Floor edge-near protective handrail with turnover function

A technology for edge protection and railing, which is applied in construction, building structure, construction material processing, etc., can solve the problems of complicated installation process and material waste, and achieve the effect of long service life, simple process and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

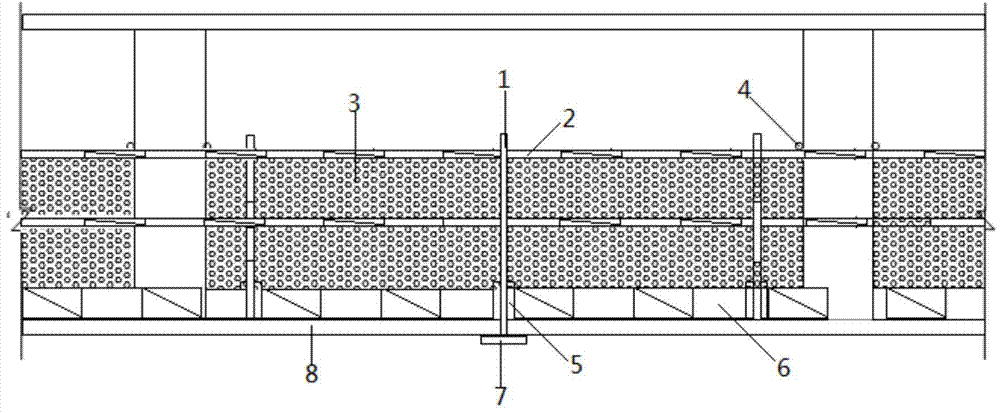

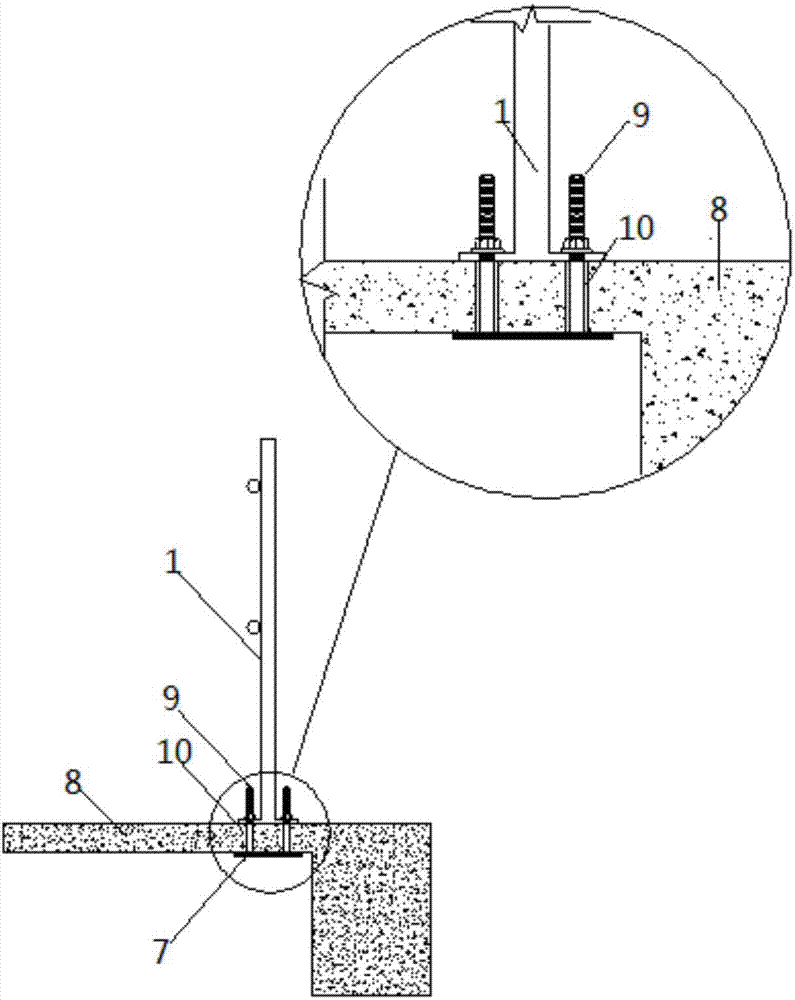

[0015] Referring to the accompanying drawings, the turnaround floor border protection railing includes a concrete structural plate 1, a through hole is opened on the concrete structural plate 8 and a vertical pole 1 passes through it, and the lower two sides of the vertical pole 1 are fixed on the On the kick plate 6, a protective net 3 is fixed on the kick plate 6, and the vertical bar 1 passes through the protective net 3, and the protective net 3 is fixedly installed by a frame composed of a cross bar 2, and the cross bar 2 is fixed by the structural column 4.

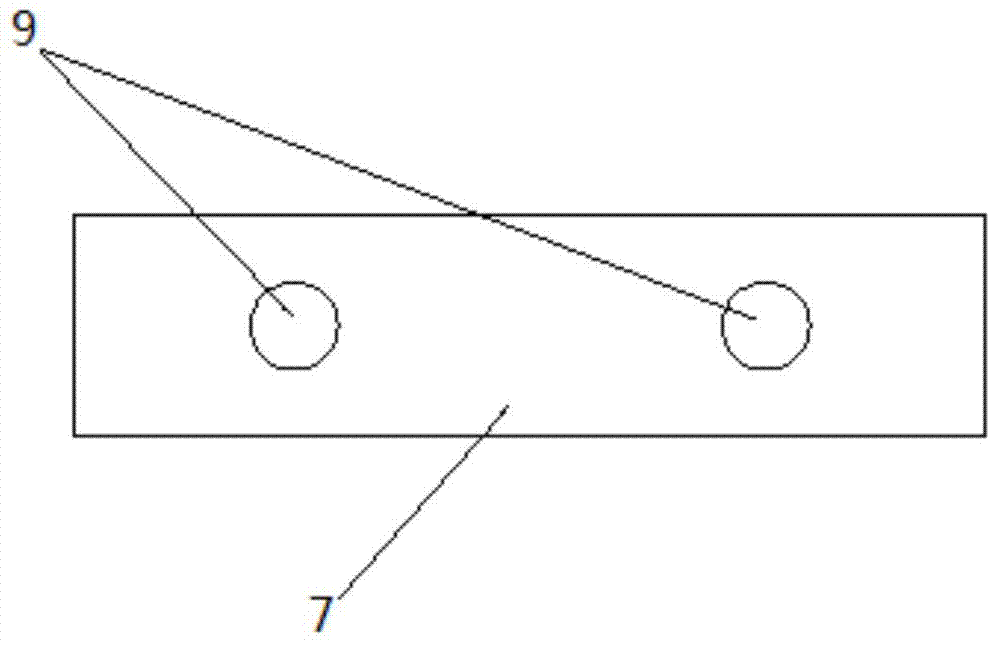

[0016] The bottom of the vertical pole 1 is fixed with the concrete structural plate 8 through the double-pair tension screw 9, the pre-embedded PVC sleeve 10.

[0017] Both sides of the pole 1 are welded with steel pipes 5 with openings, so that the opening steel pipe 5 slots at the bottom of the pole 1 can be inserted into the 10mm concrete structural plate 8 as the skirting board 6 for edge protection.

[0018] s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com