Method of manufacturing camshaft

A technology of camshafts and cams, which is applied in the field of manufacturing camshafts, and can solve problems such as product errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

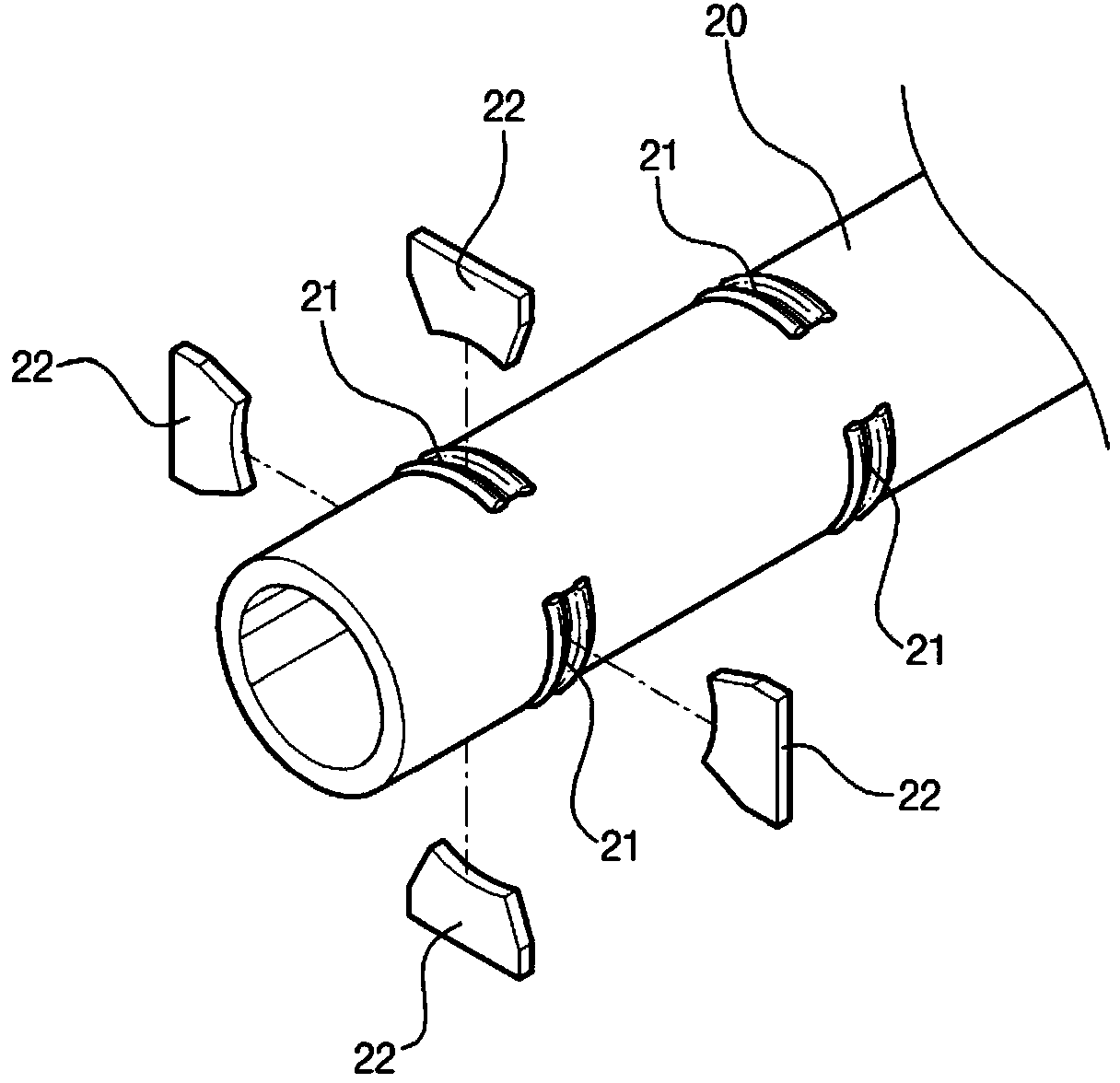

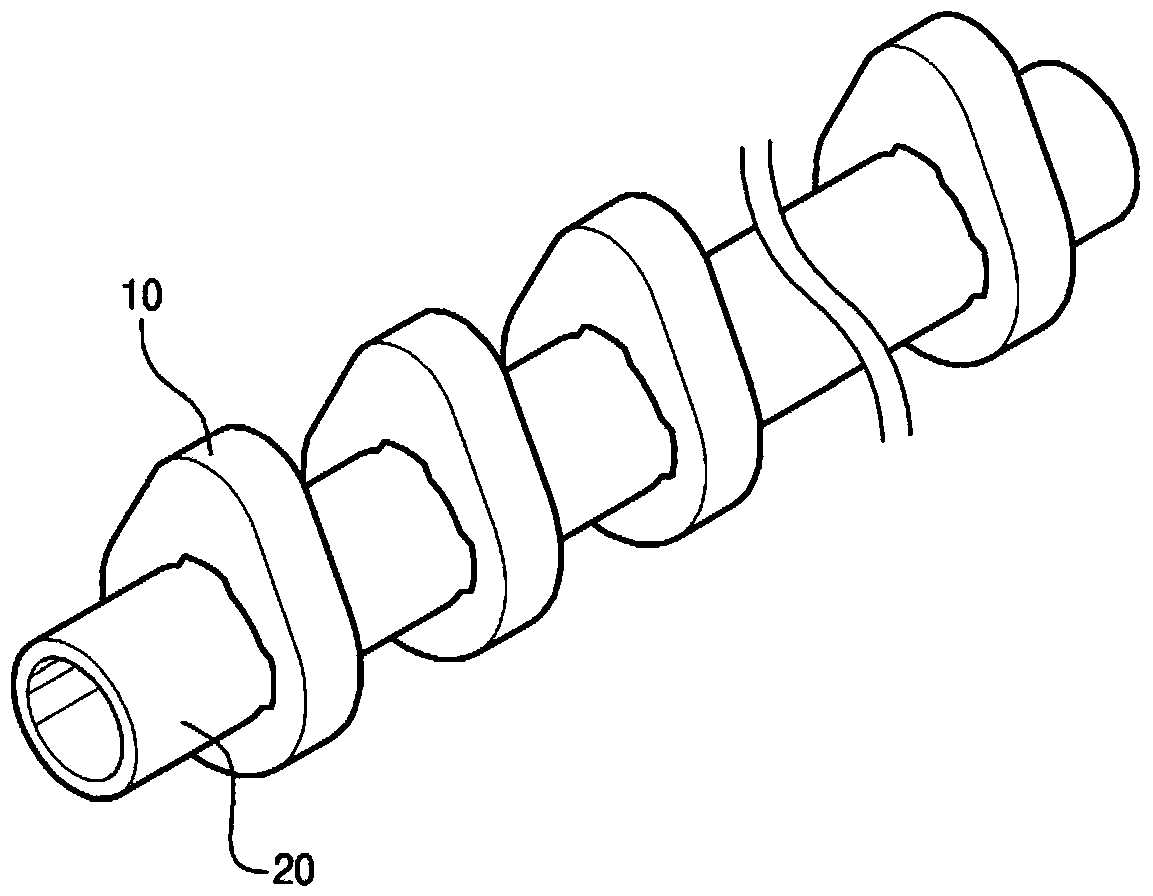

[0040] The method of manufacturing a camshaft according to the present invention includes manufacturing a cam 10 having a recess 12 formed therein, and fastening the cam 10 to a shaft 20 having a protrusion 21 in such a manner that either the cam 10 or the shaft 20 rotates relative to the other. After fastening, the cam 10 is joined to the shaft 20 by brazing rather than sintering.

[0041] 【Manufacture of cams by main sintering】

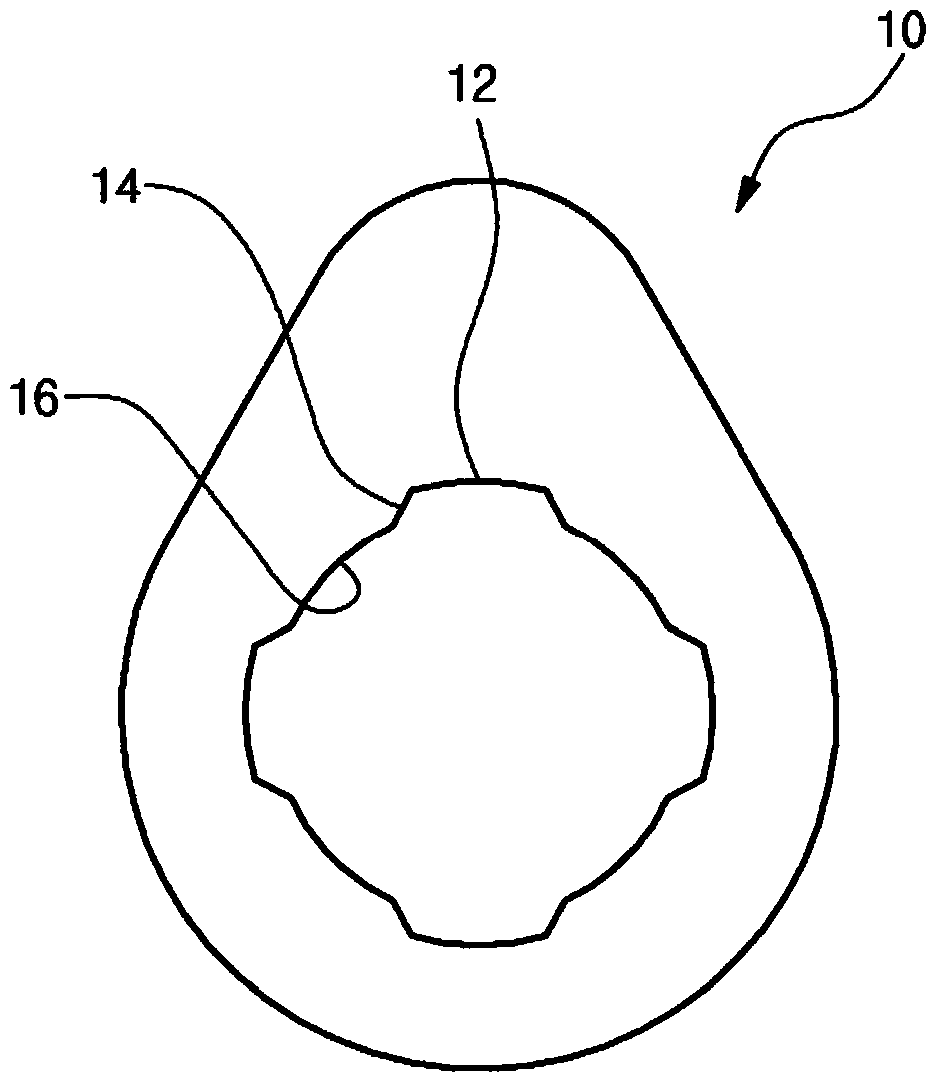

[0042] figure 1 A cam 10 with a recess 12 according to the invention is shown.

[0043] The circumferential inner surface of the cam 10 includes a recess 12 forming a larger diameter and a small diameter portion 16 . A slope 14 is formed between each recess 12 and the adjacent small-diameter portion 16 .

[0044] After forming the cam 10 with the recess 12, the cam 10 with the recess 12 is sintered. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com