Stress detection device for rotating member of aero engine

An aero-engine and stress detection technology, applied in the direction of measuring devices, measuring forces, instruments, etc., can solve the problems of cumbersomeness, long detection cycle, poor accuracy, etc., to reduce tooling costs, improve detection quality and accuracy, and reduce potential safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

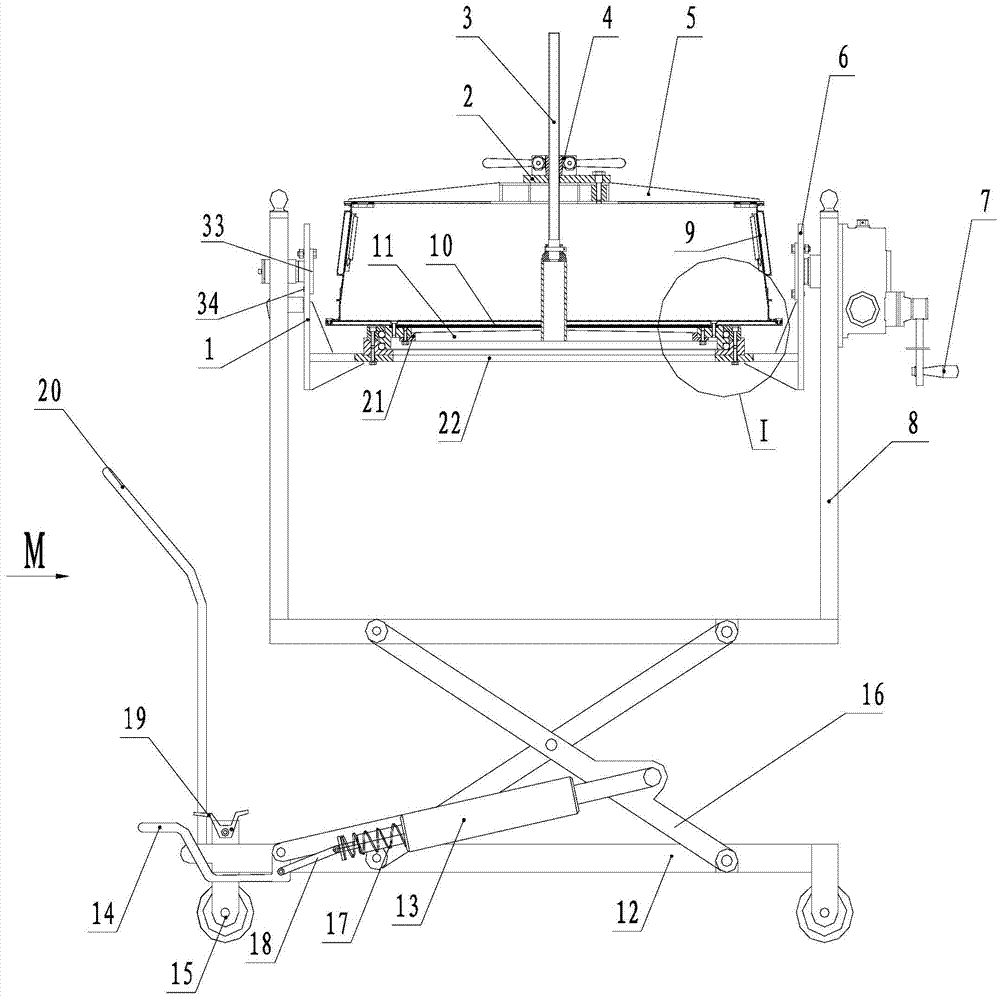

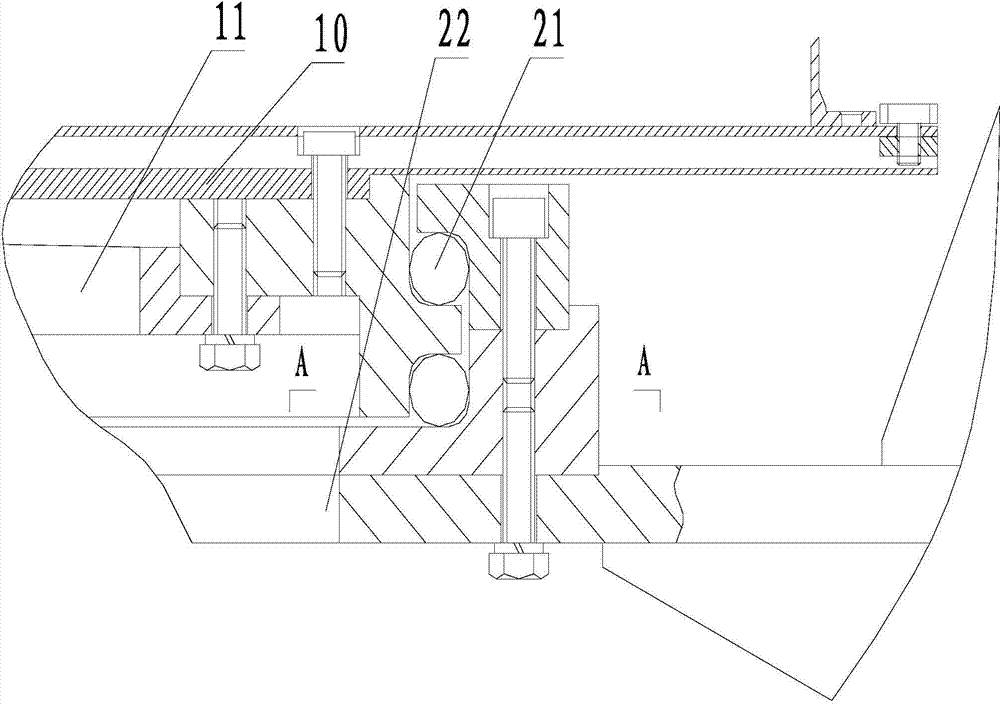

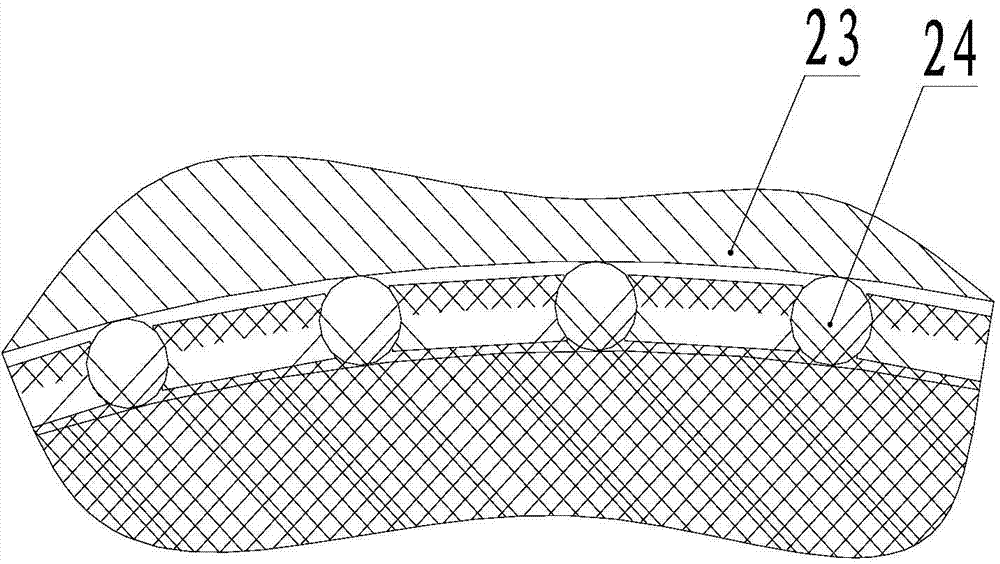

[0026] Such as Figure 1-Figure 11 As shown, a stress detection device for the rotary part of an aero-engine includes a hydraulic platform 12 with movable corner wheels 15 at the bottom, a vehicle frame 8 is arranged above the hydraulic platform 12, and the distance between the vehicle frame 8 and the hydraulic platform 12 is One end of the hydraulic cylinder 13 is hinged with the lifting bracket 16, and the other end is hinged with one end of the adapter block 18. The cylinder body of the hydraulic cylinder 13 is fixed on the hydraulic platform 12; one end of the hydraulic pedal 14 Hinged with the hydraulic platform 12, one end of the hydraulic pedal 14 hinged with the hydraulic platform 12 is hinged with the other end of the adapter block 18, and a return spring 17 is arranged between the hydraulic cylinder 13 and the adapter block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com