Hand braking control mechanism of roller tractor

A wheeled tractor and control mechanism technology, which is applied in the field of wheel tractor hand brake control mechanism, can solve the problems that the manual control mechanism cannot perform emergency braking and the pedal brake control mechanism cannot be independent of each other, and achieve structural Reasonable, the effect of improving the reliability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

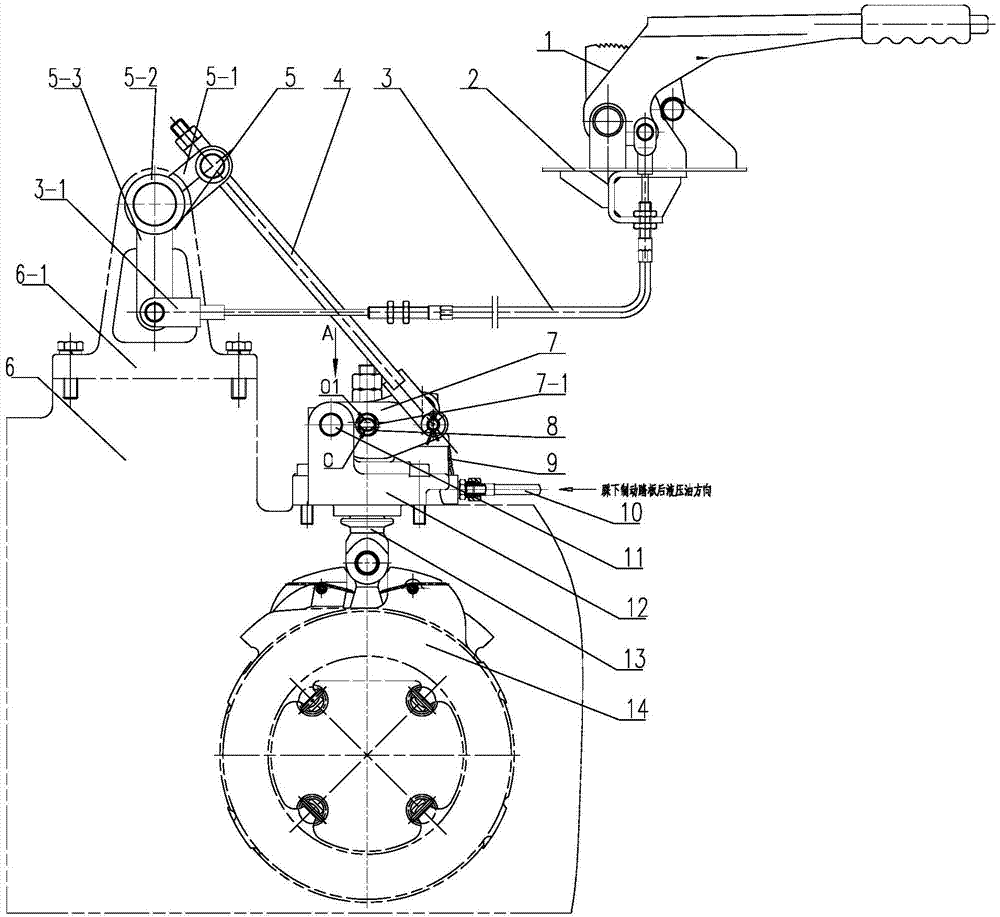

[0012] see figure 1 As shown, the wheeled tractor hand brake operating mechanism of the present invention includes a hand brake 1 and a hand brake cable 3 with one end hinged on the hand brake 1. The hand brake 1 is an existing commercially available hand brake, and the hand brake 1 is installed On the bottom plate 2, when the parking brake is applied, the handle is rotated along its hinged center and locked on the corresponding tooth plate by a ratchet.

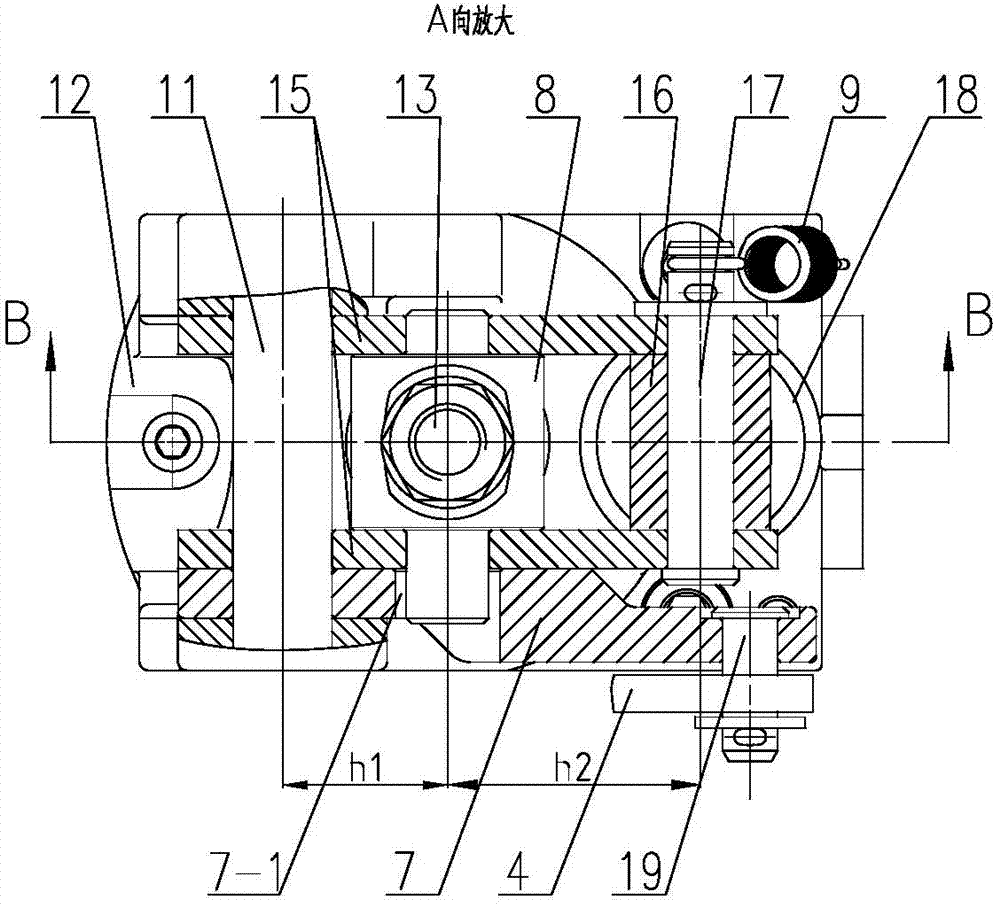

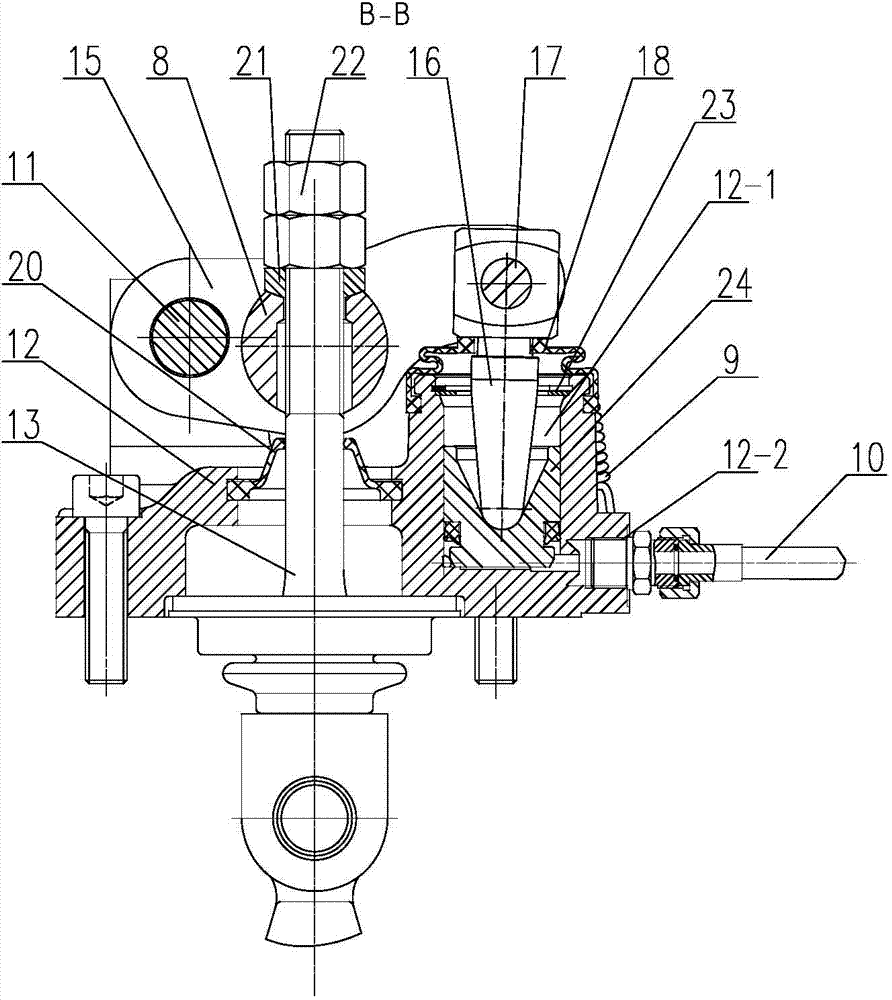

[0013] see Figure 1~4 As shown, the present invention also has a rocker arm assembly 5, a hand brake lever 4 and a brake connection assembly. The brake connection assembly of the present invention includes a brake seat 12, two brake rocker arms 15, a hand brake rocker arm 7, a piston 24, a pull shaft 8 and a brake lever 13, and two brake rocker arms 15 and a hand brake rocker arm 7 One side is rotatably connected to the brake seat 12 through the shaft 11, so both the hand brake rocker arm 7 and the brake rocker arm 15 can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com