Rotary type stirrup automatic collecting device

A rotary and stirrup technology is applied in the field of automatic stirrup collecting devices, which can solve the problems of not being able to adapt to the speed of the automatic steel bar hoop bending machine to produce stirrups, affecting the production efficiency of the steel bar automatic hoop bending machine, and high labor intensity. Achieve the effect of simple structure, safe use and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

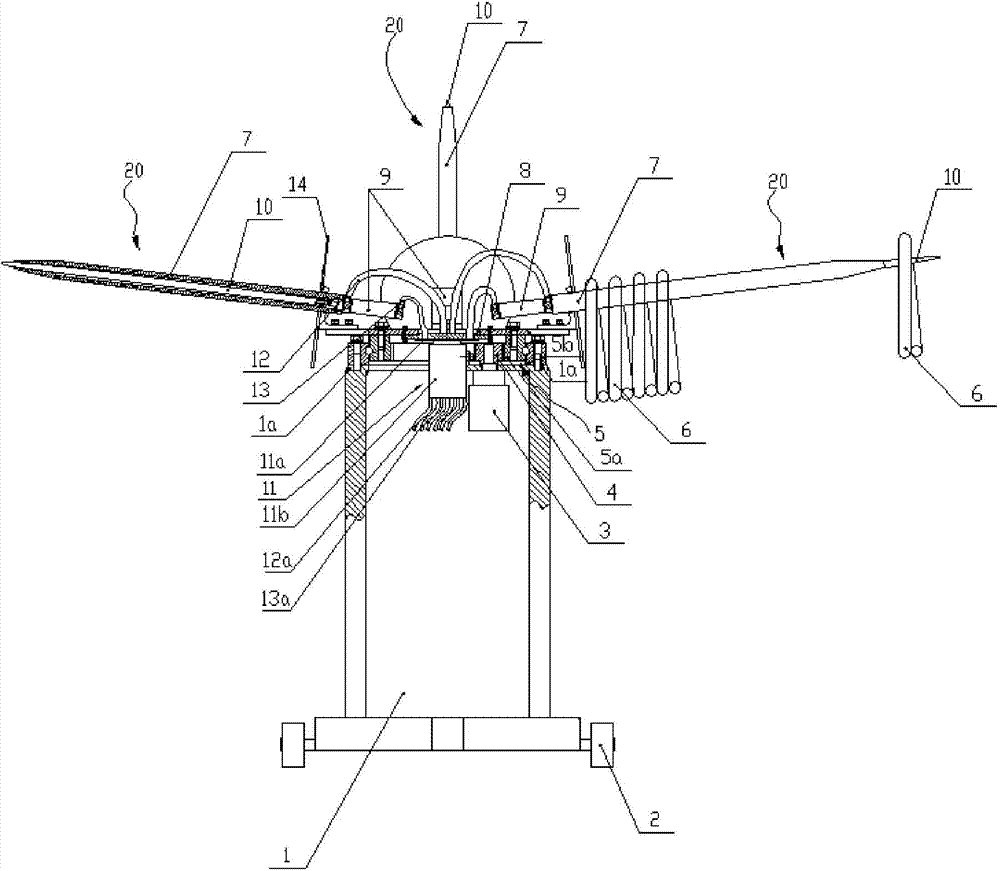

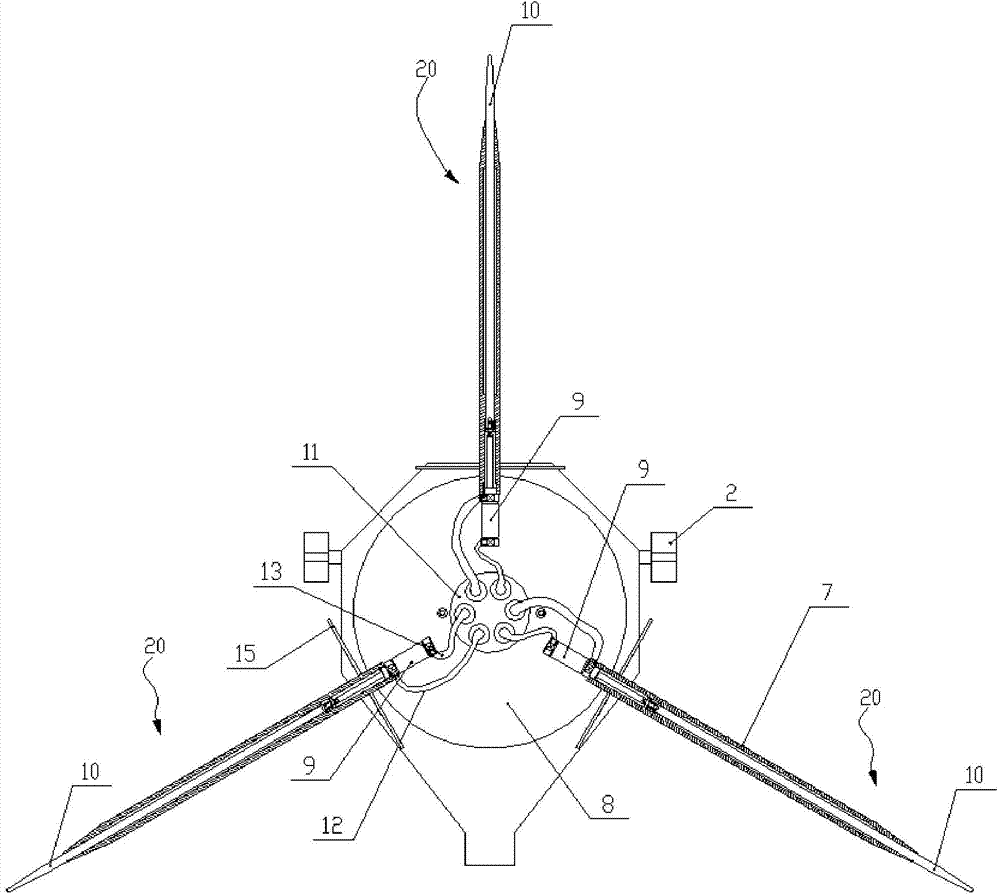

[0017] figure 1 is a schematic front view of the present invention; figure 2 Yes figure 1 top view.

[0018] As shown in the figure, the present invention provides a rotary automatic device for collecting stirrups. The device for automatically collecting stirrups includes: a frame 1, multiple devices for collecting stirrups 20 with the same structure; The rib device 20 is installed on a rotating mechanism at intervals, and the rotating mechanism includes: a motor reducer 3 is fixed on the upper bracket 1a of the frame on the upper part of the frame 1, and the pinion 4 on the output shaft of the motor reducer 3 meshes and rotates The inner teeth of the inner ring 5a of the bearing 5 and the outer ring 5b of the rotary bearing 5 are fixed on the upper bracket 1a of the frame; A stirrup collecting device 20; the motor reducer 3 drives the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap