A core wire break detection device

A broken wire detection and core-spun wire technology is applied in the directions of transportation and packaging, transportation of filamentous materials, thin material handling, etc. Visual inspection effect, reduction of non-uniformity, effect of protecting core-spun wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

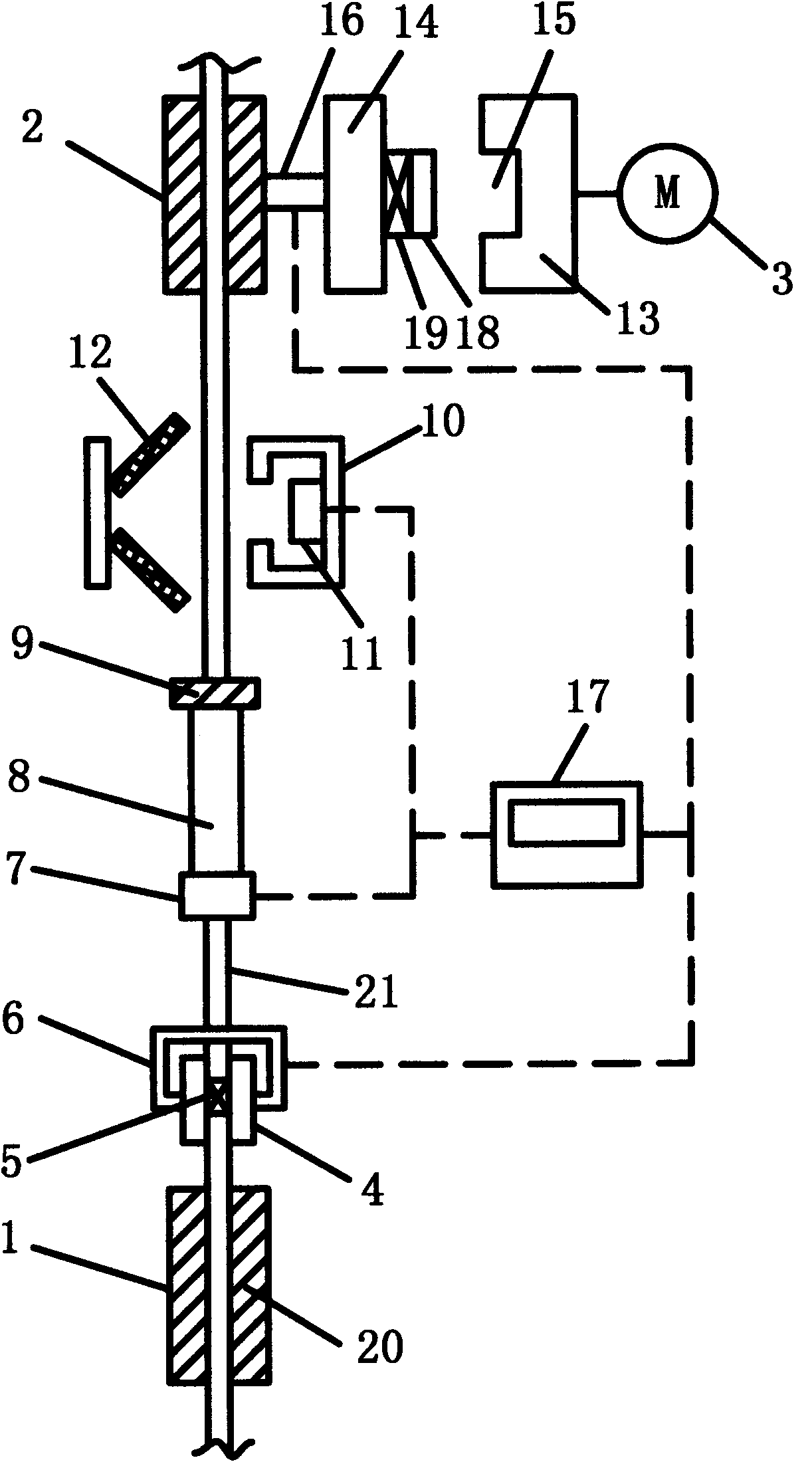

[0031] refer to figure 1 , this embodiment includes a driven transmission wheel 1 and a driving transmission wheel 2, a tension regulator and a broken wire detector are arranged between the driven transmission wheel 1 and the driving transmission wheel 2, and the driving transmission wheel 2 passes through the transmission and the motor 3 connected, the tension regulator includes two rubber friction plates 4 symmetrically arranged, a first spring 5 is arranged between the two rubber friction plates 4, and a hydraulic buckle 6 is arranged on the outside of the two rubber friction plates 4, and the disconnection The detector includes a mechanical detector and a visual detector arranged in series, the mechanical detector includes a microswitch 7, the microswitch 7 is connected with a supporting arc arm 8, and the top of the supporting arc arm 8 is provided with a pulley 9, and the visual detector includes a ring A light source 10, a CCD lens 11 is arranged in the middle of the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com