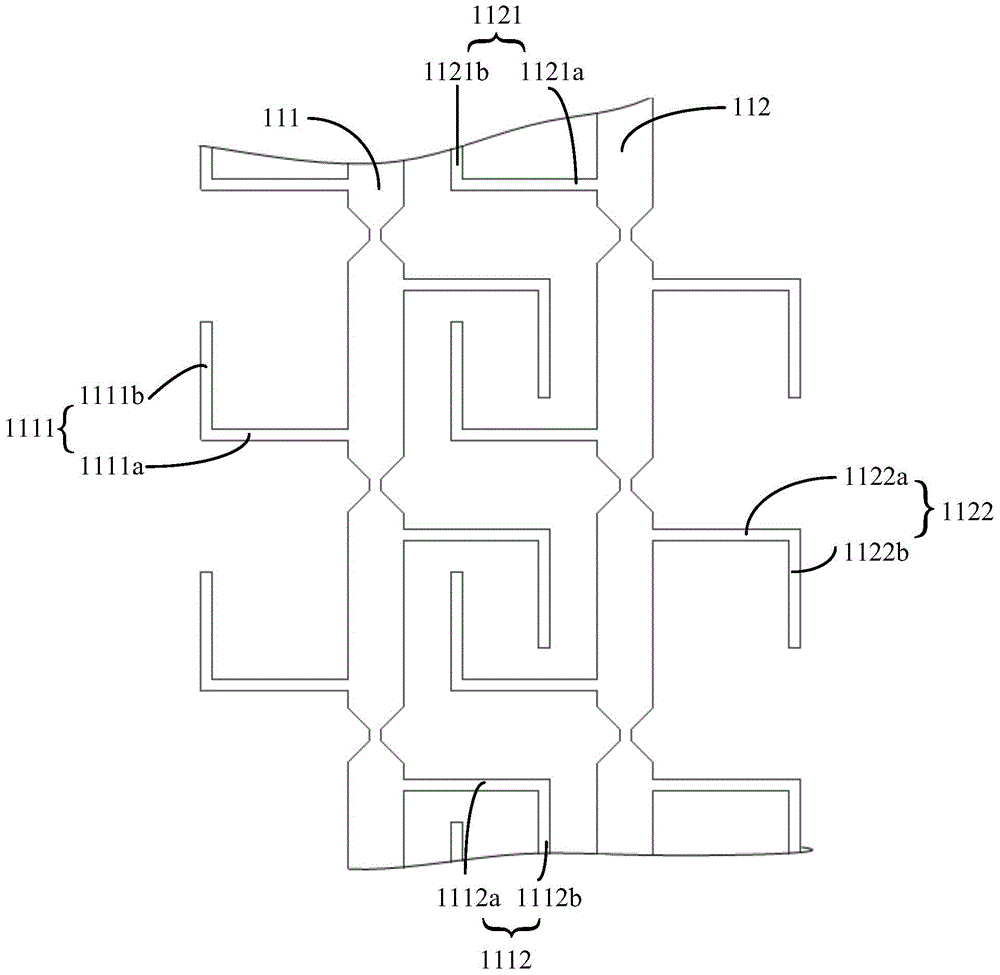

[0035] refer to Figure 1B , each sensing electrode includes the sensing electrode body, Figure 1B The adjacent sensing electrode bodies 111 and 112 are shown. The sensing electrode body has several extensions bent at least once on both sides respectively, and among the several extensions bent at least once on each side, the latter The bending parts are all bent at the ends of the previous bending part in a direction perpendicular to the previous bending part, and the directions of the most end bending parts on both sides are opposite. Figure 1BTwo bending parts are taken as an example in the figure. The sensing electrode body 111 has an extensi...

Embodiment 2

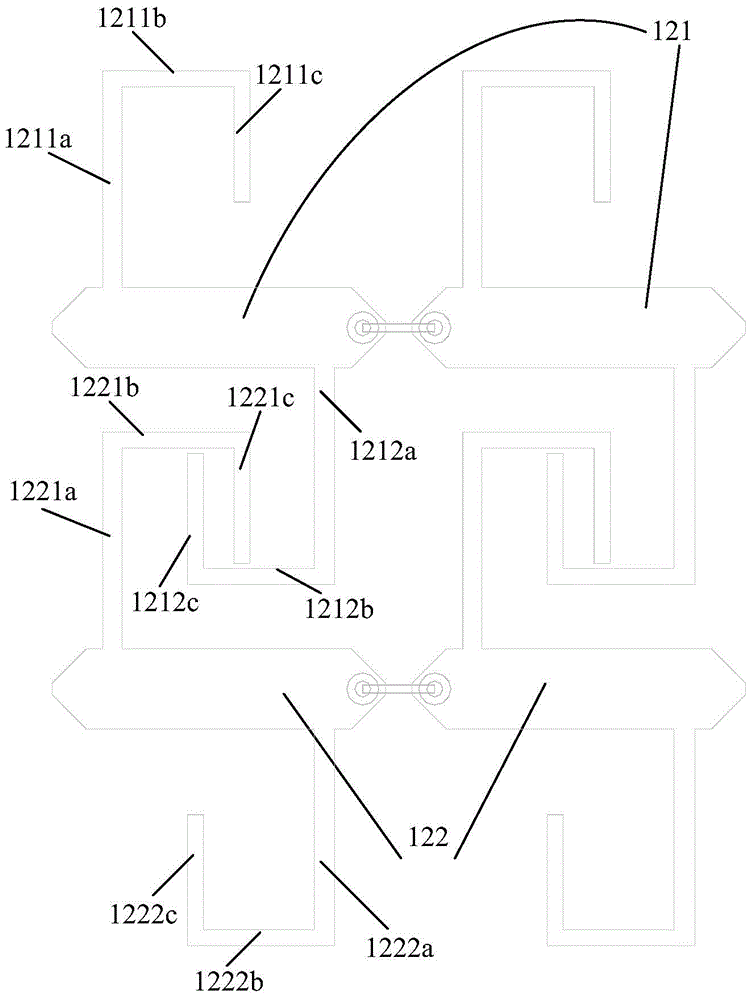

[0041] The design of embodiment two is similar to embodiment one, by Figure 2A with Figure 2B It can be seen that the difference is that in the second embodiment, the sensing electrode and the driving electrode block have one more bending part than in the first embodiment, and in the first embodiment, the sensing electrode has two bending parts, and the driving electrode block has three bending parts. , while in the second embodiment, there are three and four respectively. In addition, the direction of bending is also opposite. No more details.

Embodiment 3

[0043] refer to Figure 3A , each sensing electrode includes a sensing electrode body, the sensing electrode body has an extension to its two sides, the extensions of two adjacent sensing electrodes cross each other but do not touch each other, such as the left side of the sensing electrode body 311 has several extensions The portion 3111 has several extensions 3112 to the right, and the sensing electrode body 312 has several extensions 3121 to the left and several extensions 3122 to the right. The extensions 3112 and 3121 cross each other but do not touch each other.

[0044] refer to Figure 3B , each driving electrode block includes a driving electrode block body, and the driving electrode block bodies 321 and 322 respectively have extensions that are bent twice from the two ends as starting points to both sides, such as the left end point of the driving electrode block body 321 facing down and then Bending to the right, the right end point of the driving electrode block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com