Filling and sealing method of mini-type missile-borne remote measuring device

A telemetry device and miniature technology, which is applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems that the air bubbles of the potting material cannot be effectively discharged, the potting quality cannot be guaranteed, and the position of each functional component is deformed, etc., to improve the product quality. Assembly quality, fast and smooth implementation, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

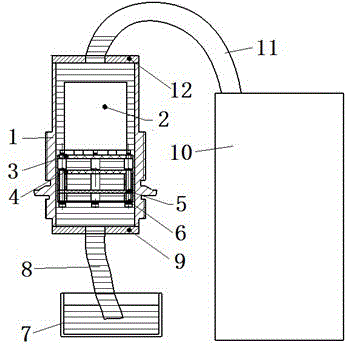

[0019] Such as figure 1 As shown, a method for potting a miniature missile-borne telemetry device, the structure of the miniature missile-borne telemetry device includes a cylindrical shell 1, and the interior of the shell 1 is equipped with a battery 2, a power supply board 3, a data acquisition modulation Board 4, frequency conversion board 5, filter board 6 and other functional modules are potted as a whole. The two ends of the housing 1 are provided with a top cover and a bottom cover. The top cover has a through hole. The signal lines of each functional module Lead out to the outside of the housing through the through hole on the top cover; this method includes the following steps:

[0020] a. Get if figure 1 The potting device of the shown structure, the potting device includes a filling container 7 and a suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com