Radial turbulence preventing ship propeller

A propeller and anti-interference technology, applied in the direction of rotating propellers, rotary propellers, etc., can solve the problems of unseen ship propellers, cavitation generated by propeller blades, and reduced propeller efficiency, so as to reduce vibration and noise, reduce blade Slightly cavitating, the effect of improving concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

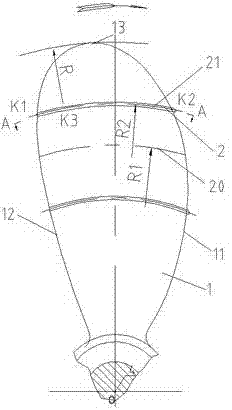

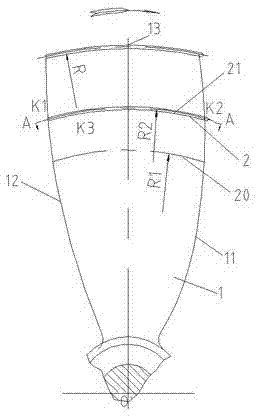

[0021] The anti-disturbance strip 2 of the present invention is arranged on all the blades of the ship propeller, figure 1 with figure 2 Shown is the anti-disturbance strip for one blade of a marine propeller. Looking from the stern to the bow, the propeller rotation indicated by the arrow is clockwise.

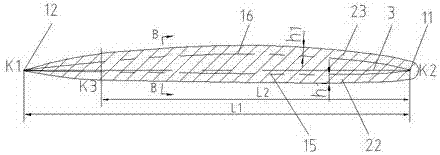

[0022] figure 1 with figure 2 Among them, at the arc position with the 4th axis of the propeller shaft as the center and R1 or R2 as the radius, the arc K1K2 obtained by intersecting R2 with the propeller trailing edge 12 at point K1 and intersecting with the propeller leading edge 11 at point K2 , 1 to 2 anti-disturbance strips 2 protrude laterally at the arc K1K2. The anti-disturbance strip 2 includes the blade surface anti-disturbance strip 22 and the blade back anti-disturbance strip 23. The center line 21 of the anti-distur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com